Geek Articles

Still Tearing It Up: Teardown of the Sony PTZ FR7

A Birthday Teardown

Let’s talk about the Pink Elephant in the room and get that out of the way. I ghosted you, I know. It wasn’t my plan, but sometimes shirt happens. Kind of a perfect storm of shirts, actually. There was Covid when everything came to a halt, and we wondered for most of a year if the business would stay viable.

Then my vision started going all to hell. Like many have said, if I knew I was going to live this long, I’d have taken better care of myself. Cataract surgery, complications, more surgeries, and a lot of time where I could see out of, at most, one eye.

At the same time, Lensrentals outgrew its space for the 13th time. That meant renovating a huge building, installing 4 miles of computerized conveyor systems, 62 workstations, and a 10,000-square-foot vault to hold 50,000 items, among other things.

While not working much was frustrating at first, well, with some practice, I’ve gotten really good at it. I’m honestly enjoying not working more than I would have expected.

However, while I may no longer be blogging teardowns, at Lensrentals, they’re still taking things apart every day. The idea was brought up that Aaron and I should do a teardown for Lensrental’s birthday celebration. I can see well enough to do what I’ve always done during teardowns: watch Aaron work while making helpful comments like “I wonder what that is” and “we probably should have gone in the other way”.

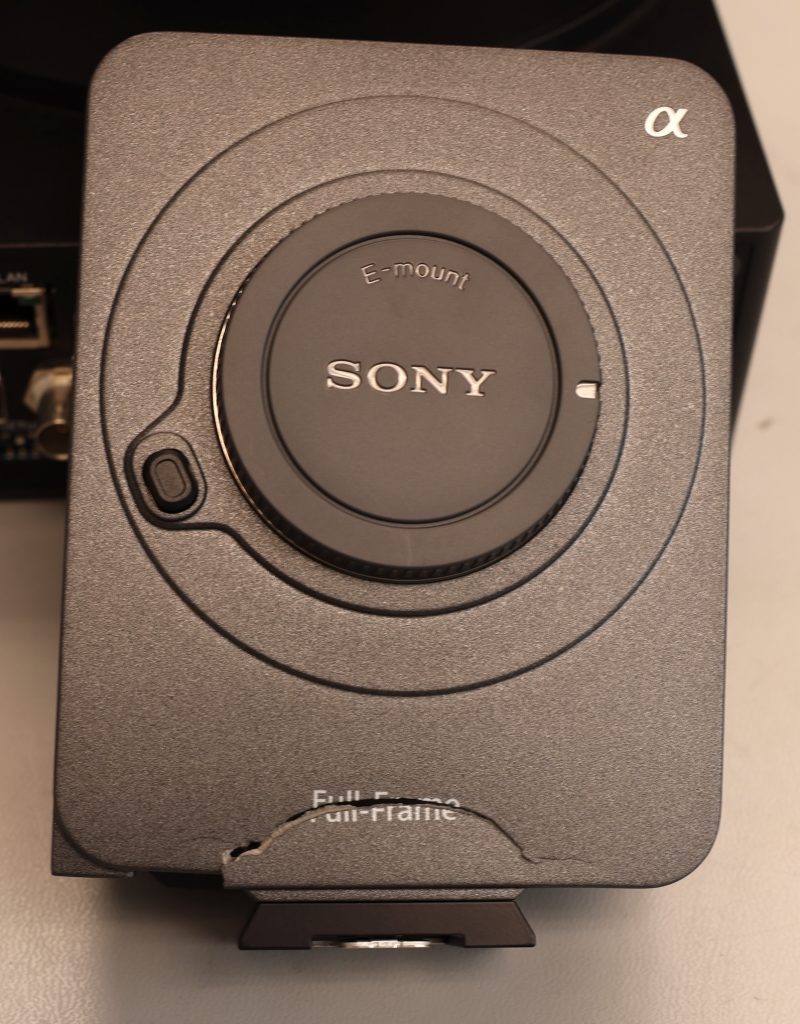

Today’s Victim

Most of our teardowns are done for a purpose, and this is no exception. Sony PTZ cameras are extremely popular rentals right now; they offer some amazing capabilities at a price that makes people think, “Maybe we should just rent that when we need it”. However, it has been a bit of a problem for us in terms of repair, as it breaks fairly often.

The camera we’re taking apart today has two of the more common and minor problems. First, the tilt-shift gears are sticky and making grinding noises. Second, there’s a looseness where the camera mounts into the tilt shift gimbal on one side. We already know how to fix both of those, but since these are common and fairly straightforward fixes, we figured we’d show them to you.

This camera does not have the more devastating, although less frequent, problem we see. (I say it’s the most devastating because the factory repair cost is a breathtaking $6,000; they basically just replace the camera.) The problem is basically the camera body breaking at the mount.

Obviously, this can happen during use, but our biggest concern is that it has also happened during shipping. Shipping damage is a pretty rare thing for us; if you’ve seen how we pack equipment, you understand why. We have an entire department that designs and manufactures custom packaging for our items, and then tests the packaging. The 5-foot drop test is a real thing for us.

So we’ll disassemble the camera body today too, hoping to find a way to prevent that fracture.

Let’s Take Stuff Apart Then

So come on and join us at the Group W Bench in Room 212 here at Lensrentals HQ and let’s get to work.

The first step is pretty obvious: taking the camera off the PTZ mount. The rod lock in front is removed by taking out a couple of screws.

There’s also a camera stop that needs to be removed.

Then you can slide the camera off the rail. You don’t want to tug on that cord very hard, while it’s firmly anchored, the cord itself is an $800 part. Don’t ask how we know that.

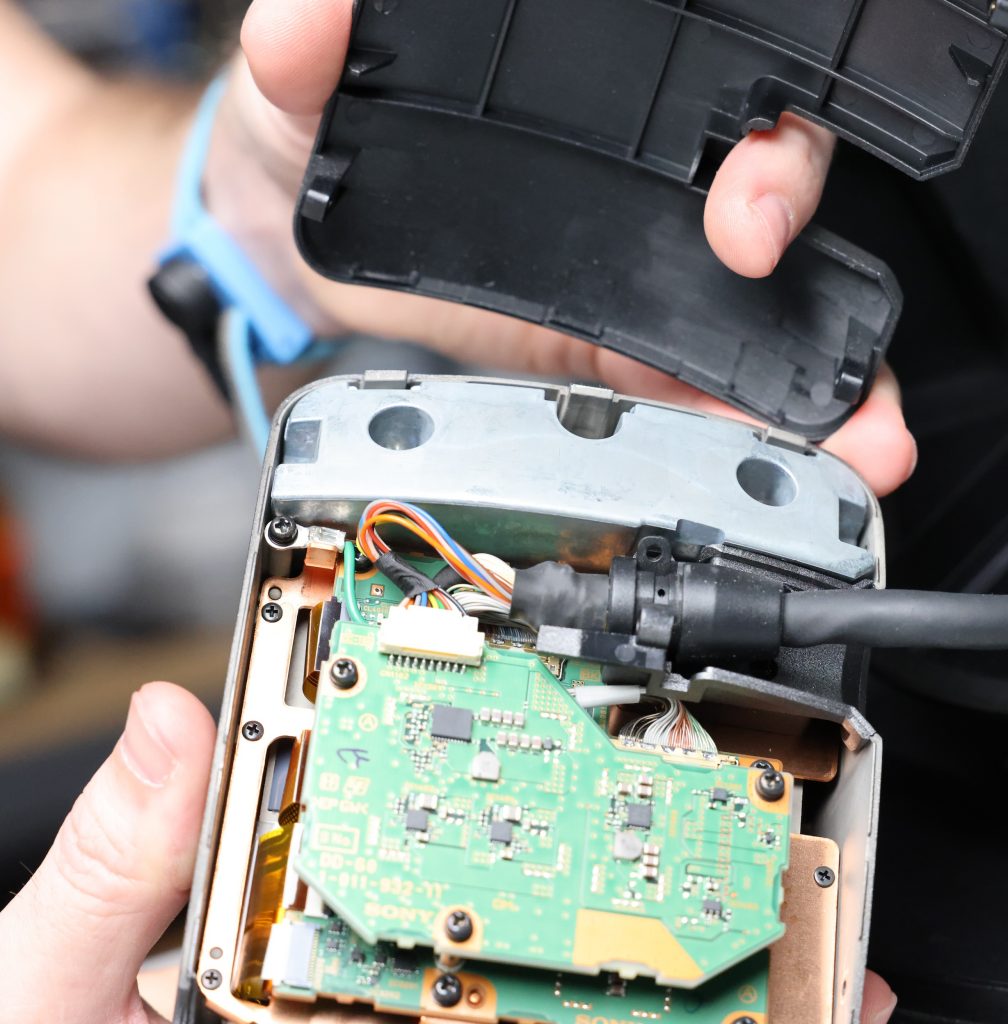

Since our first order of business is to examine the camera case to determine why it breaks at the base, we’ll open it up by removing the screws holding the back in place. We use a proprietary device (Aaron’s left hand) to keep the camera in place so we don’t tug on the cord much while doing it. I guess I could have held it for him, but my hands were occupied by a camera and a coffee cup.

You also need to remove the small makeup plate at the bottom. For those of you doing your own disassembly at home, there is the traditional, somewhat hidden, screw that you find when the back doesn’t come off after you’ve thought you’ve removed all the screws.

