Equipment

Taking Apart the Canon RF 600mm f/11 IS STM

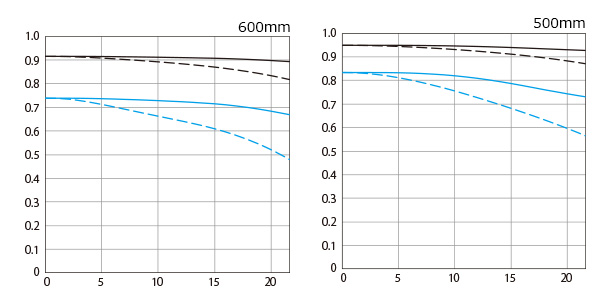

Here I sit, the guy who gets poetic writing about tiny resolution differences in high-priced wide-aperture lenses, having just bought this lens. Its aperture is in the diffraction-softening range. The manufacturer’s (pronounced ‘better than reality’) MTF charts aren’t very good.

600mm f/11 compared to 100-500mm f4.5-7.1 at 500mm, Canon.com

So why did I buy this pig? Because it could fit a need, of course. Despite the religious fervor with which some worship certain lenses and brands, despite my complaints about this lens’ astigmatism or that lens’ corners, it always comes down to ‘does it do the job?’.

I spend a week a month at a vacation home on a lagoon next to a wildlife refuge. Photography is not why I go. It’s downtime and I don’t take a bunch of gear. But sometimes I see really cool birds or reptiles and wish I could get a picture. The reptiles are often alligators, so I wish to take that picture from a distance. So if the Canon RF 600mm f/11 can get me ‘internet acceptable’ images for $699 and 2 pounds, it would be worthwhile. (I rented the camera, I still haven’t committed to a mirrorless system yet. Commitment, well, it’s not my strength.)

Since the lens arrived the day before I left, Aaron suggested we should take it apart and see what’s in there. Besides air. At 2 pounds, there’s going to be a lot of air. I was leaving in a few hours, but we do this all the time, so we were confident. We were, perhaps, even, a tiny bit arrogant, since the only R mount camera we had available was back at my house, packed for the drive. (This here is what we professional writer types call foreshadowing.)

A Quick, “So How’d They Do That?”

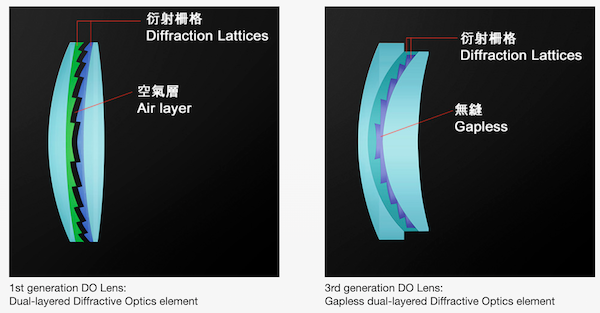

It’s f/11, but it’s still 600mm in a 2-pound package, which is unheard of. They do it with diffraction optics. The same type as the 400mm f/4 IS DO, specifically, the newer ‘gapless’ diffraction optics. This basically is market speak for ‘instead of an air space between the DO elements, we invented some special glue.’

Image from Canon.com technical paper: “Gapless Dual-Layered Diffractive Optical Elements.”

Compared to ‘gapped’ diffraction optics, the gapless design reduces longitudinal chromatic aberration, ring-shaped flare, and improves contrast. Some. You can read about it here.

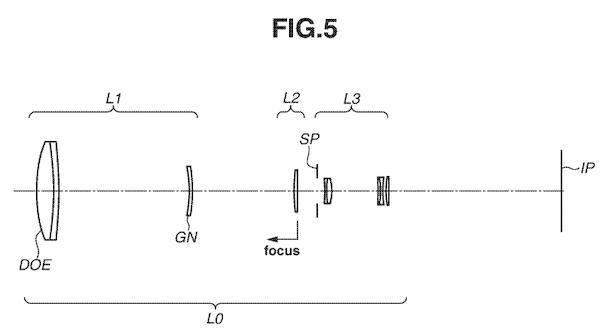

While I can’t find the lens block diagram, Canon has a fairly recent patent for 600mm and 800mm f/11 lenses that seems right. We know there are 10 elements in 7 groups in the 600mm f/11, (compared to 17 in 13 for a 600mm f/4 IS; or 18 in 12 for the 400mm f/4 IS DO lens). The patent is one element short of that, but patents often differ from the final product a bit.

