New Items

The Secret of the Broken Element: A Canon RF 100-500mm f4.7-7.1 Teardown

Image courtesy Joey Miller.

In ancient times, the IS unit in Canon EF lenses was physically locked down, so the unit didn’t make rattling noises when the lens wasn’t powered up. Canon decided the lockdown was no longer necessary in modern times, so some RF lenses, like the Canon RF 100-500mm f/4.5-7.1, rattled when the lens wasn’t mounted to the camera. And the people heard the noise and were sore afraid. And they worried about this on interweb forums and such.

Me being me, I said, that’s silly, it will be fine, don’t worry. So, of course, something bad happened. We had several of these lenses come back from rental with a cracked internal element. In every case, it seemed to have happened during shipping. If you’ve ever rented from us, you know how we pack. Nothing should break in shipping. And so, we were sore afraid.

Lensrentals.com, 2021

In every case, when we looked through the lens, the crack moved when we shook the lens. So, I assumed the cracks were in the IS unit since it moves when you shake the lens. As usually happens when I assume, I was wrong. But it took a complete teardown (and I do mean complete) to figure that out.

So, Junior Tear Down Scouts, grab your screwdriver and follow along as we tear down our 100-500 lenses!!! (Editor’s note: No, do not do that. Roger’s being ironic because he thinks it’s amusing.)

The Easy Stuff First

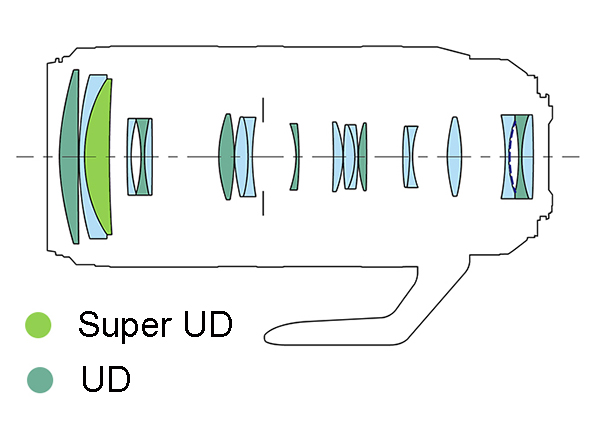

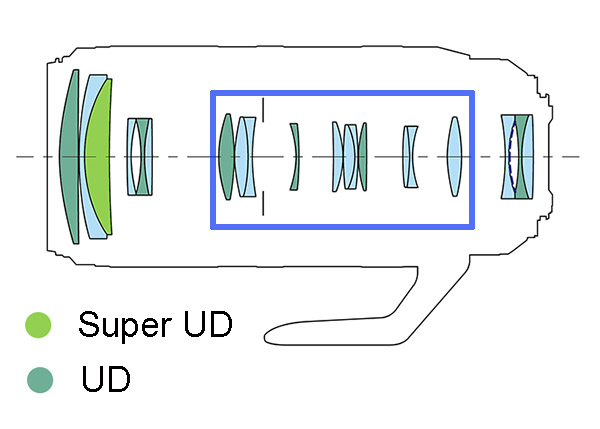

All we know about the inside of this lens is from an online lens diagram. There are eight groups with 20 elements. We think the second group from the front is the IS group.

Image from Canon USA.

So we thought we’d start disassembly from the front.

Lensrentals.com 2021

The filter barrel comes off after removing a few screws—good news for those of you who break filter barrels or lens hood tabs. There’s a nice thick ring of sealing felt underneath there, too.

Lensrentals.com 2021

There’s an impressive nine screws around the front group.

Lensrentals.com 2021

But three of them hold on to a weather sealing ring. This had the foam we showed you before, and the undersurface was coated in sticky adhesive as a secondary dust trap.

Lensrentals.com 2021

The other six screws were there to hold the front group in place; there were no adjusting shims for tilt, and no centering mechanism in the front element, so it’s easy to remove.

Lensrentals.com 2021

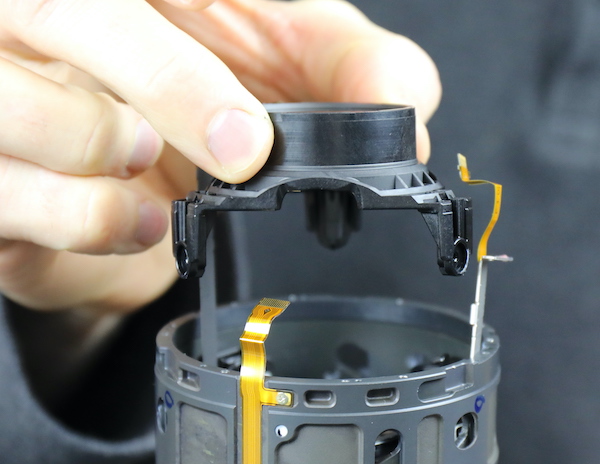

For those of you following along with the lens diagram above, this first group has three elements.

Lensrentals.com 2021

Now we can look down at the front of the IS group, where we had thought our crack was. Without the front element bending light rays, the crack moves less when we shake it, although it still appears to move. So we’re not sure if it’s the rearmost element in the IS group or not in the IS unit at all. In other words, we’re now a little confused.