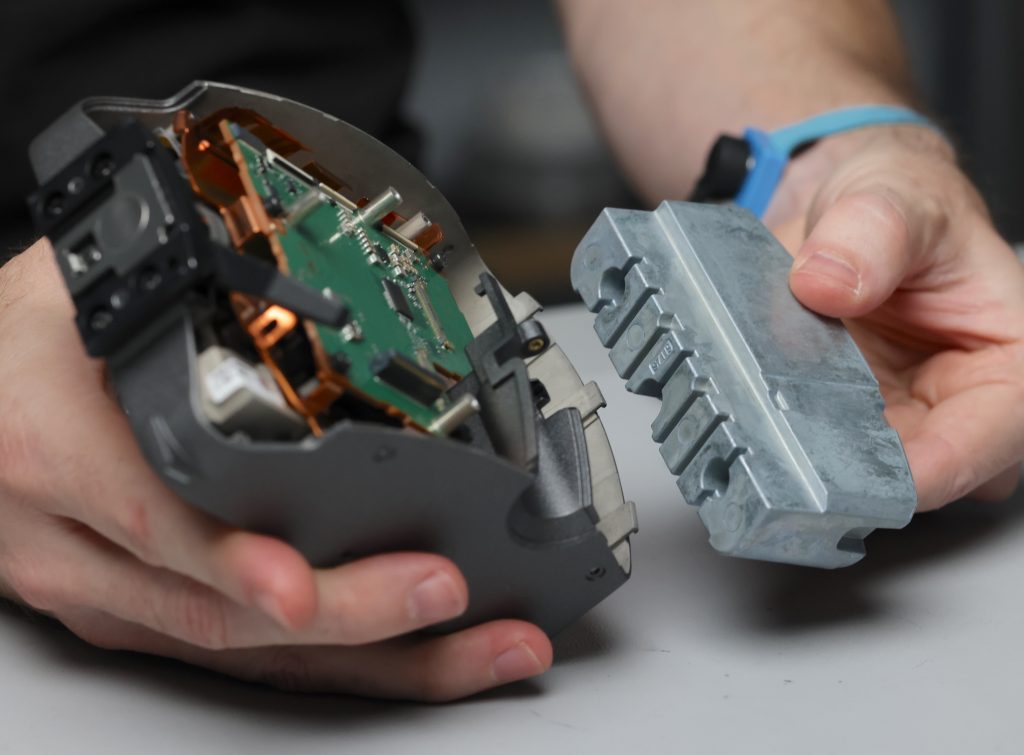

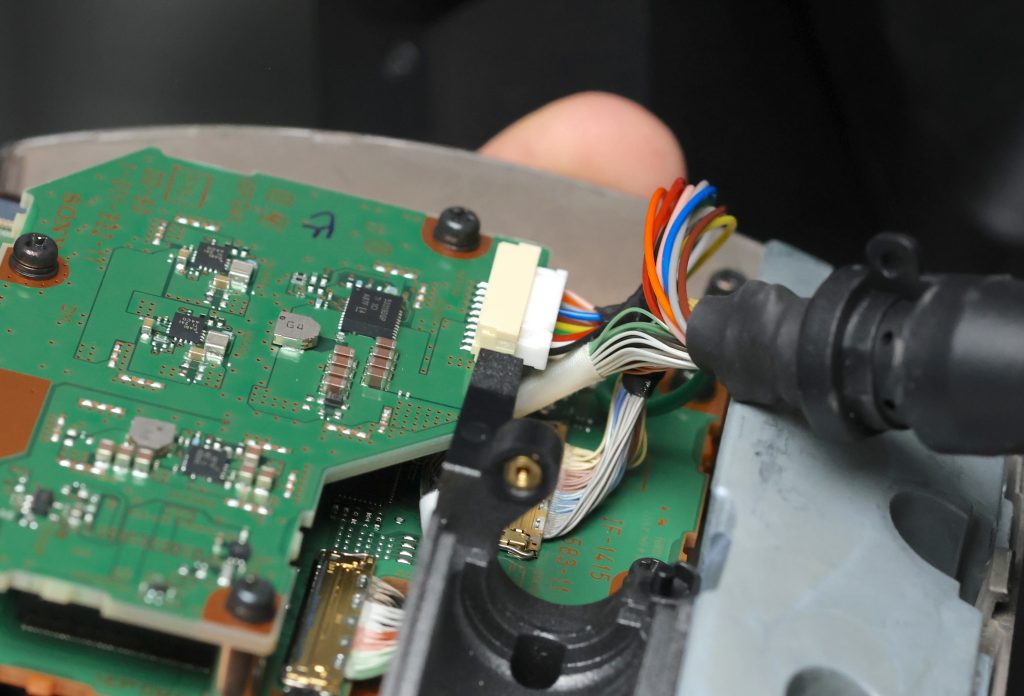

Now the back comes off, revealing the expected circuit boardage, and a glimpse that shows you that the Cable of Immense Cost is firmly anchored in there, so maybe we could have let the camera dangle. The large gray thingie at the top is a counterweight to balance things for the tilt axis.

A close-up shows the 713 (more or less) wires and multiple connectors that make the CIC (Cable of Immense Cost) so immensely costly.

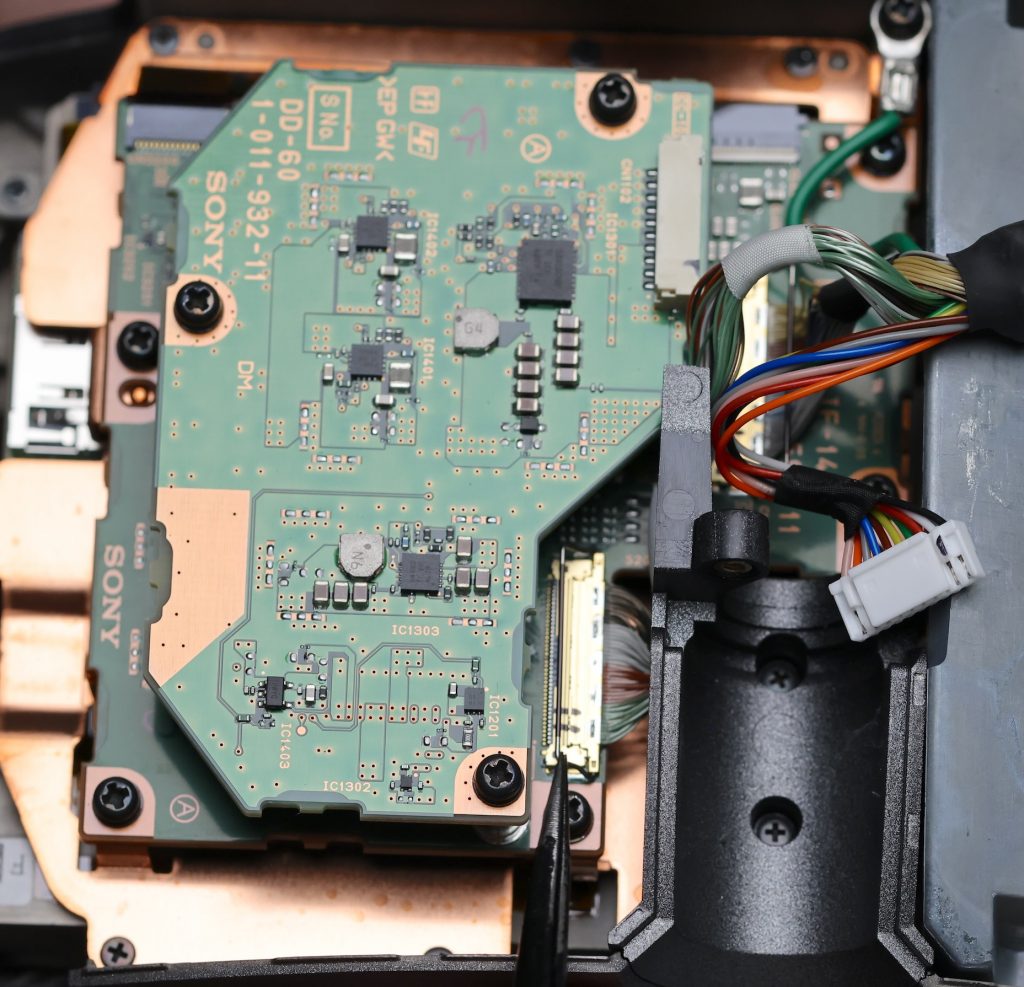

When faced with stacked circuit boards, obviously, the next step is to unclip the I-PEX connectors and start removing boards.

Taking the remaining connectors off the lower PCB, let us unhook the CIC and set the camera down on the worktable. Note again just how chunky (that is the technical term) that counterweight is.

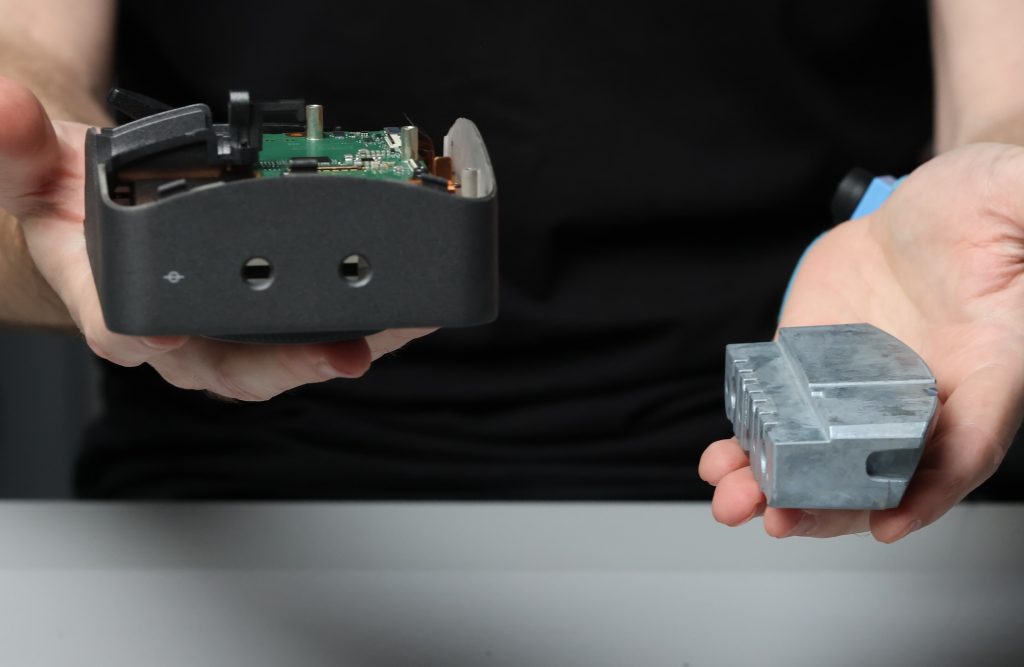

The counterweight is held in by three screws and is impressively heavy. Aaron, having years of experience with weighing stuff, demonstrates that the weight is heavier than the remaining camera using the two-handed balance technique. I, being more scientifically inclined, can tell you the counterweight is a whopping 0.6 kg (1.35 pounds) while the rest of the camera weighs 0.5 kg (less than 1.35 pounds).

You may have noticed the holes for mounting accessories on the top of the camera. They mount right into the counterweight, so this is a pretty robust connection. Remember this robustness, we’re going to wish some other things were so robust later on.

