Teardowns and Disassembly

Tamron 15-30 f/2.8 Di VC Partial Teardown

We’ve become fans of the Tamron 15-30mm f/2.8 Di VC USD lens since we first tested it optically, but we haven’t really been inside of one yet. It’s not that we weren’t curious. We’ve just been trying to get through the week before and after Memorial Day, typically one of the busier times of the year for the repair department, so we haven’t had time.

But we had two copies show up in the repair department with a jammed zoom mechanism. A peek under the zoom rubber didn’t show any obvious problems. So we needed to open them up and see what was wrong, and thought we’d take some pictures along the way. This is a rather different looking lens and we were curious if it was different inside too.

-

- All photos copyright Roger Cicala and Lensrentals.com, 2015

This isn’t one of our classic teardowns done just for demonstration purposes, though. The fact that the lens has a jammed zoom means that normal disassembly procedures may not work. With most zoom lenses standard disassembly requires you have to have the lens in a certain zoom position to take this off, a different zoom position to take that off.

Also I’m writing this up ‘as we go’. I thought it might be fun for some of you, at least, to see what it’s like when we try to figure out what’s wrong with a lens that we don’t know very well.

Front End Disassembly

We weren’t quite sure what the best way into this lens was so we just started at the front. There is a stick-on makeup ring that has to be peeled off before we get to work.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Removing that exposes several different screws, some of which hold the front group in place.

-

- All photos copyright Roger Cicala and Lensrentals.com, 2015

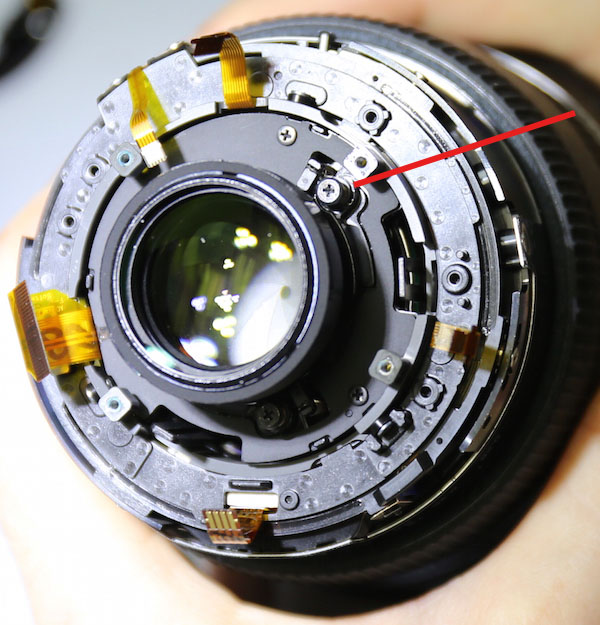

Remove three screws and the big, sealed front group comes out in one piece. That’s the good news for all of you who plan on disassembling your copy for fun and profit – getting the front group out couldn’t be simpler. Notice there’s a nice, robust seal (red arrow) on the back surface of the group. The rear element of this group could be removed, but there was no need to do that for this problem.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

- All photos copyright Roger Cicala and Lensrentals.com, 2015

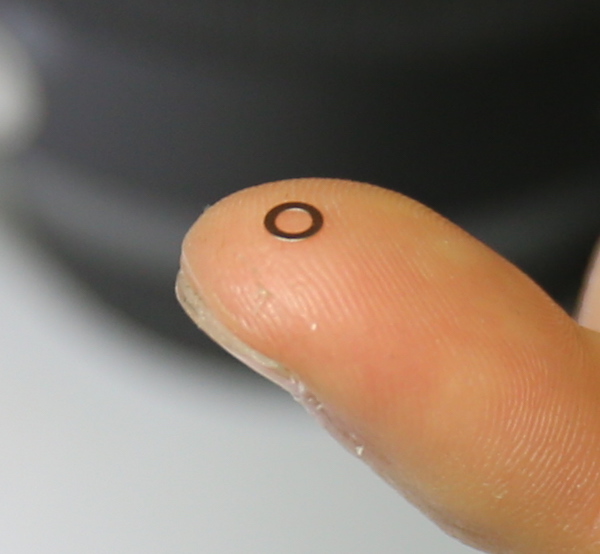

The bad news about this front group is it has a complex set of shims. mostly held in place by the screws that we had removed to take out the element. From the glass side down, first there are a couple of tiny round shims at each of three locations.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

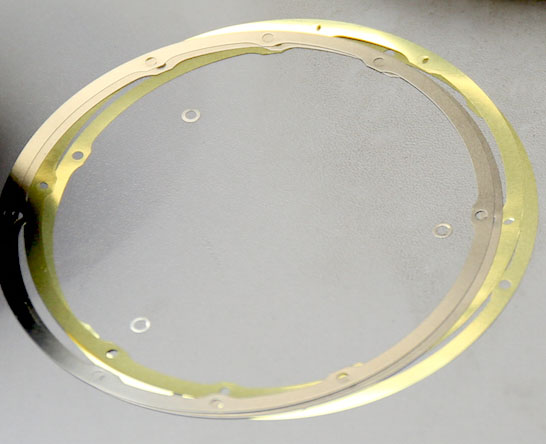

Under which are several ring shims of various thicknesses. Under the ring shims are another one or two tiny round shims at each screw location.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

So with the screws gone nothing holds this 8-deep (your number may vary) stack of shims in place. A stack of 8 shims isn’t very stable, so the shims are going to tend to fall out of place. When the shims fall out of place you don’t know which ones went where. When you don’t know which ones went where, you get to spend an hour or two optically testing the lens and moving them around until you get the lens optically correct again during reassembly.