Lensrentals.com 2021

There was no apparent way to remove that light baffle, and taking the zoom rubber off showed a LOT of cams and screws, some of which were adjusting collars. Since we weren’t sure what was connected to what, and there was no obvious way to take the zoom barrel off, we left well enough alone.

Lensrentals.com 2021

Like the cowards we are, we fled around to the back of the lens, where we knew how to take stuff apart. The usual rear removal: screws out, baffle out, bayonet off, weather seal off.

Lensrentals.com, 2021

Lensrentals.com, 2021

Lensrentals.com, 2021

There’s a spacer that lifts off next. As best we could tell, this is not sized, so it’s not acting as a variable optical spacer. (Canon sometimes uses variable-sized spacers instead of shims. This lens had neither.)

Lensrentals.com, 2021

Then we disconnect a bunch of flexes and remove the PCB.

Lensrentals.com, 2021

Which exposes all the screws holding the back lens barrels in place.

Lensrentals.com, 2021

The programmable barrel comes off first; you can see the optical markings on the inside.

Lensrentals.com, 2021

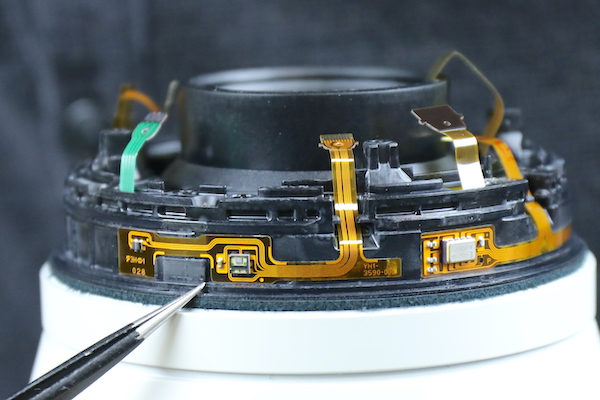

Underneath are the optical sensors (near the forceps) that tell the camera that the barrel is being rotated. To the right is one of the IS sensors.

Lensrentals.com, 2021

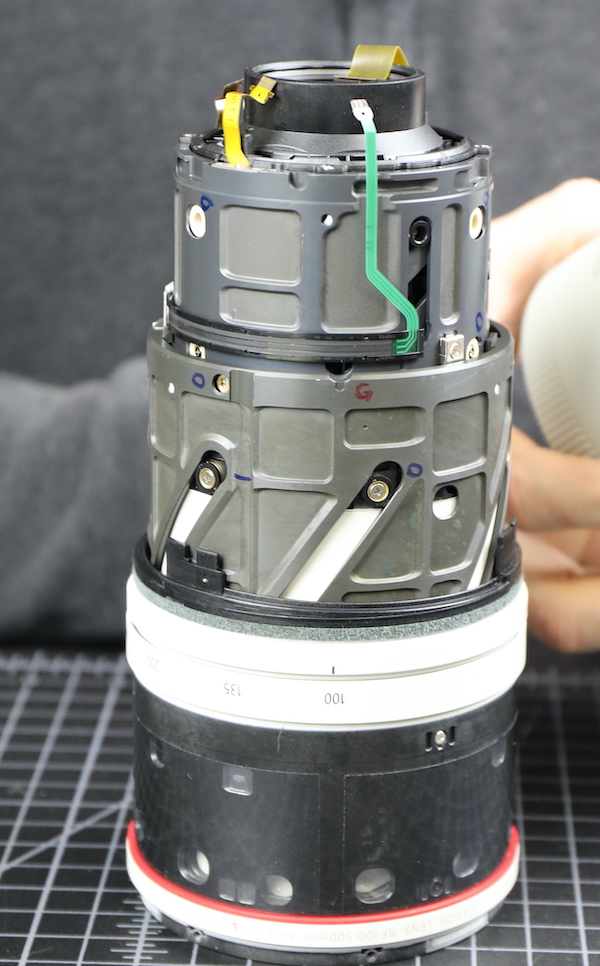

Removing a set of 6 screws let us slide off the entire rear barrel, which was a wonderful thing.

Lensrentals.com, 2021

Remember all those flexes going into the PCB? With some brands, we have to trace out and disconnect each of them individually. With this modular construction, most of them are contained within this barrel and just slide right off. I get accused every so often of being a Canon fanboy (or Sony, or Sigma, etc.). I’m not, but I’ll readily admit I’m a Canon lens construction fan; these are a pleasure to work on compared to most brands.

Lensrentals.com 2021

The smooth tighten ring slides right off. Every external barrel joint has a ton of thick sealing/friction foam, which is what we expect to see from a lens in this price range.

Lensrentals.com, 2021

Underneath the barrel, we start to get a look at how the optical elements move around.

Lensrentals.com, 2021

And it quickly became apparent that just about everything moves in an impressively complex fashion.

Lensrentals.com, 2021

A couple of things are worth noting. The front barrel moves along six (as opposed to three in many extending barrel zooms) heavy-duty rollers with some added straight sliding cams (not visible in images), preventing barrel sag. The rear group moves forward into the barrel at full extension, but it’s a separate movement distance, it’s not just dragging along for the ride with the extending barrel.