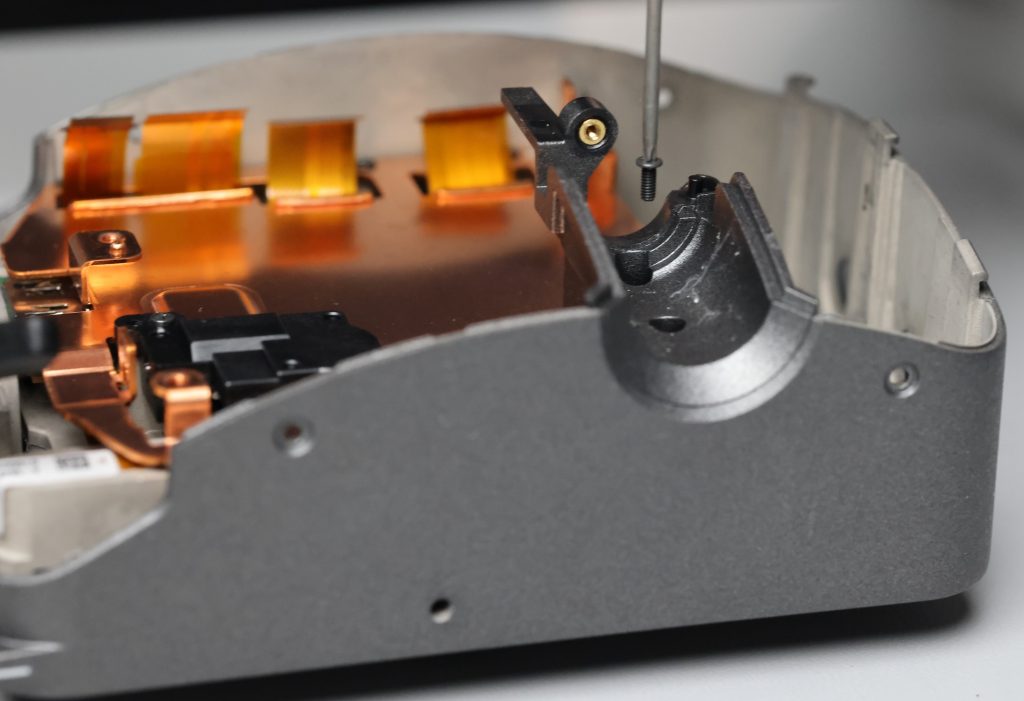

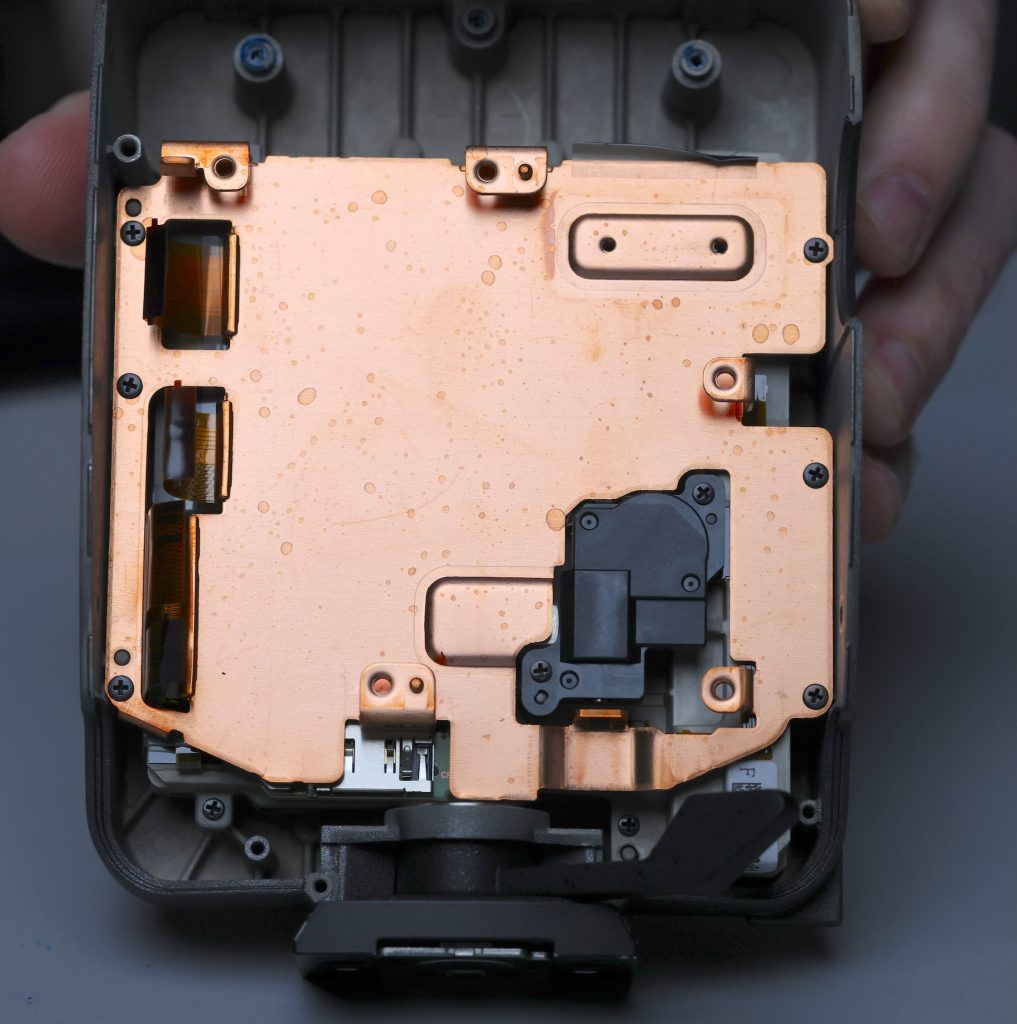

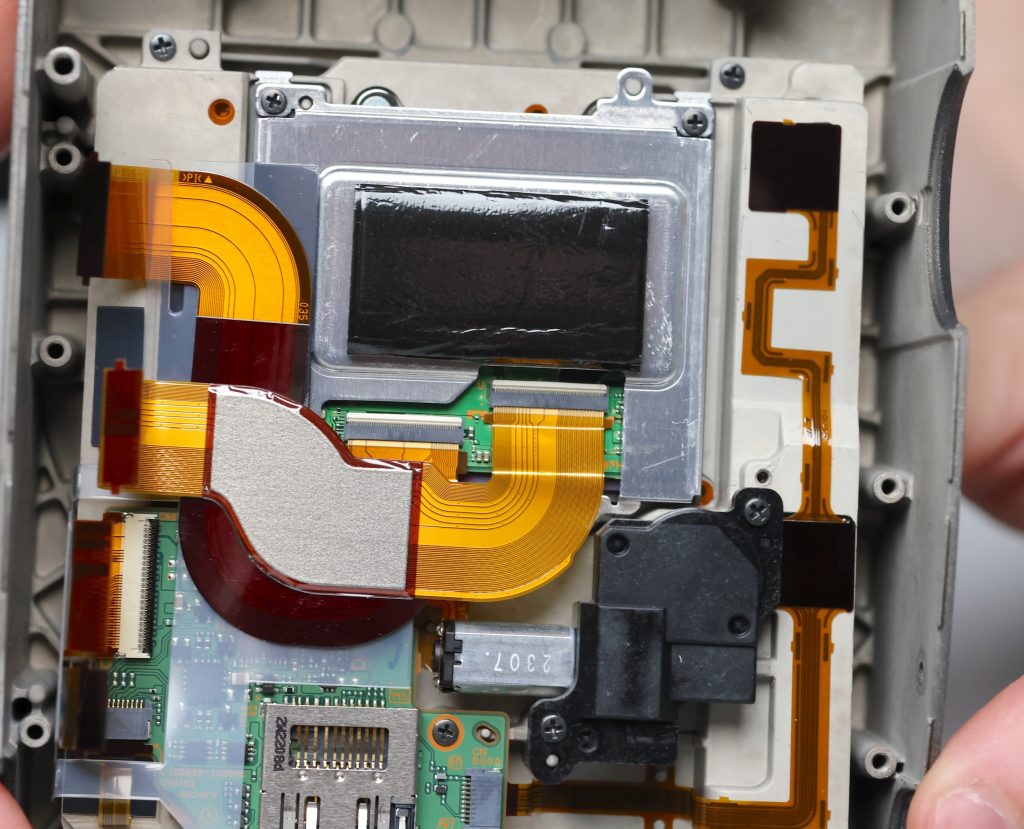

We removed that second PCB and the cable guide next, exposing a copper plate that separates the PCBs from the actual camera sensor. Probably a heat sink, or maybe electronic shielding, maybe both. Probably not just decorative.

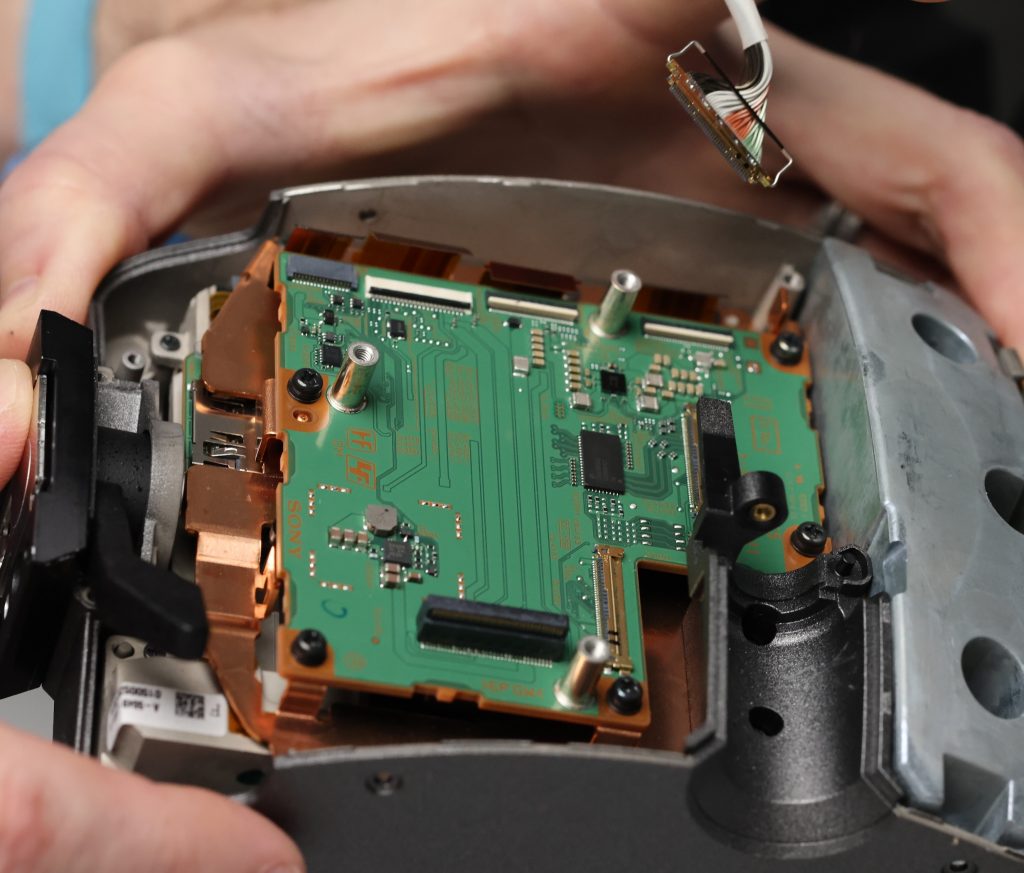

Taking the plate off, exposes the actual sensor assembly, which shows us some interesting things. There is a semi-clear plastic electric shield between the sensor PCB and an impressively large flex cable at the lower left. Also, note the thing that looks like a card reader at the bottom.

This is only accessible from in here and obviously used at the factory, probably during assembly, since it seems the repair center doesn’t go in here often (remember the repair for this is replacing the entire camera). The fast horse would be pixel mapping and adjustment of the sensor, but we don’t rule out that it might be there to tell them stuff like “those Lensrentals guys took me apart thinking you’d never find out”.

The sensor assembly comes out as a single piece.

Remember Why We Came?

OK, this has been fun, but let’s go back to the original reason we’re taking this camera apart: why does the base break, and why is the only repair replacing the entire $6,000 camera?

The why is answered in two steps. First, we take off the lens mount to see if there are shims under there. Nope. Then check for shims in the sensor assembly. Yep, there they are.

What this means is the sensor assembly is shimmed to adjust to the lens mount and case, which will be slightly different for each case and lens mount. In other words, replace the case and you have to re-shim the sensor assembly.

Shimming the sensor assembly is a complex procedure that requires special equipment. We don’t have that kind of equipment, and my guess is that the equipment only exists at the factory, not in the repair center. Hence, the replacement part for a broken case means the entire camera must be replaced, and therefore costs $6,000.