I have to say, the DO element being right up there at the front makes me a bit nervous from a scratch and chip standpoint. But, the construction should be fairly simple in there. We think. Those of you who follow our teardowns know things are usually not like we think they’re going to be.

Let’s Take Stuff Apart

From the outside, it’s pretty much a standard looking lens, except for the ring that locks-unlocks to extend the barrel. You have to unlock, extend, and relock before the camera will let you shoot with the lens (shown here with barrel extended). Lots of air in there, we said. Easy disassembly, we said. It’ll be fun, we said.

Narrator’s voice: But it was not easy, and it was not fun.

Lensrentals.com, 2020

We removed the tripod mount first; a lot of telephoto lenses give you some access underneath the tripod mount.

Lensrentals.com, 2020

We found the mounting plate was quite a heavy, robust thing.

Lensrentals.com, 2020

But there wasn’t any access underneath it.

Lensrentals.com, 2020

The rear mount is pretty much standard.

Lensrentals.com, 2020

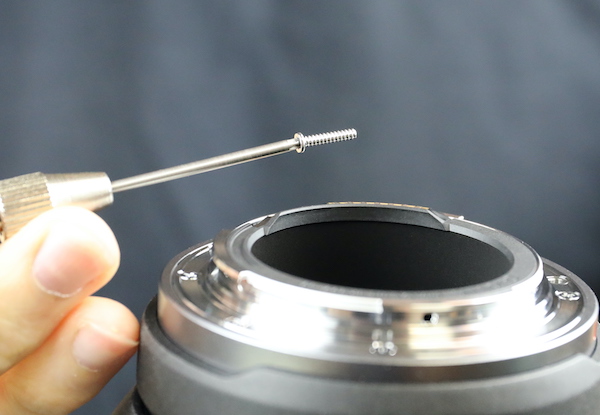

The bayonet is held in place by seven long, large screws. That’s more than most bayonet mounts, but the screws mount into plastic, not metal, so that seems like a good idea.

Lensrentals.com, 2020

Then we pop out the plastic light baffle. By the way, it says “made in Taiwan” on the inside of the baffle. I only throw this out because someone’s going to pop out their light baffle, read that, and then have a melt-down on the internet. It doesn’t matter where your lens is assembled; the parts inside it come from all over.

Lensrentals.com, 2020

Then we take off the bayonet.

Lensrentals.com, 2020

The spacer ring and rearmost barrel lift right off.

Lensrentals.com, 2020

Lensrentals.com, 2020

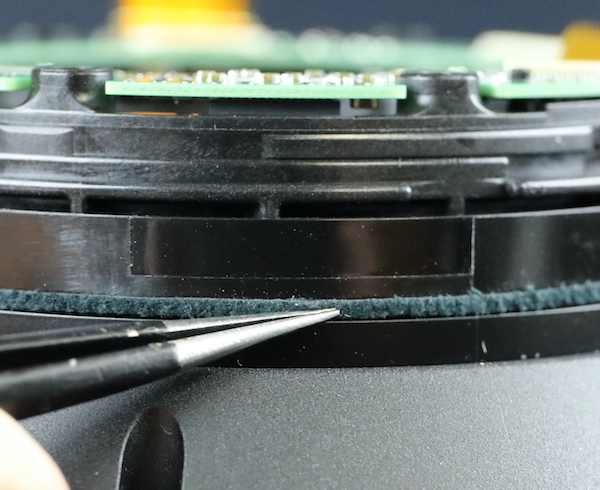

While this is not a weather-resistant lens, but there are some felt seals under various barrels, probably as friction pads.