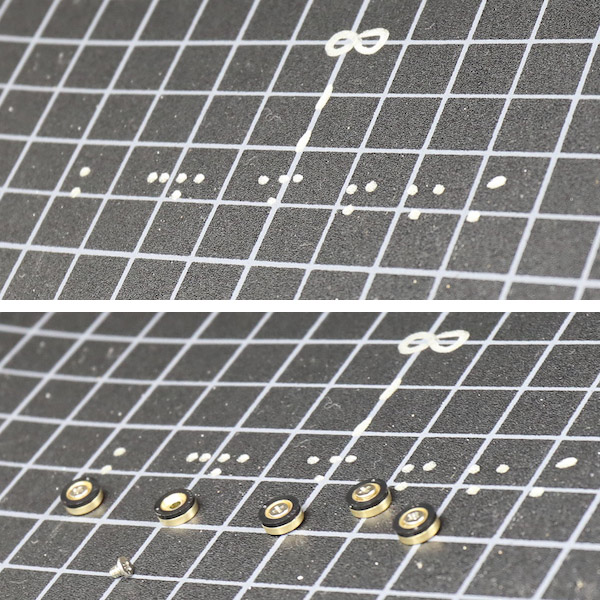

A closeup of those extending barrel rollers: heavy screw through heavy brass bearing with a thick nylon roller. When we took them out we found they were sized, so that each has no play but still moves smoothly. But that also means we had to keep track of which bearing went in which slot when we took them out. You don’t have to be OCD to take lenses apart, but . . . oh, wait, yeah you do have to be OCD to take lenses apart.

Lensrentals.com, 2021

This is why nice things cost more; a lesser lens has three same-size small nylon bushings over screws. Here’s a close-up of one of those bearings.

Lensrentals.com, 2021

Go have a cup of coffee now while Aaron takes out and marks the positions of a half dozen rollers, three guide bars, and another half dozen assorted screws. After he takes those out we can remove the zoom barrel.

Lensrentals.com, 2021

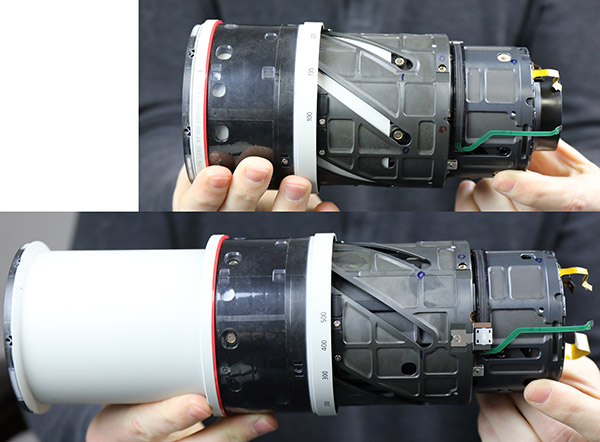

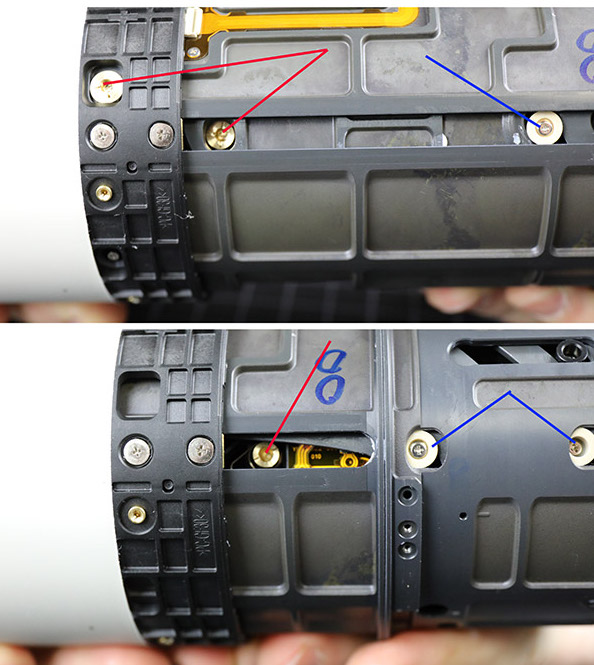

We can move around the zoom and focusing barrels, letting us look at deeper sets of roller bearings (blue lines) and adjustable eccentric collars (red lines). Everything is oversized and robust.

Lensrentals.com, 2021

Removing a few more screws lets us take off the extending barrel.

Lensrentals.com, 2021

Now for the Harder Part

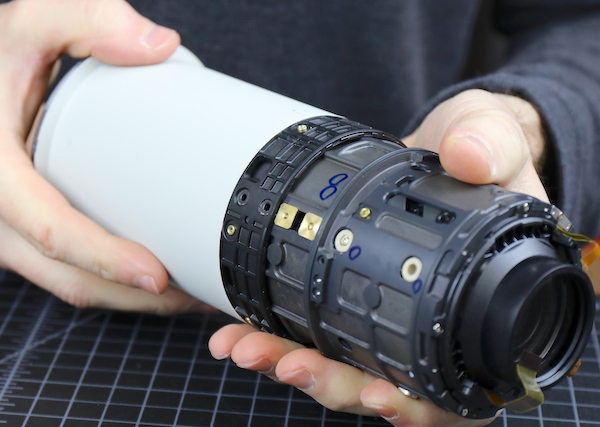

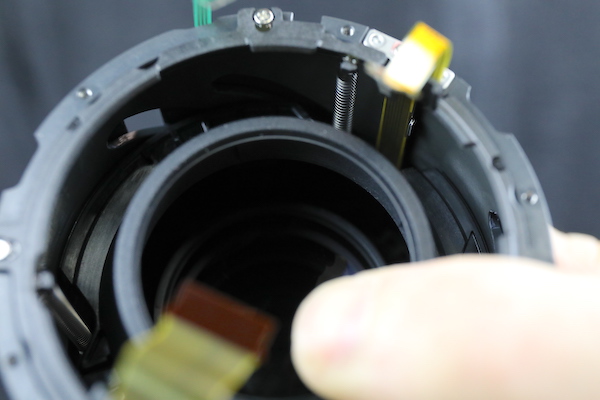

Time-wise, we’re about halfway done; we’re down to the inner barrel which contains all of the optics excluding the front element that we took out an hour ago. The IS unit flex is running up to the IS unit.