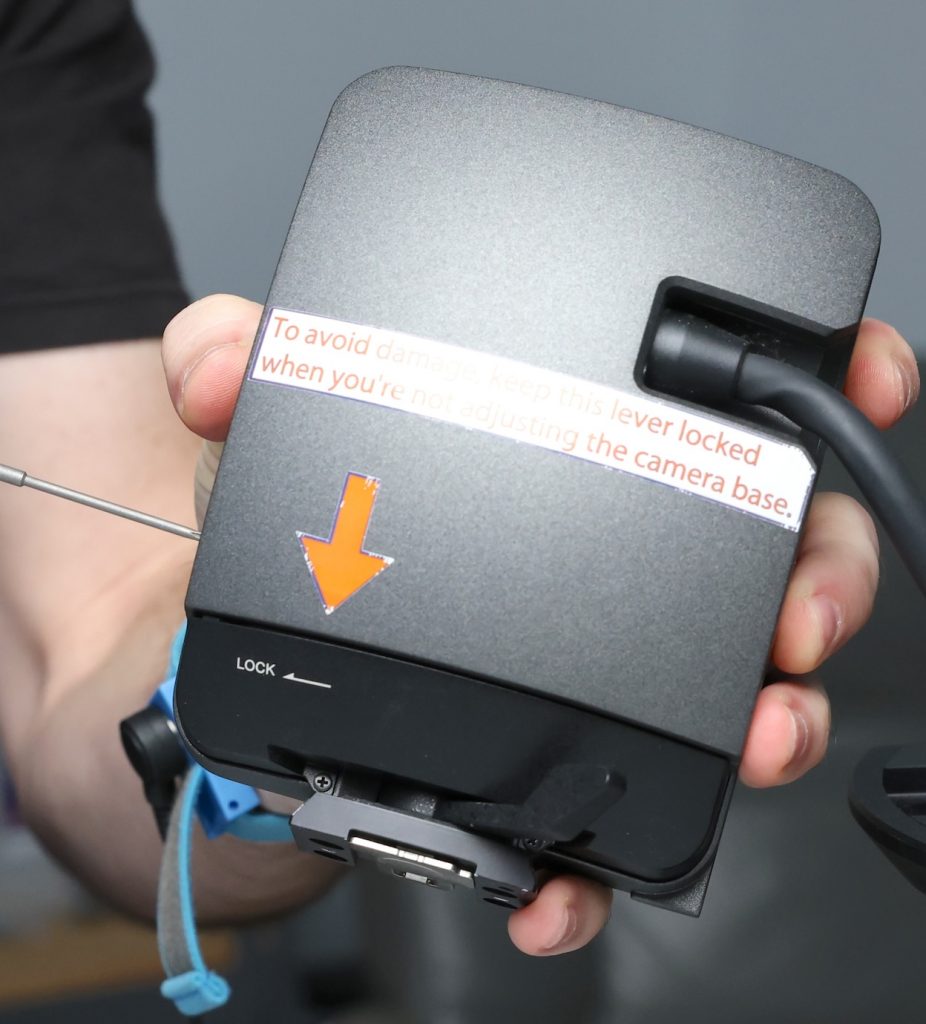

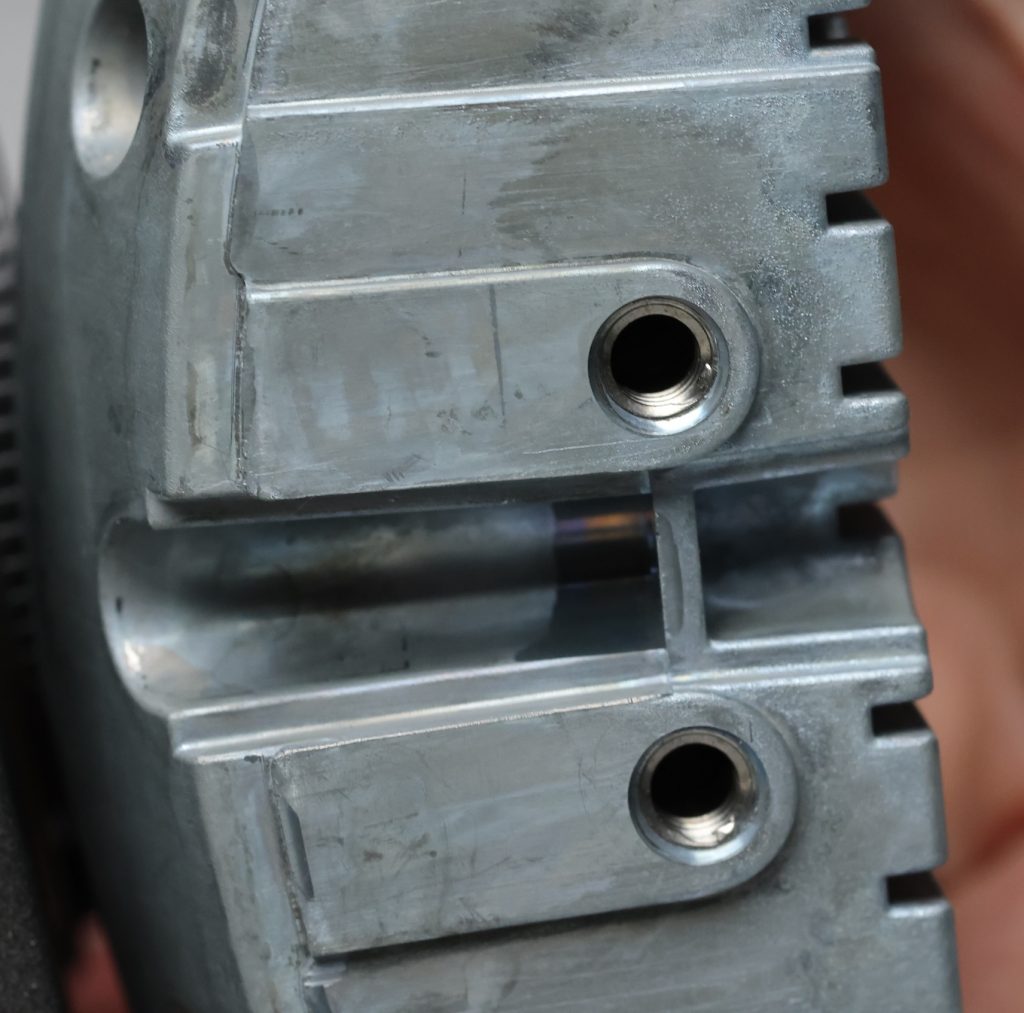

As to why it breaks, that’s pretty obvious. We have a fairly robust mount clamping the camera onto the rail of the PTZ assembly. This holds the 2.5-pound camera, 1.35 pounds of which is a counterweight located as far away from the mount as possible (and therefore having lever-arm type force magnification). And if you are using those mounts at the top of the camera to attach accessories there’s even more weight on an even longer lever arm up there.

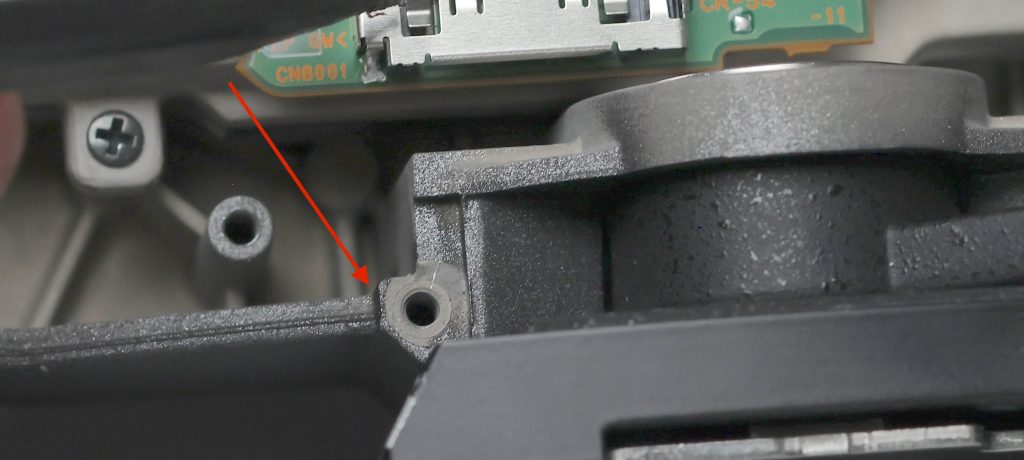

Unfortunately, the robust clamp is attached to a shell of composite material less than 2mm thick (arrow).

The clamp isn’t going to budge when some force is applied; it’s strong as hell. The weak point is between the clamp and that thin shell. Since the clamp is strong, all that force gets transmitted to the thin shell. Put a bunch of torque across that shell, and it’s going to break quicker than the Cowboys get eliminated from the playoffs.

In theory, you could do it by mounting a too-large lens or really heavy accessories, but I doubt that happens very often – that much weight would probably overwhelm the tilt-shift mechanism.

Drop or shock force is the fast horse, especially since this happens in shipping at least sometimes, and the camera is mounted to the rail during shipping. I suspect a significant drop is the most common cause. Hopefully, we can adjust our packaging to provide more support somehow.

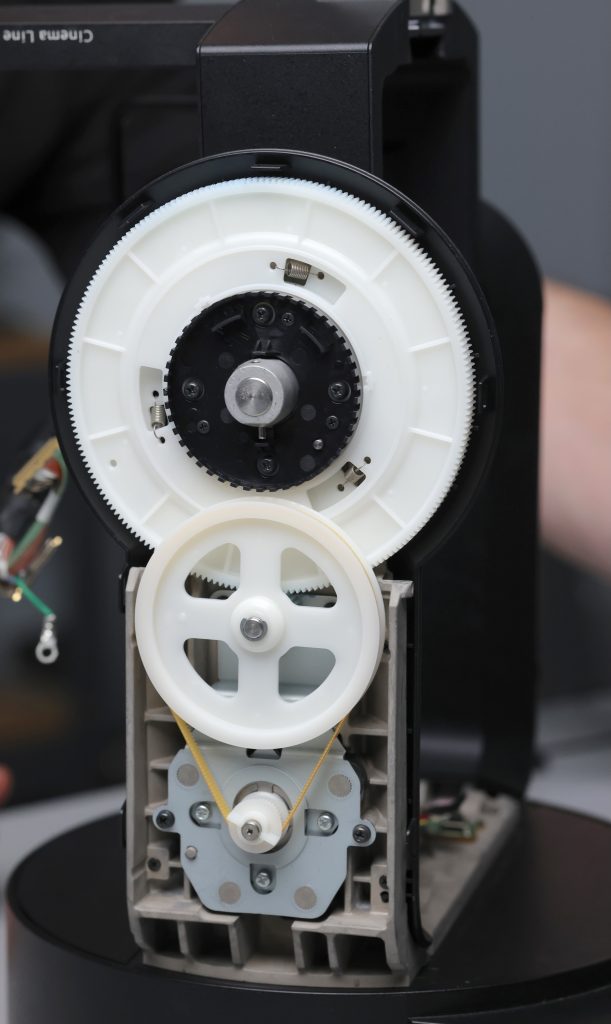

Moving on to more other things, you may have noticed a black plastic box on the back of the sensor assembly about 4 images ago. This is the gearing for the neutral density filter assemblies. Just for fun, here’s a look inside.

I will admit I was hoping to the camera had some kind of fancy electronic ND filter since it’s pricey and all, but really I had no reason to expect this. I just thought it would be cool to see. But mechanical ND filters work just fine, and the ND filters in this camera have never broken on our watch. Just jinxed that, didn’t I?