Lensrentals.com, 2020

We took out the PCB and then removed the screws holding the ‘adjust-lock’ barrel in place.

Lensrentals.com, 2020

Which slides right off. This concludes the ‘just like we expected’ portion of this teardown.

Lensrentals.com, 2020

You can see the circular tensioning spring right above the felt in the image above; there’s also a standard spring on the opposite side of this barrel.

Lensrentals.com, 2020

There are a pair of extensive metal guides or posts that are involved in the locking/extension mechanism and probably provide some barrel support. We think. Honestly, we’ve never seen anything quite like this mechanism, so we’re hunting our way around here.

Lensrentals.com, 2020

It seemed the likely next move was to take those guides out.

Lensrentals.com, 2020

But they liked it where they were. Taking out the screws wasn’t quite enough to encourage them to leave their posts.

So we took out the ring of screws at the top of the extending barrel.

Lensrentals.com, 2020

That just let us slide the outer sleeve from the extending barrel.

Lensrentals.com, 2020

With that off, we have enough room to take out the metal side braces, or guides, or whatever you want to call them. They’re certainly more than the inch-long guides we were expecting.

Lensrentals.com, 2020

They’re quite solid pieces of metal, going almost the length of the lens, so I suspect the provide some structural rigidity.

Lensrentals.com, 2020

If you’re getting the impression that this doesn’t look like your typical Canon lens, well, so were we. Those long guides went way down into the lens. So do several flexes, and the flex layout is less direct than we usually see with Canon. Taking off the switch panel seemed like a good idea; it would hopefully let start tracing the flexes.

Lensrentals.com, 2020

But it really only showed us a plug for the switches.

Lensrentals.com, 2020

We took off the inside of the lock-unlock barrel and its circular spring next, mostly because we could see how to do it.

Lensrentals.com, 2020

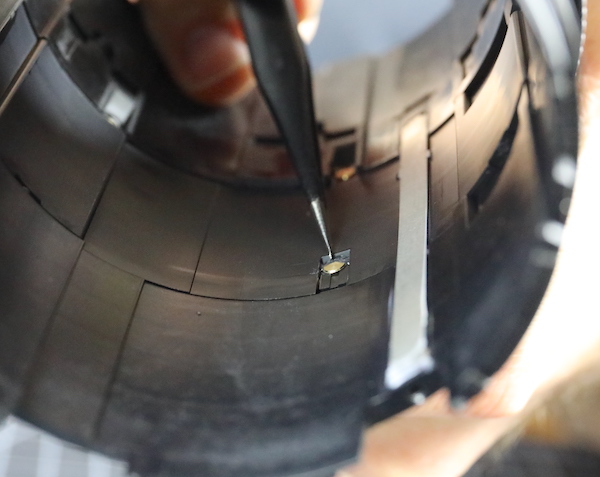

We can see the lock / unlock switch now. You can see the amber-colored plastic of a barrel guide in the upper left part of the image. There’s a pretty big flex with about 20 traces diving straight down into the lens. That many traces probably means it’s going to split like tree branches, so tracing it out is going to be ultra-important if we want this lens to work when we’re done.

Lensrentals.com, 2020

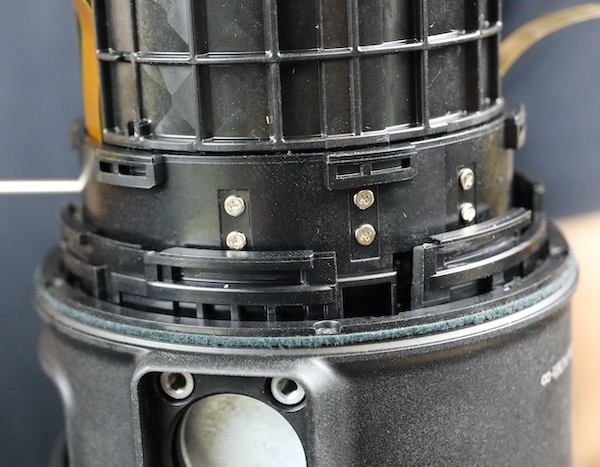

Now we can see the set of screws that are obviously holding the mid barrel, so those come out next, and the middle barrel should slide right off.