Lensrentals.com, 2021

With the barrel off we can get a clearer look at the IS unit, but still aren’t certain if the crack is in one of the rearmost elements of the IS group or somewhere behind it. It still seems to move when the IS unit moves.

Lensrentals.com, 2021

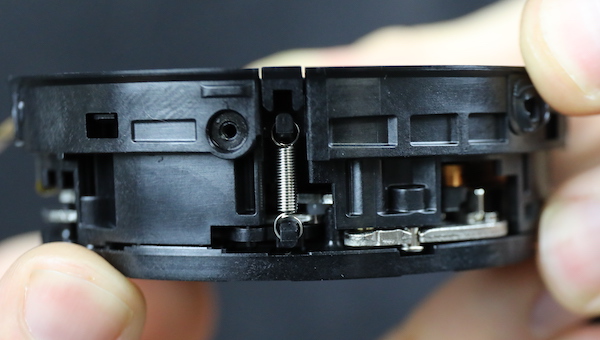

Near the rear element is an interesting thing we haven’t seen before. The rear baffle is suspended on three springs, letting it move with a little give as the rear element moves. I think that’s the purpose, at least. We’ve noticed more and more tensioning springs in Canon lenses the last few years, which suggests they originally thought it was a good idea, found out they were correct and increased usage. This lens has over a dozen springs.

Lensrentals.com, 2021

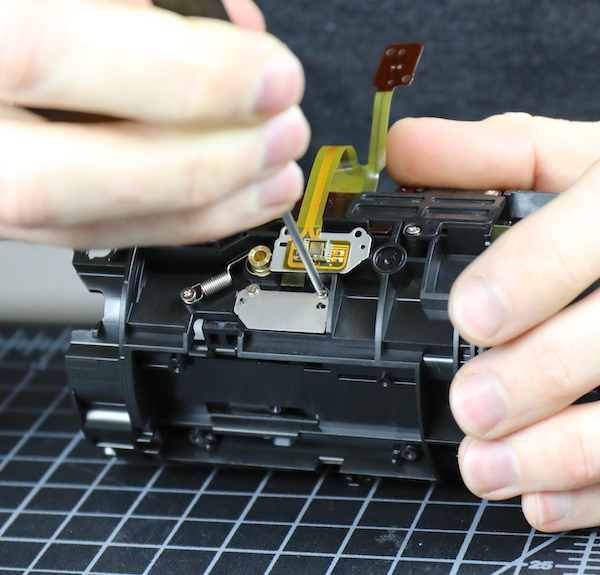

The IS unit has optical adjustments, so those have to be marked for position, then we can remove the fixed screws and adjustment collars.

Lensrentals.com, 2021

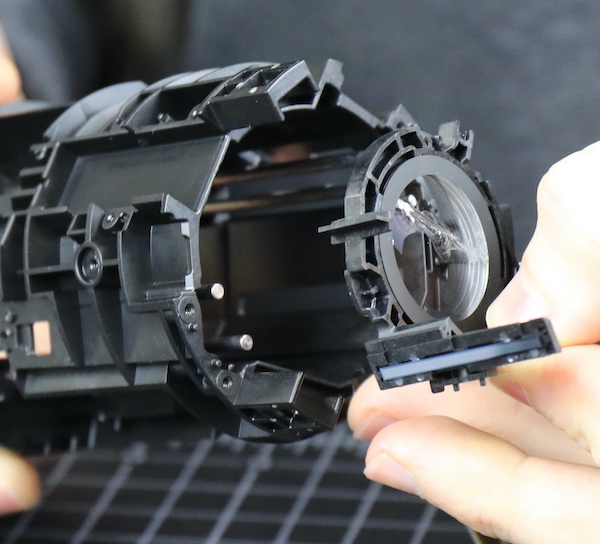

Once out, it’s apparent the IS unit is not the location of the broken glass. It’s apparent this is a pretty robust unit. Optically it’s pretty strong; you can get an idea in the image below, looking through the glass at the gridlines on the table. That is why the crack behind it appeared to move when the IS unit moved.

Lensrentals.com, 2021

In older lenses, we sometimes saw IS units that were encased in a ‘cage’ of plastic bars, which broke sometimes. This is not that at all, it’s heavy-duty interlocking plastic shells with multiple screws and tension springs. We could (OK, we did) shake the heck out of it. It just rattled a bit, but there was nothing but solidness here.

Lensrentals.com, 2021

Looking through the lens now, we could see the broken element was not right behind the IS unit, it was further down, so more disassembly was needed. The rear group seemed pretty accessible so we went there next.