Oh, Yeah, We Came Here to Fix Stuff

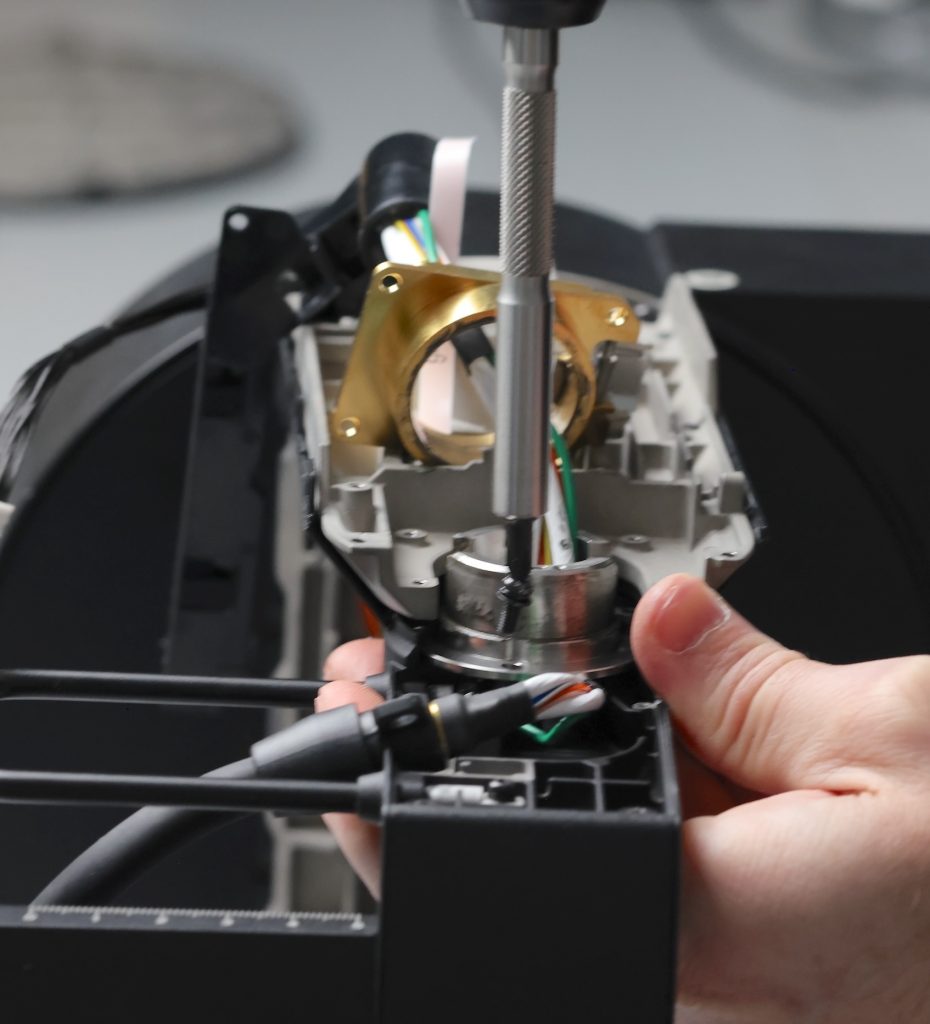

There were two things broken on this copy, neither of which involve the camera we’ve just disassembled: the tilt gear was grinding and there was a bit of separation between the hub and camera. If you look back to the very first picture you can see the small (just a couple mm) gap between the tilt gimbal mount on the left side, which made the locking mechanism not engage as well as it should. And for his own reasons, Aaron wanted to see how difficult it would be to replace the Cable of Immense Cost.

Doing any of these things involves taking the cover plates off the gimbal arms, which is pretty straightforward. See screw, remove screw, take off cover. You might need a spudger to get the cases off; there are also some plastic lock tabs holding them on in addition to the screws. Some screws are located under other covers.

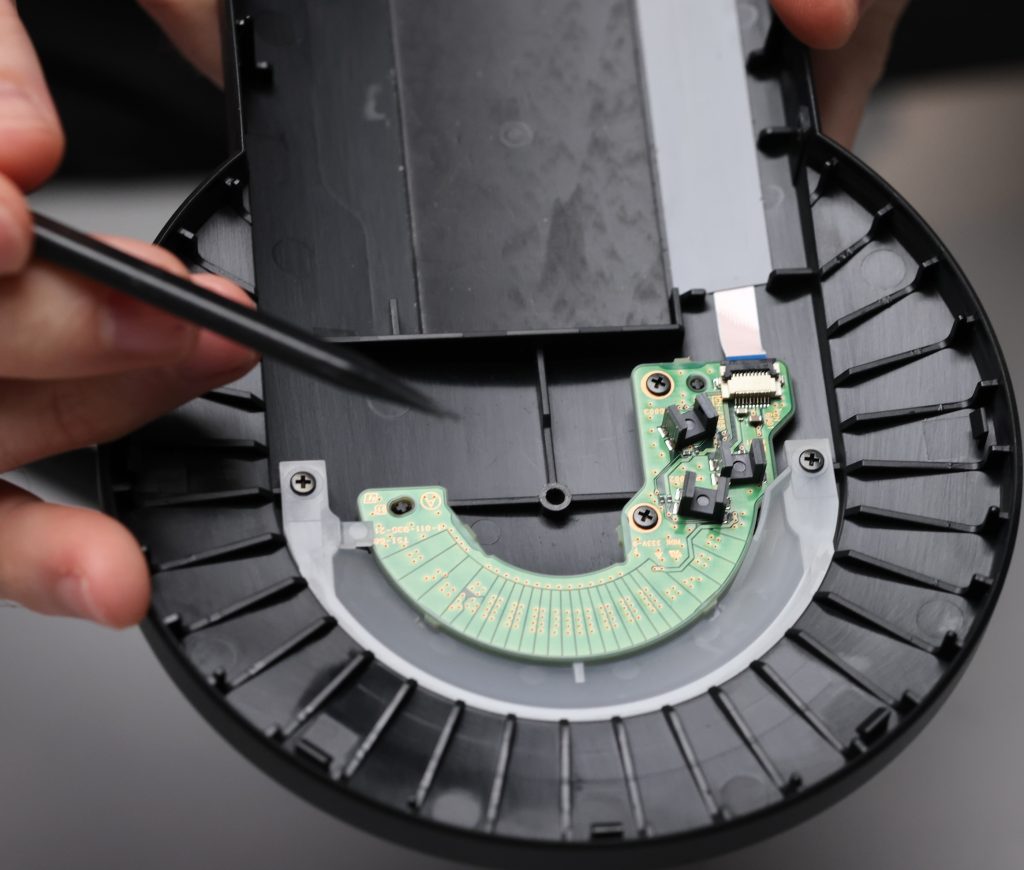

Inside the outside plastic cases, there are some position sensors attached by a flex to the electronics in the arm, so remove the covers partially and undo the flex before tossing them on the workbench.

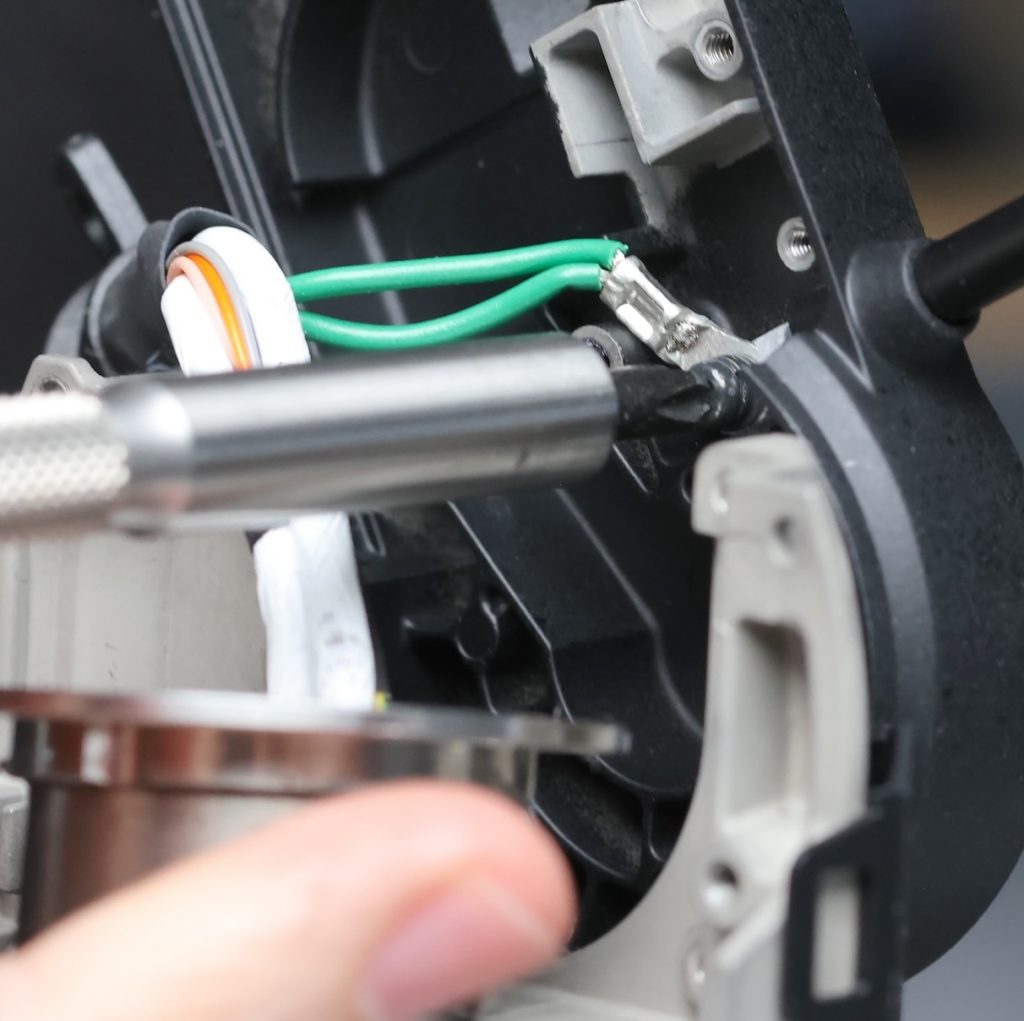

And here we come to our first and easiest fix. The small plastic tab (red arrow) that holds things tight is broken. Take out the two screws holding it and replace it; a 10-minute job. Aaron’s finger is holding down the tilt locking tab, by the way. This gets less locky when the tab is broken and the assembly is loose.