Lensrentals.com, 2020

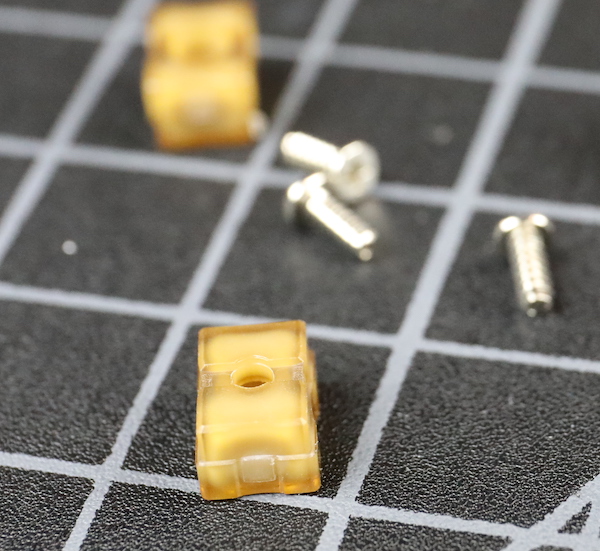

Well, the screws came right out, but the barrel went nowhere. We thought that taking out the set of guides (nice and sturdy, but a type of plastic we’ve not seen before) might help.

Lensrentals.com, 2020

Taking those out let us extend the barrel fully but did nothing else. It did expose a set of screws that looked like it held the extending barrel to the front barrel. The barrel-to-barrel junction is plastic to plastic, but numerous double screws hold it together, so it looks pretty sturdy.

Lensrentals.com, 2020

By the way, all the flexes are enthusiastically taped to the extending barrel. If you intend to enter this temple yourself, we suggest making heavy offerings of alcohol and heat to the Flex Gods, or you’re going to tear something you don’t want to tear.

Lensrentals.com, 2020

After taking out the junction screws, we offered up some 4-letter prayer words to the high priests of Canon engineering, because, well, nothing was coming apart, flexes dipped down into places we couldn’t reach, and everything was at a standstill. So we put the screws back in and decided we’d try going in from the front.

The makeup ring, like the flexes, took a fair amount of time to spungy off. Canon seems to have upped their adhesive game a notch. We weren’t playing anymore. After alcohol, we got out the heat gun and told the makeup ring, “you can come off, or you can melt; your choice.” The makeup ring decided this wasn’t the hill to die on and eventually gave way.

Lensrentals.com, 2020

With it out, we could remove a set of six screws underneath it.

Lensrentals.com, 2020

Which let us take off the filter ring. (Note: this means filter ring replacement is quick, simple, and probably cheap if you bust it.)

Lensrentals.com, 2020

Now we can see two sets of screws. The inner set seems to hold the front group in place, the outer set seems (I say seems because by this point we’ve lost trust in how anything seems) to hold on the focusing barrel.