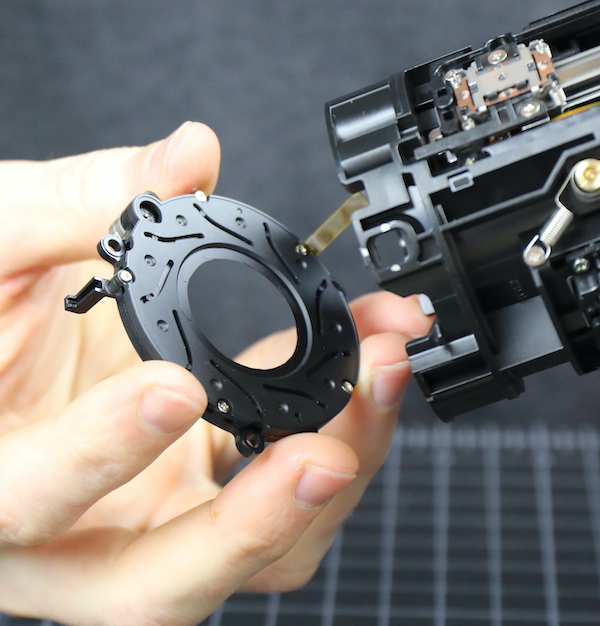

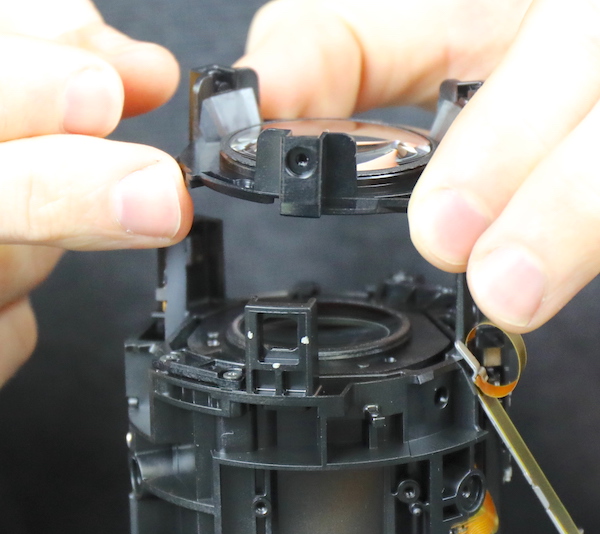

Removing a few screws let us take out the spring-loaded baffle assembly. It’s a complex little bit of engineering for a baffle.

Lensrentals.com, 2021

With that out of the way, the rear element can be removed.

Lensrentals.com, 2021

After this, there don’t seem to be any more elements volunteering to leave the barrel singly, they’re all nested in there together. It might be worth revisiting the lens diagram now; at least that’s what we did. We’ve removed the front group, IS unit, and rear element. I’ve drawn a blue box around what’s left in the barrel.

Lensrentals.com, 2021

So, go have another cup of coffee (I did) while Aaron spends 20 minutes marking and removing screws, cams, rollers, and sliders. All of which were heavy-duty robust things as we would expect them to be in a lens like this.