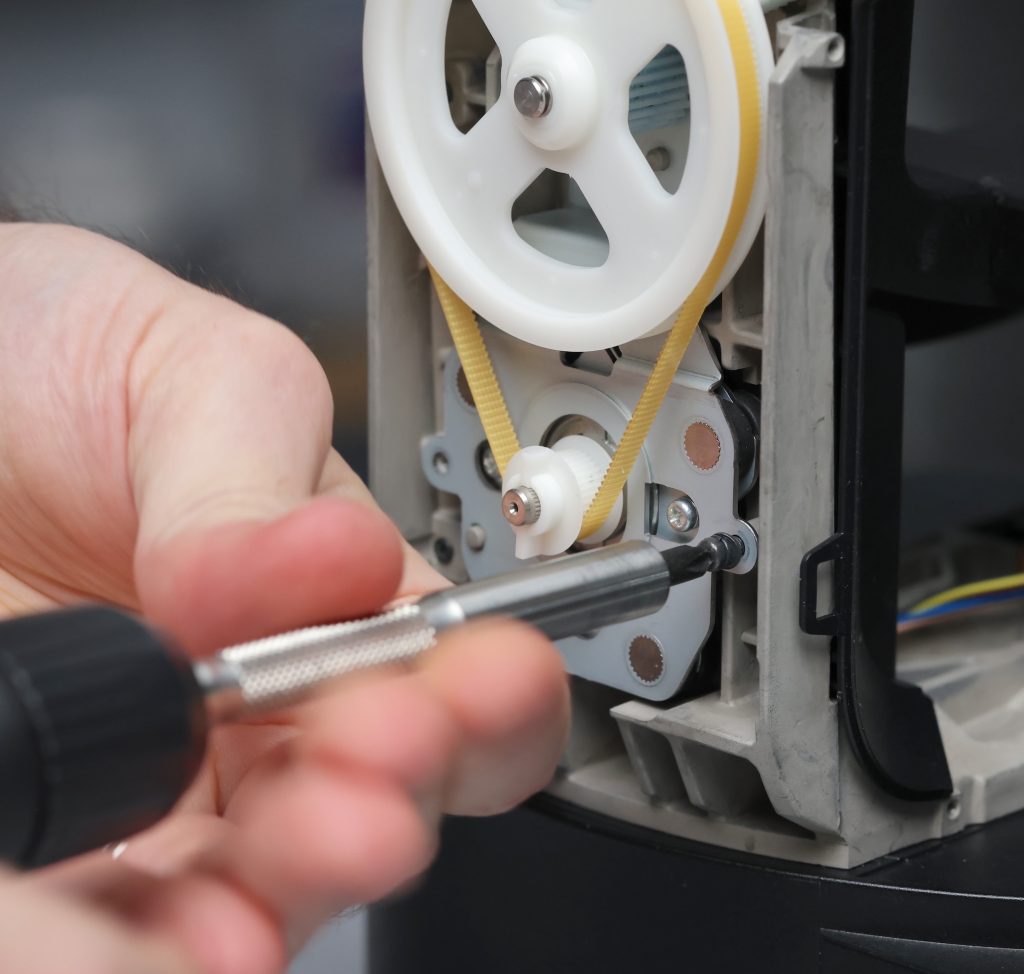

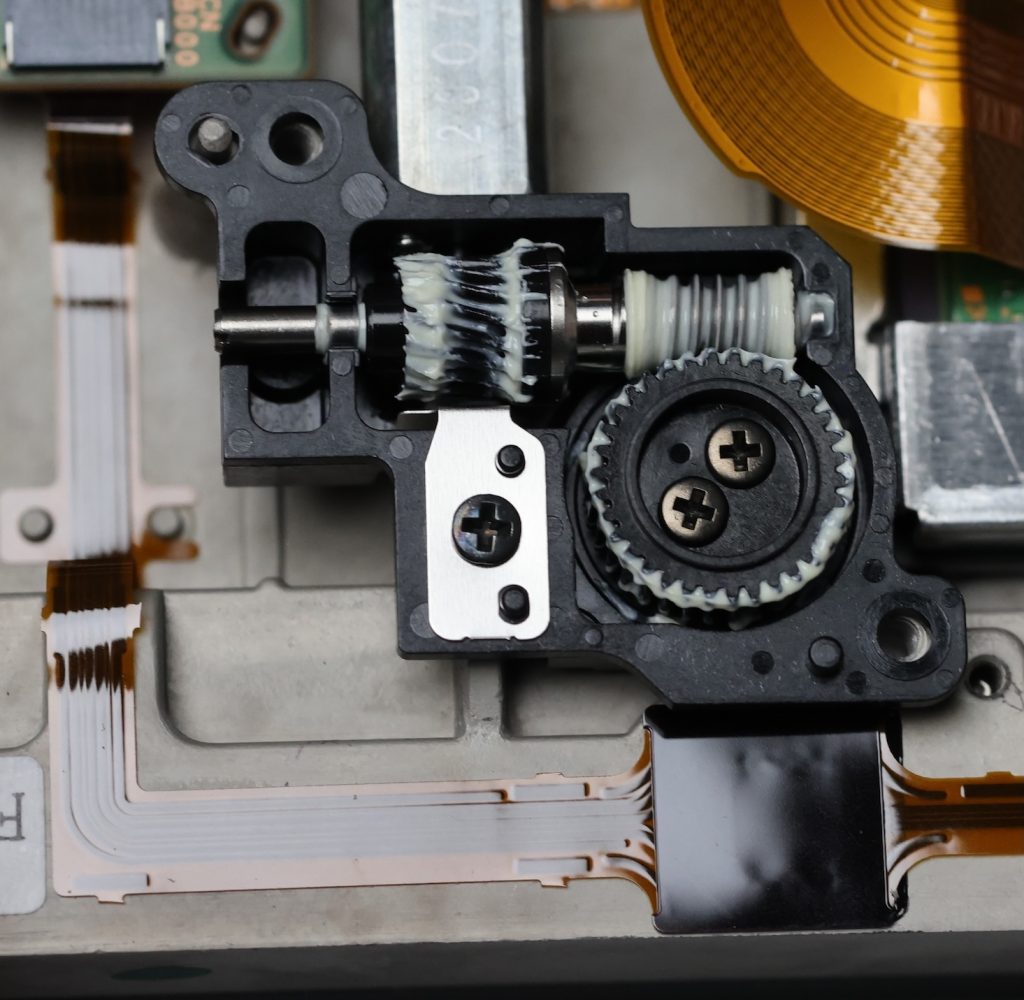

The tilt gear train is on the other side, and there are no wires or cables to work around here.

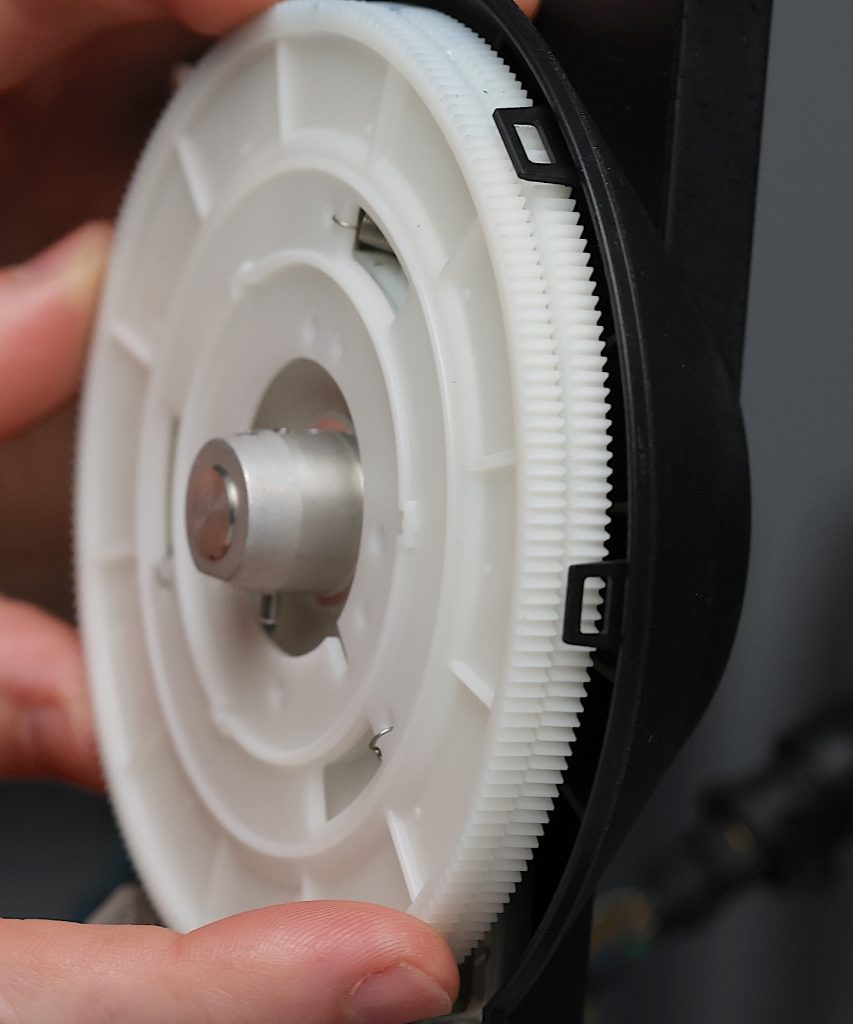

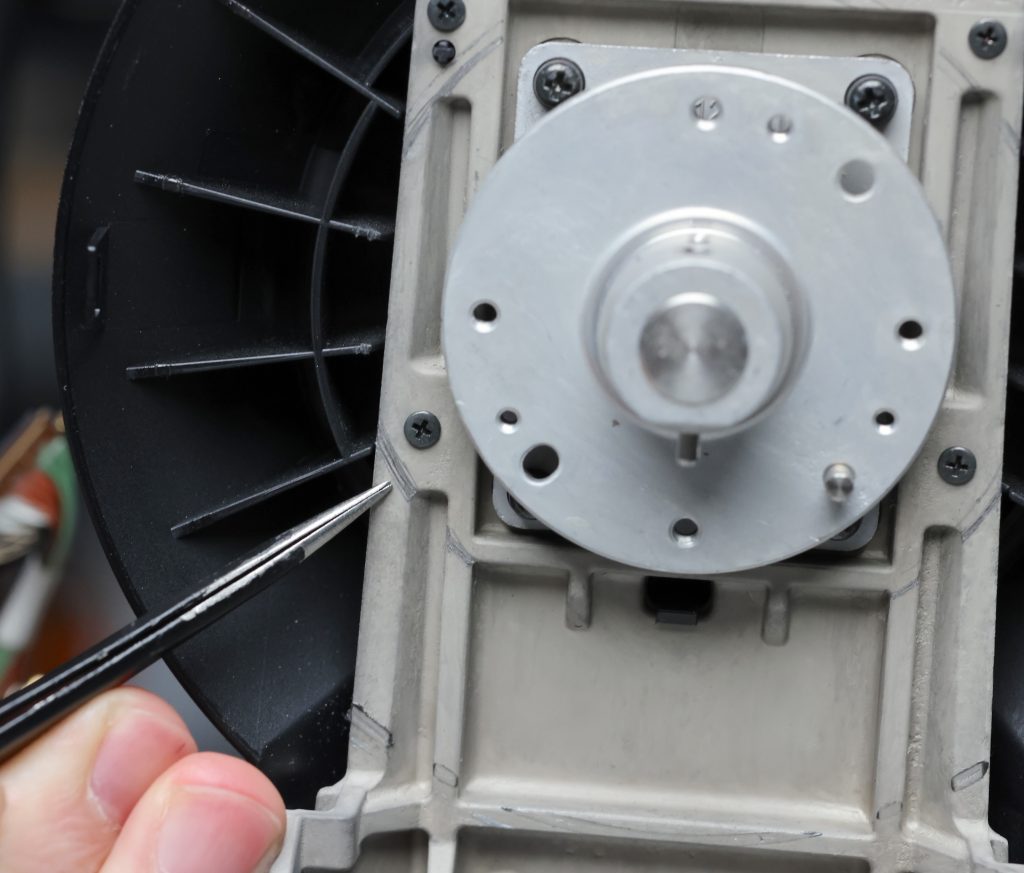

It looks fine at first glance, but the problem occurs in the large gear at the top. If you look closely, you see there are three springs spaced around the gear. We’ll need to take the gear train out to get a closer look at that. It just requires removing a few screws, but some are a bit hidden).