Lensrentals.com, 2020

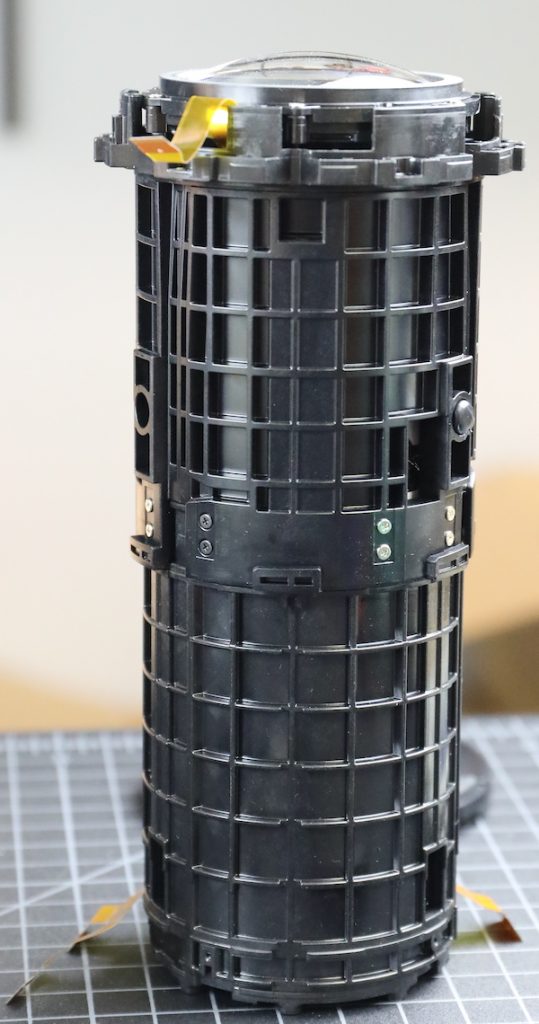

Taking those screws out let us finally accomplish something; the entire external barrel comes off as one piece. I wish we’d known this two hours ago.

Lensrentals.com, 2020

Lensrentals.com, 2020

A look inside shows us what was keeping the mid barrel from coming off and take the appropriate actions.

Lensrentals.com, 2020

Lensrentals.com, 2020

And that there are some internal posts that prevented disassembling the outer barrel piece-by-piece. So next time we’ll know, you have to remove the whole outer barrel before you start dismantling it.

Lensrentals.com, 2020

We also found that what looked like weird, random flex runs were because the flexes ran in an odd random way. They go all the way from the bayonet mount to the front of the lens, some of them turning around and going back down. It’s flex anarchy up in there. There’s probably some reason for it, but right now, 3 hours into an expected 1-hour disassembly, I think the reasoning took place after the engineers drank a lot of sake.

Lensrentals.com, 2020

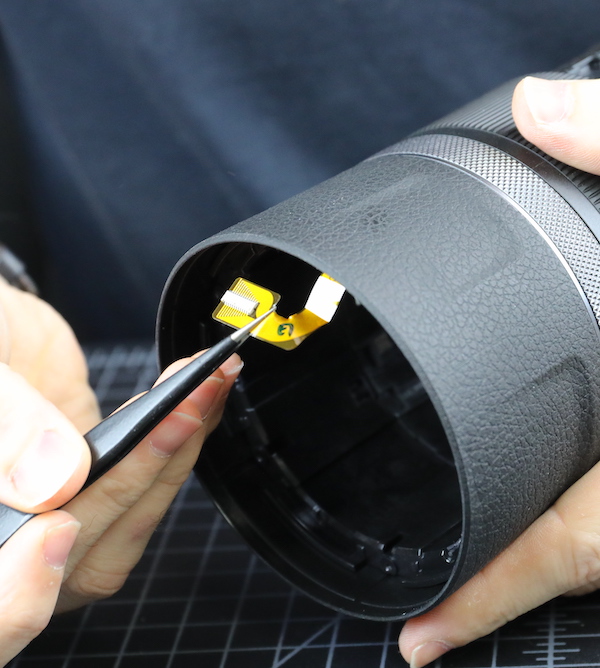

Below you see the SLAGI connector. As in “Seems Like A Good Idea” to run the flex all the way from the bayonet to the front of the lens, then connect it to another flex to run back down the lens.

Lensrentals.com, 2020

There are some very Nikon-like right-angle bends, tape holding stuff down, and even (GASP!!) a bit of flex solder. That 20-something trace flex split into about half-dozen different traces that took about three right-angle turns each.