Lensrentals.com, 2021

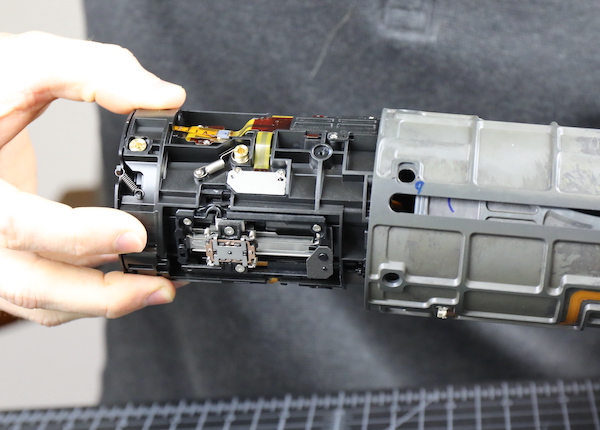

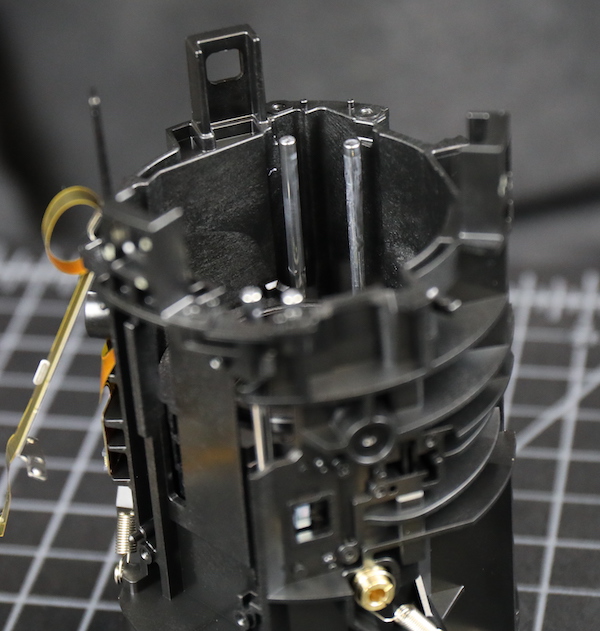

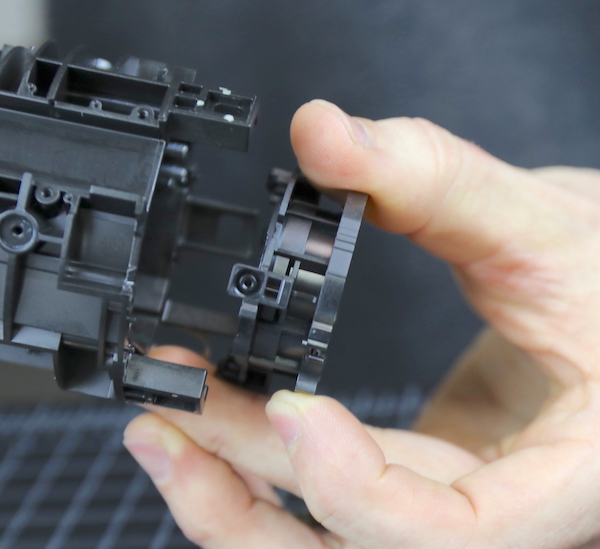

After which, the Inner Barrel of All the Good Stuff comes sliding out of the cam barrel. We still haven’t removed any glass, just taken off another layer of mechanics.

Lensrentals.com, 2021

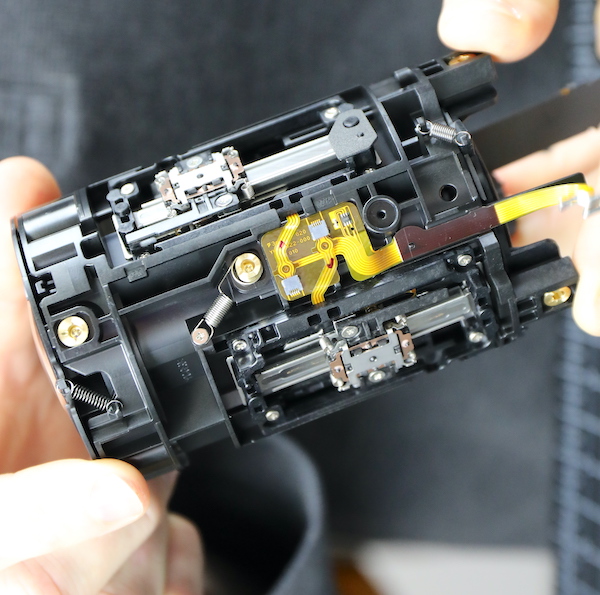

This inner area is an impressive and intense piece of engineering. You can see the two linear focusing motors (notice they are at different levels, because each drives a different element), along with adjustable collars, various flexes, and lots more tensioning springs. I told you Canon was liking them some springs these days.

Lensrentals.com, 2021

The cracked element is obviously within this assembly but we still can’t be certain which element it is, other than it’s neither the frontmost nor the rearmost.

Lensrentals.com, 2021

I suspect that this entire assembly is a single part in the part catalog; that the repair center just replaces it as one piece if anything breaks in there. But we want to know what broke and perhaps find out why it broke, so we’re going to take this a bit further than the usual disassembly.

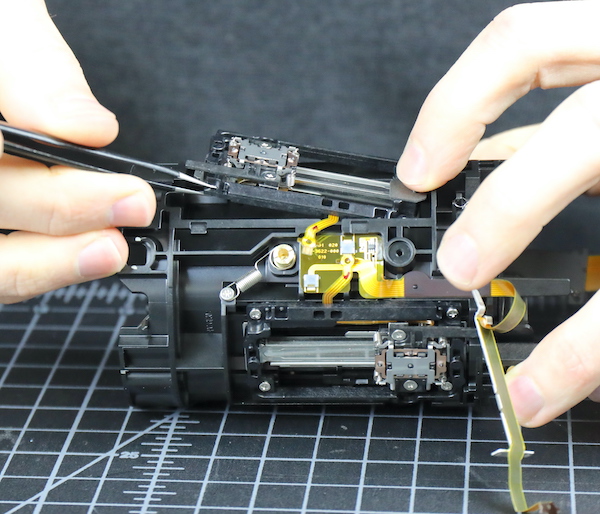

So Aaron started marking adjustable collars to remove the foremost group, the one in front of the aperture assembly.

Lensrentals.com, 2021

This comes out easily enough. As the lens diagram above shows, it’s a fairly thick group containing three elements.

Lensrentals.com, 2021

Finally, we can see that the cracked element is the one right behind the aperture assembly. That’s a thin singlet that we can tell by moving the front focusing motor manually is also the forward focusing element. (It may be a close focus compensating element, I don’t know. Hopefully one of the lens designers will let us know in the comments.)

Lensrentals.com, 2021

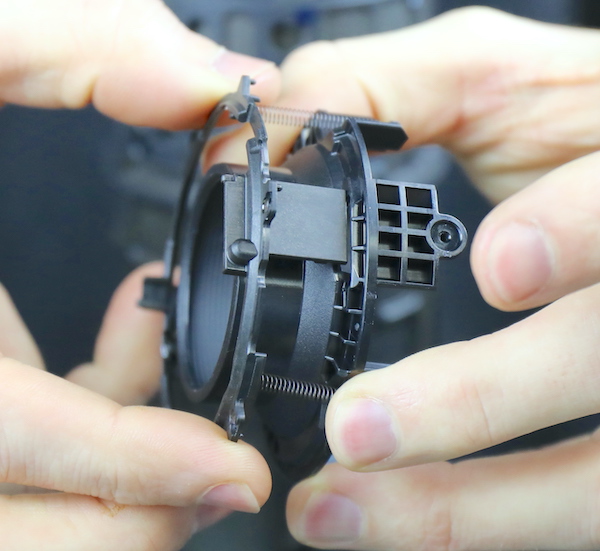

There’s no possibility that this element could physically contact the one we just removed. The aperture assembly separates them and the aperture is soft and flexible, so that couldn’t have caused damage. We decided we should open up the AF assembly and see what could have happened in there.