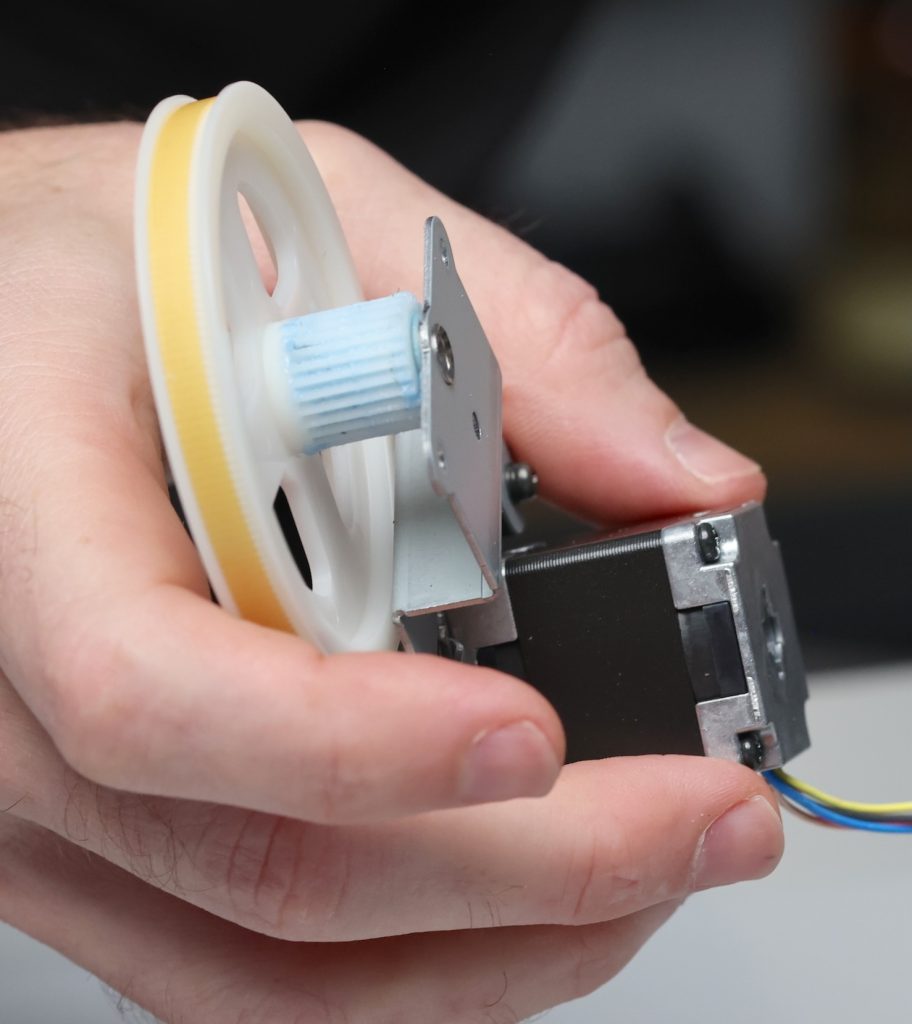

The motor and lower gears are a single unit, quite robust and never (in our experience) a problem.

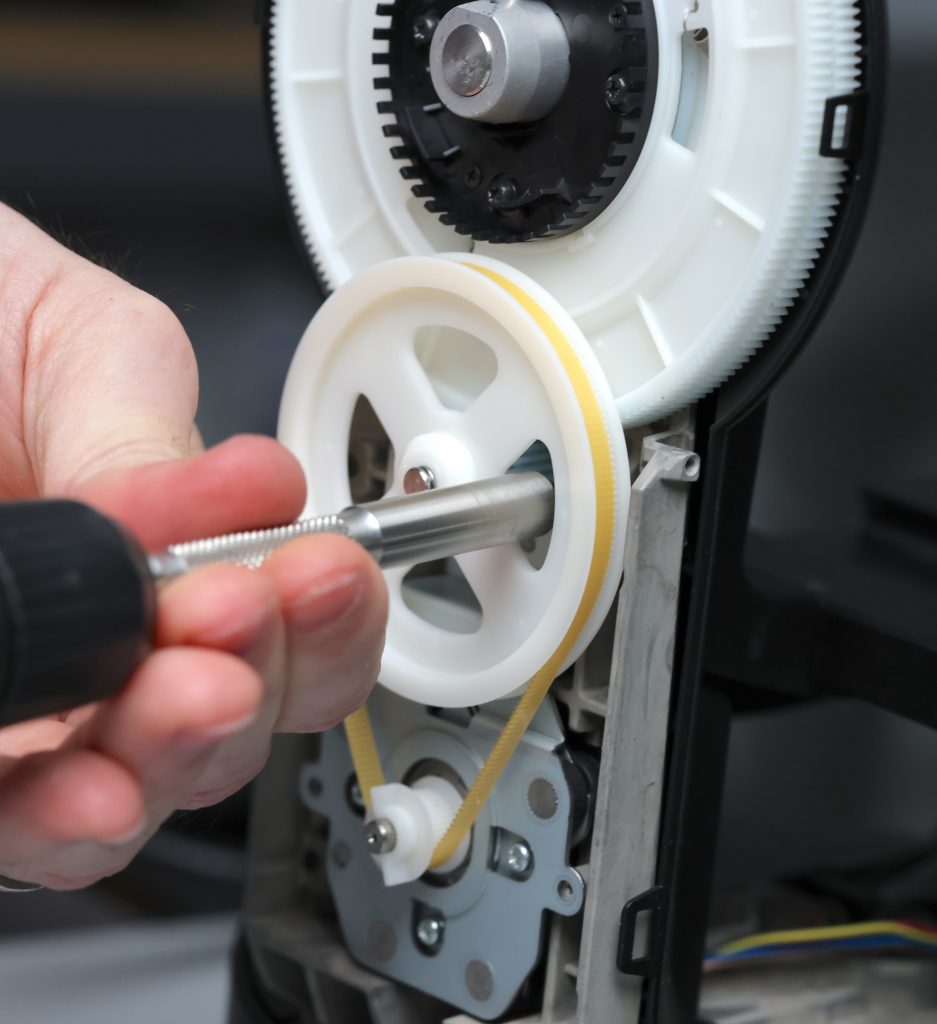

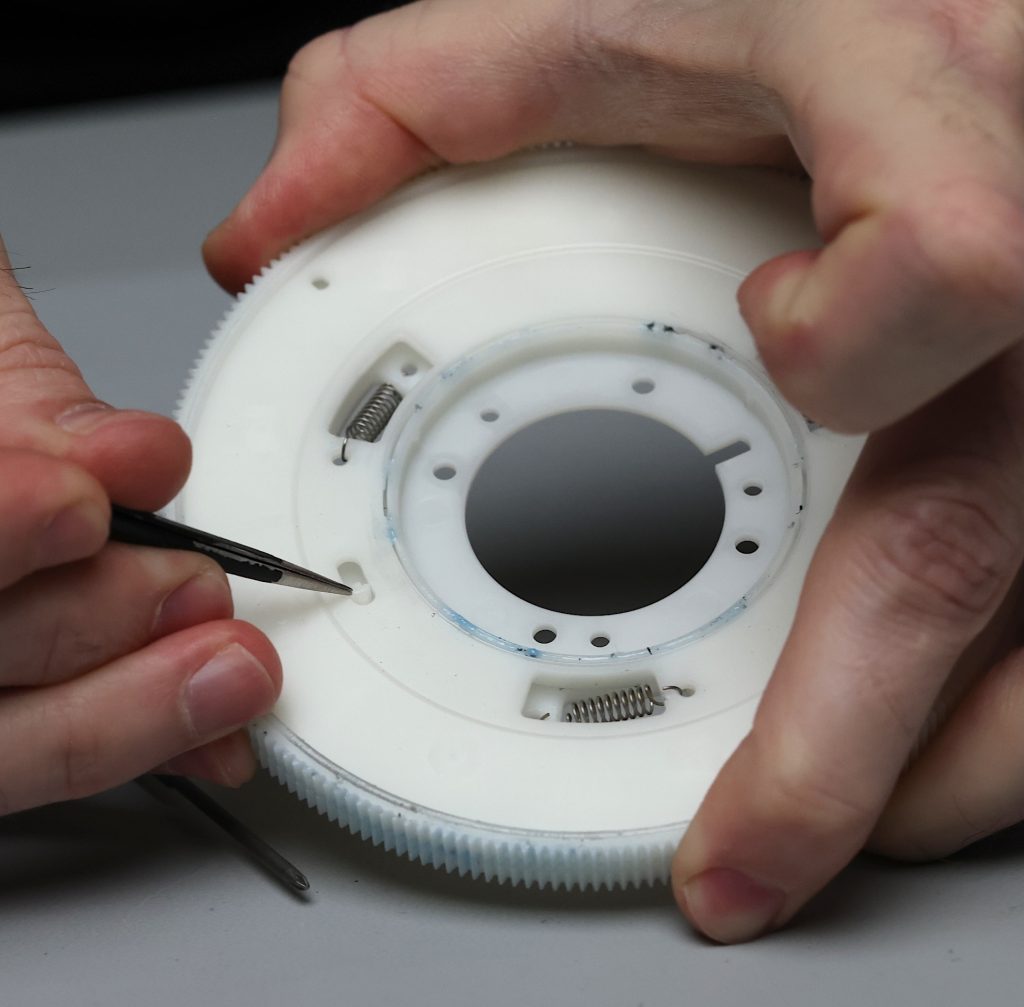

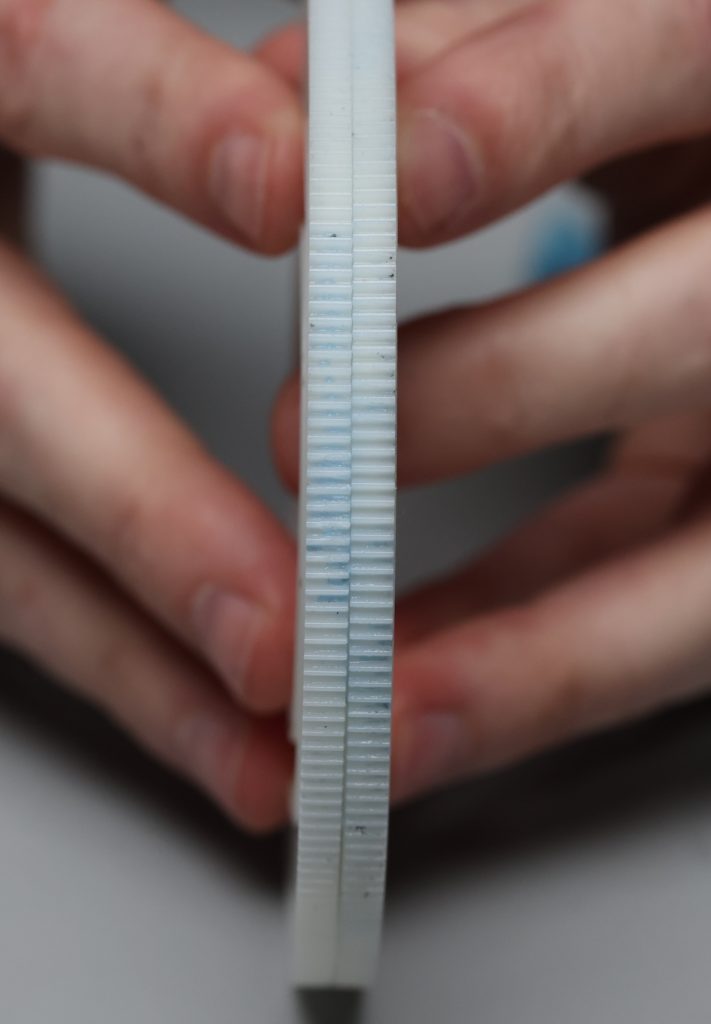

The upper gear is actually a scissor gear: two gears held under tension by those springs we noted earlier. If you look carefully, you can notice that at the bottom, the two gears are tightly touching, but at the top, there’s a bit of a gap between them. There’s not supposed to be a gap.

Taking them off, you see there’s a plastic stop that is supposed to keep tension on the springs holding the gears together. If the stop pops out, the gears are separated, and we have gear anarchy. (It’s back in its proper position in the picture below.)

When everything is put back in proper position, the gears are held tightly together and the gear teeth are a bit offset. With a scissor gear, the spring tension makes these teeth mesh tightly with the smaller driving gear. This eliminates gear noise when the assembly tilts and is the reason it is used here.