Lensrentals.com, 2020

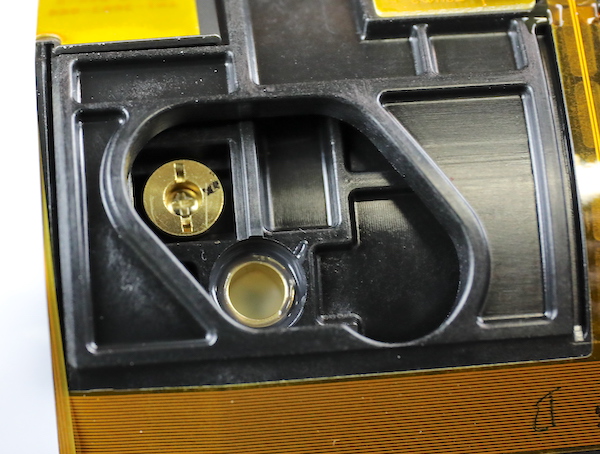

While the electronics don’t look like the usual Canon lens, the optics do. We can also see there are several robust eccentric adjustment colors on some of the mid-area lens groups. You can see one to the right of the white tape above; there’s another shown down below.

Lensrentals.com, 2020

And yet another paired set towards the rear.

Lensrentals.com, 2020

With all this disassembled, we went back and finally took out the screws that seemed to hold the extending barrel in place and took them out.

Lensrentals.com, 2020

And then could slide it off.

Lensrentals.com, 2020

We can look down and see the IS unit now, still reasonably far forward in the barrel.

Lensrentals.com, 2020

We examined the screws holding the front element in place; it’s neither shimmed for tilt, nor a centering adjustment (full disclosure: we have no desire to try centering a DO element), so we took those out.

Lensrentals.com, 2020

This just removed a ring plate holding the front element down.

Lensrentals.com, 2020

You can see the front group is a cemented pair now, just like the patent diagram suggests. If you look into the slots below the element, you can see (OK, we could see) that it was cemented in place. We had zero interest in breaking up that cement just to look down the barrel.

Lensrentals.com, 2020

That’s All Folks

At this point, we were over 3 hours into disassembling this beast, and I had to leave in another hour or two. The front group was cemented in place; we weren’t going to uncement it. Further barrel disassembly was going to start with a LOT of flex tracing and unhooking, and we just weren’t up for that today.

We’d found the electronic construction was complex for a Canon lens, or at least very different. The optical construction in the core has a very Canon look, with numerous optical adjustments/compensations using their new, large eccentric collars. I remain convinced this is because Canon is making automated optical adjustment of subgroups during assembly. Nobody else is adjusting to this degree or in this manner.

So Aaron put the lens back together, and I went off to vacation and to take some pictures to see if it reached my ‘acceptable for internet’ level of low expectations. Except, as I so clearly foreshadowed, the damn lens didn’t work. During reassembly, we buggered up the ‘barrel extended’ switch so the camera wouldn’t recognize the lens was ready to shoot.

Pride goeth before the fall, as they say. For the first time in our long history, we didn’t test the lens after reassembly, because ‘we got this.’ So a week later, Aaron’s going to have to take this lens apart again so we can figure out what we buggered up.

So we got an AFLE on this one; Another Frigging Learning Experience. And what did we learn? That we don’t want to work on the Canon RF 600mm f/11 IS STM. Life’s too short. When these break, they’re going to the Canon service center. Except for this one, cause those Canon techs would enjoy fixing what we broke far too much; we’re never going to tell them this happened.

Roger Cicala and Aaron Closz

Lensrentals.com

August, 2020

Addendum: Just to avoid having to answer 4 times in the comments; Aaron did fix the lens, turns out this switch had to be put one way during reassembly, and we put it the other.

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Traveler

-

Olandese Volante

-

Andrew Leonard

-

Andrew Leonard

-

Jan Steinman

-

Urbex Mark

-

A Canuck

-

Roger Cicala

-

Freejay

-

Spamspam Gringo

-

Chik Sum

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Olandese Volante

-

DrJon

-

Olandese Volante

-

DrJon

-

Henry Winokur

-

Henry Winokur

-

Olandese Volante

-

Olandese Volante

-

GulliNL

-

Olandese Volante

-

Olandese Volante

-

GulliNL