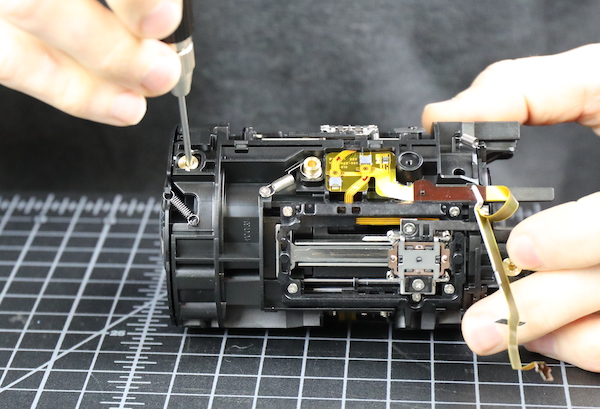

So off comes the aperture assembly,

Lensrentals.com, 2021

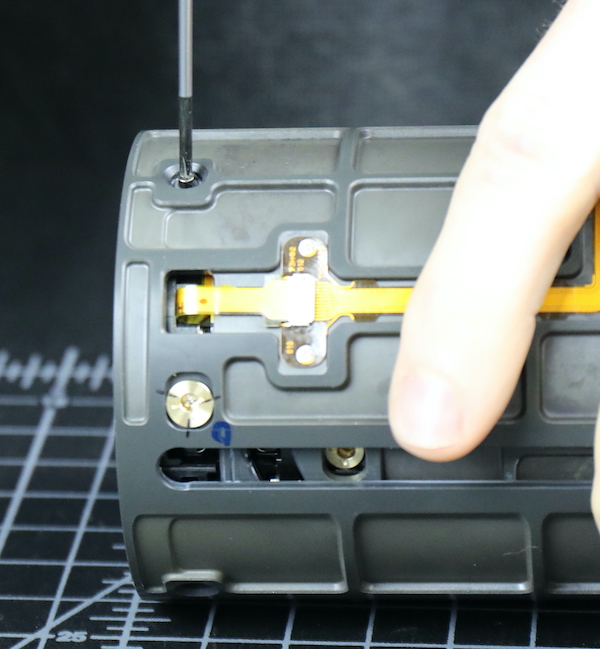

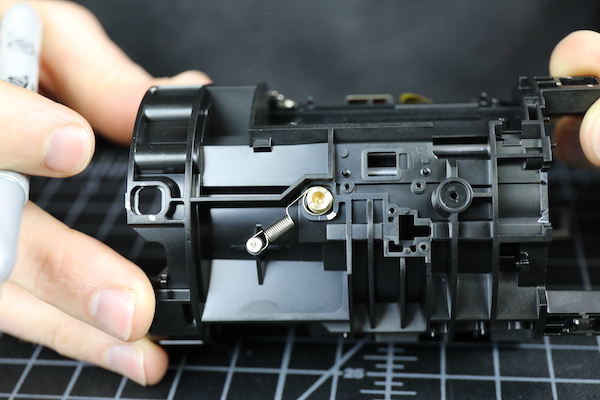

the linear focusing motors,

Lensrentals.com, 2021

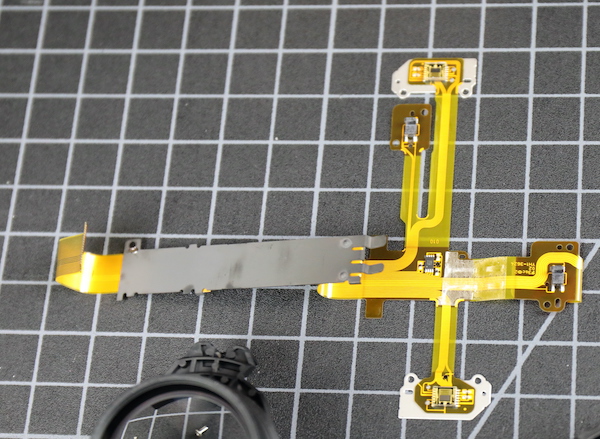

and the complicated set of flexes that contain the focusing position sensors.

Lensrentals.com, 2021

Lensrentals.com, 2021

The rest of the elements are removed through the back. Removing a few screws and cams let us take out the large biconvex singlet.