But when it’s out of position, as was the case here, it grinds against the housing. You can see some pretty significant scrape marks in the picture below. It’s pretty obvious why it was making a loud scarping noise and not working so good.

We suspect, but don’t know for sure, that this happens when an oversized lens or poor centering of the camera on the tilt plate overloads the gear train.

Oh, Yeah, the Cable

I was ready for lunch at this point, but Aaron wasn’t going anywhere until he’d taken the Cable of Immense Cost out of the camera. Why? So he could put it back in, I guess. But he was in the zone, so I went with the flow.

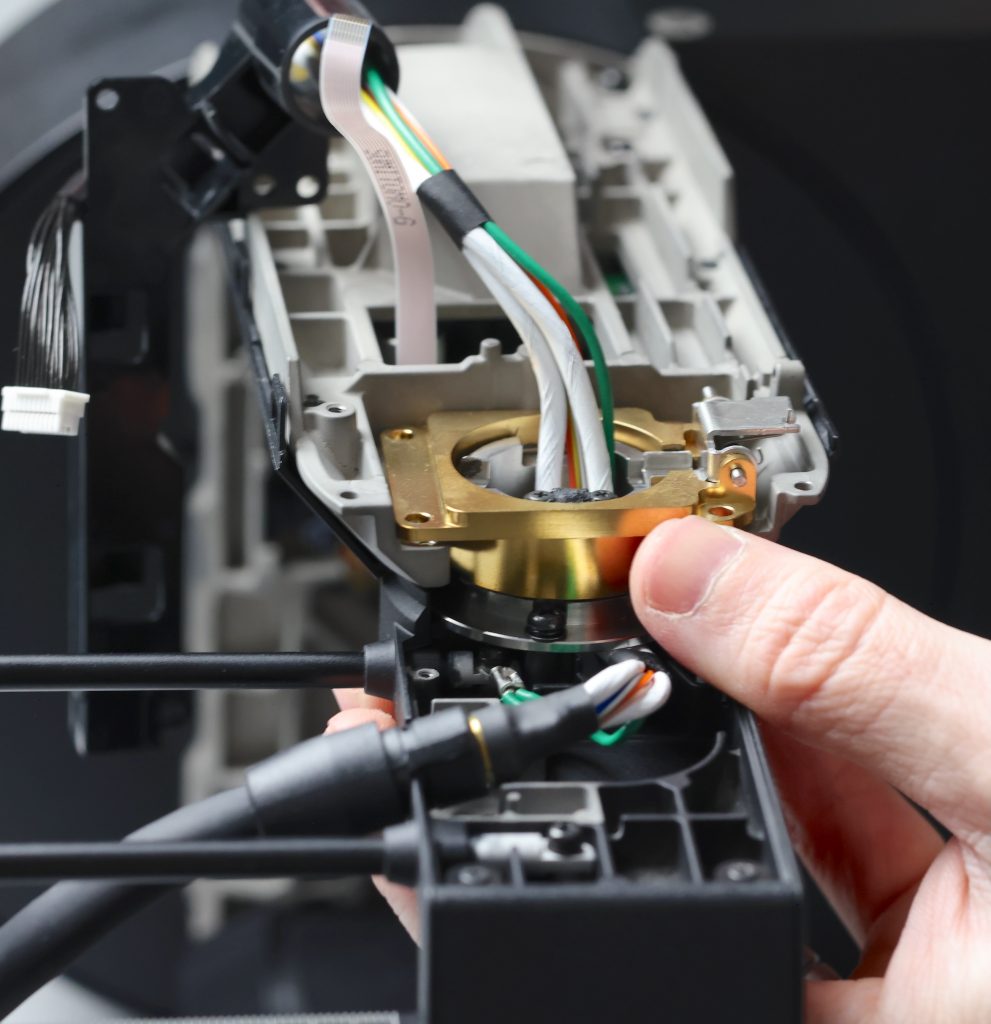

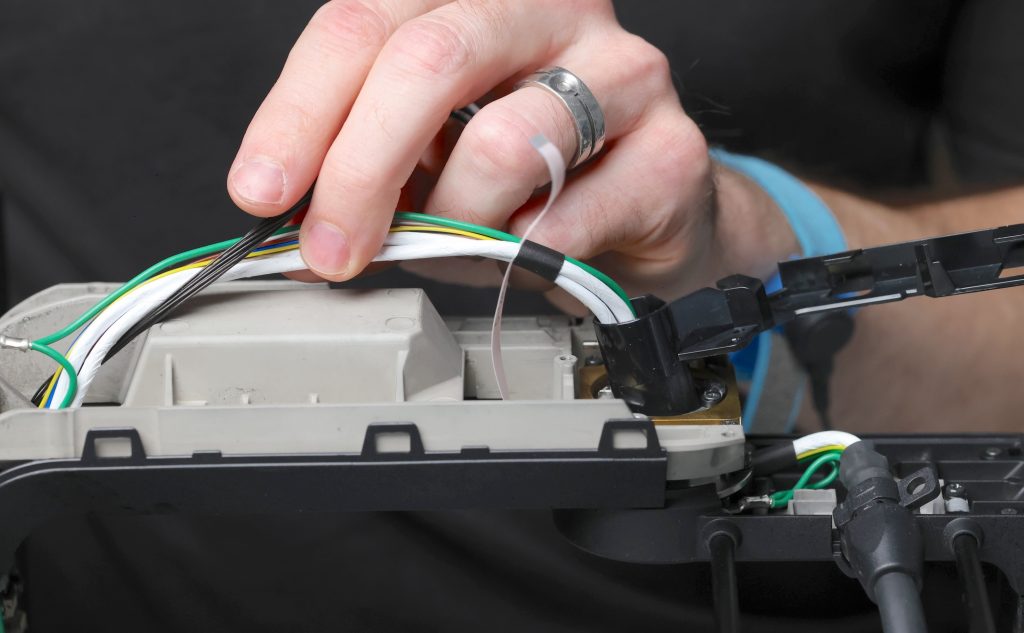

The cable goes down the right side arm of the tilt mechanism. It is braced as it enters (screws already removed on the right side of the image) and then follows a bit of a complex route through the armature assembly.

The two metal pieces of the assembly are each held down by 4 robust screws. As each is removed, we just slide it down the cable for now.

One of the wires in this cable is a green grounding wire that is attached to the housing in several different places.

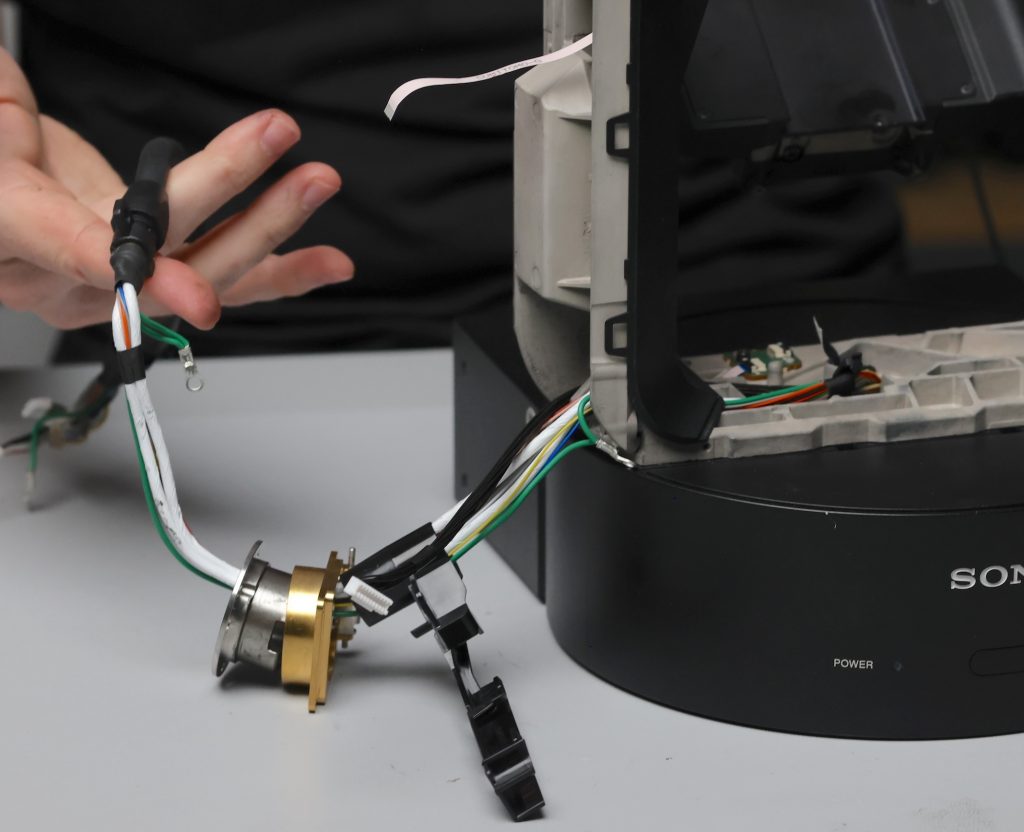

And all that is disconnected, the cable is free of the arm. As you can see, it then goes through a large opening in the bottom of the arm and dives down into the base.

It just takes a few screws to remove the base plate, exposing the main circuit board and all the connections that the cable makes.

Once you disconnect all the I-Pex connectors, the openings are large enough to thread the cable through and out of the camera.

Which resulted in a rather triumphant smirk from Aaron. Why is he smirking? Because I had said this would be a P.I.A. and not worth the trouble, and he got it out in 5 minutes, of course.

So What Did We Accomplish Today?

The most useful information for owners is that if your PTZ starts making noise and jerking during tilting, the fix is simple and doesn’t require any parts. Somebody, somewhere, will save themselves a few weeks of ‘the camera’s off to the service center,’ I bet.

Also, possibly of use is that if the tilt arm gets 2mm of looseness and the lock gets a little sloppy, a really simple repair can fix it, if you can find the part (it’s called a Tilt Shaft Stopper, not a Plastic Clippy Thing that I used in the first draft of this article). 3-D printing the part seems quite doable if you can’t find the part and have a good 3-D printer handy. (Yes, quite doable means we’re probably gonna start doing it.)

Lensrentals learned we might need to try alternative packaging inserts to provide more support for the camera. Shipping the camera unmounted would be great from a prevent breakage standpoint, but would require the user to replace the camera stop and rod lock when they receive the camera. That could cause a whole different set of problems, but probably not $6,000 problems, so we might consider it.

A warning to users that you might not want to mount an overly large lens to this camera is probably in order, and a suggestion to Sony that they might want to strengthen the case base is probably useful here. Previous experience makes me doubt either users or Sony will pay any attention to that, though.

Also, I guess you all learned that Lensrentals is now 19 years old. And finally, we learned, for the 43rd time, that telling Aaron “I don’t think you should take that out” just about guarantees that he’s gonna take it off or out. I already knew that, though, so I didn’t learn it here.

Oh, and you also found out that I’m still on top of the grass, and somewhat functional. And that I’d forgotten how much I enjoyed writing up these teardowns. Might even do another one or two.

Roger Cicala and Aaron Closz

August, 2025

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.-

JosephAndrews

-

Roger Cicala

-

Roger Cicala

-

RecoveredExpert

-

Dave Hachey

-

Gi

-

pl capeli

-

JosephAndrews

-

HenryW

-

geekyrocketguy

-

Roger Cicala

-

Impulse_Vigil

-

NR Admin is a little snowflake

-

John Hall

-

Franz Graphstill

-

Frank Kolwicz

-

Supreme Dalek

-

Roger Cicala

-

Clayton Taylor