Lensrentals.com, 2021

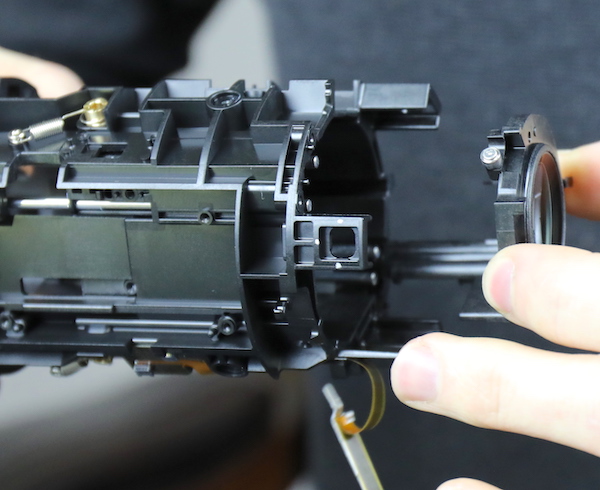

Next, some back caps have to be removed to expose the rods (there are two sets of two rods) that the focusing elements slide on.

Lensrentals.com, 2021

Then the rear focusing group can be removed after it’s detached from the rear focusing motor.

Lensrentals.com, 2021

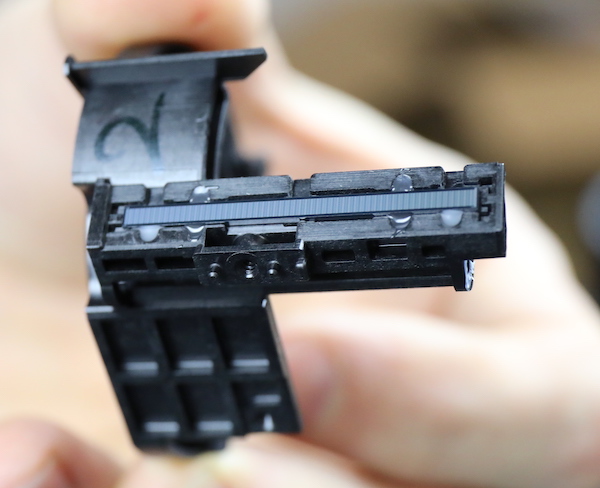

You can see the positioning sensor strip that is read by the sensors on that flex we just removed.

Lensrentals.com, 2021

There are still some adjustment collars, springs, and cams to take out that hold the center group in place.

Lensrentals.com, 2021

This is another chunky group containing four elements.

Lensrentals.com, 2021

There is no indication that the cracked element ever impacted here; the glass and surrounding mount have no impact marks. We later measured things and it’s physically impossible for the focusing element to impact this group.

Lensrentals.com, 2021

After that, the forward focusing element, the one that is cracked, can now be disconnected from its motor and removed. Again, the element was properly attached to its motor and sliding bars. Experimenting made it clear that there was no way the element could impact anything inside the barrel.

Lensrentals.com, 2021

No question this is the cracked element. Roger’s Rule of Broken Parts: the hardest to get to part is the one that’s broken.

Lensrentals.com, 2021

Lensrentals.com, 2021

So What Did We Learn Today?

Well, for the 116th time, I learned don’t make assumptions. For the 243rd time, I learned that a lens is full of elements that refract images so looking through either end into the middle is a fool’s errand. Why do some lenses have lots of dust inside? Mostly because some front elements magnify dust. Why did this crack seem to move with the IS unit? Because the IS unit refracted the image of the crack and made it seem to move with the IS unit.

We also learned that the crack occurred in the front focusing group, a fairly thin, singlet. I’m no materials physicist, but I think thin elements are more likely to crack than thick ones. But there I go, assuming again. We did carefully check the movement of each element in the inner barrel with the focus motors off, etc. and there is no possibility this element impacts any other element. There doesn’t seem to be any hard stop in its travel that could cause a shock with movement.

So why did several of these crack during shipping? I have no idea. My first thought, given that it’s winter, was perhaps temperature shock, moving from sub-zero trucks to warm indoors or something. But I’ve asked several people more knowledgeable than I and none think that’s a possibility. The ones that cracked are all early copies from a similar serial number range, perhaps there were some flawed elements early on.

Maybe it’s just a statistical anomaly; we have a lot of copies and stuff happens. Or maybe it’s something we do or something with shipping. Nobody else has reported this. It’s worth looking into further, there are a number of things we’ve noticed before anyone else just because we have a lot of gear and a lot of repairs and inspections. But it may be an oddity that never happens again.

In any case, we’ve forwarded all of our data and broken lenses to Canon. Canon is always proactive about investigating these things and one of the few companies willing to publicly say when they actually have a problem. They have assigned a team to look into it, we’ve already given them some more information they’ve requested, and they’ll figure out if there’s a problem or not.

The rest of the teardown is what we expect from an RF L series lens. It’s filled with very robust construction, neatly and clearly laid out in a modular manner. It’s a very well-built and sturdy lens with cutting edge technology. It will be very easy to do simple repairs like filter barrel and front element replacement. It will probably be expensive to do major repairs if I’m right and that central barrel is a single part.

Roger Cicala and Aaron Closz

Lensrentals.com

January, 2021

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Axi Om

-

Michael Clark

-

rocketride

-

rocketride

-

rocketride

-

rocketride

-

Chik Sum

-

Simon Packer

-

Ernest Green

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Nim

-

Stanislaw Zolczynski

-

Joey Miller

-

Guntram Lampert

-

GunPatent.com

-

Roger Cicala

-

Francis Placido

-

Olandese Volante

-

Athanasius Kirchner

-

Dave

-

Olandese Volante

-

Chik Sum

-

Andreas Werle

-

JB

-

Athanasius Kirchner

-

Rob Hompe

-

James Tappin

-

Lawrence Lee Huber