My own method of dealing with the situation is to volunteer to write up the report while Aaron fixes the optics and does the reassembly. You don’t have that option, so I really wouldn’t recommend taking the front glass out of your Tamron 15-30 f/2.8 VC unless you’re really comfortable with lens disassembly and optically adjustment.

After we’d collected all the shims from where they fell inside and outside the lens, we got back to disassembly. There are several screws under the ring shims that hold the inner petal hood in place.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

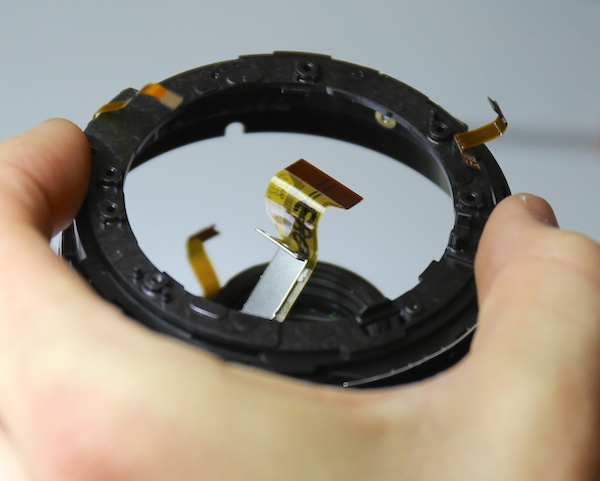

With these removed, the inner hood comes right out. Again there is a nice, thick, gasket around the bottom of the hood, and some optically black felt lining the outside. This the way it should be, helping to dust and light seal the lens, but too often we see things aren’t taken care of properly like this.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Unfortunately, removing all of the front glass and inner hood accomplished nothing more than letting us look down inside the lens. We still didn’t have any access to whatever was causing the zoom to jam.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Rear Disassembly

So we flipped the lens over and began rear disassembly by first removing the rear light baffle.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

And then the rear mount and electrical connections can be removed. (This is a Nikon mount, hence the mechanical aperture system.) Of course, there are more shims under the lens mount. There is also a nice thick weather-sealing gasket around the bayonet mount. Weather sealing, for those of you who aren’t aware, means “the manufacturer still doesn’t cover water damage”, but some of you really are interested in it, so I thought I’d mention it.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

With the shims out out of the way, the 4 screws holding the outer rear barrel in place can be removed and the rear barrel taken off.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

For those of you following along at home and disassembling your own lens, note that the GMR unit is now exposed. Touch it and your lens dies, pretty much.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

There’s a solid metal inner barrel that gets removed next. This basically connects the bayonet mount on one side to the lens body on the other.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

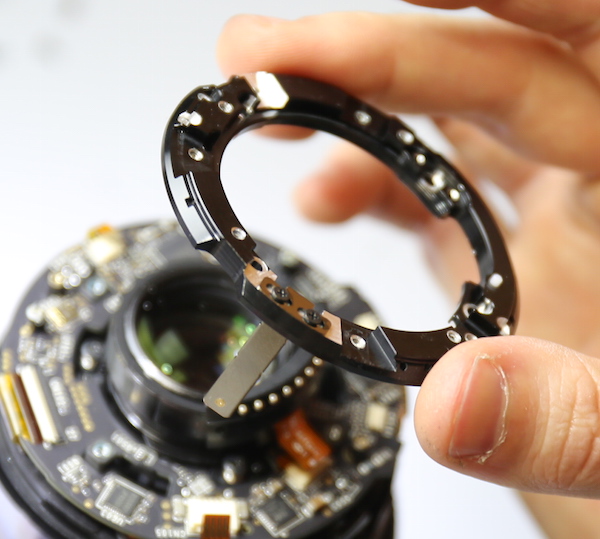

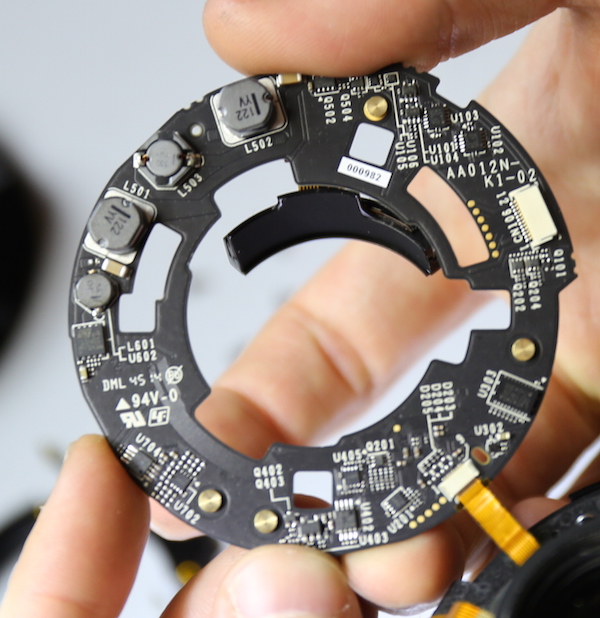

After which flexes can be disconnected and the PCB board removed. Like most Tamron lenses, the PCB is rather sexy (to a Geek) in basic black, unlike the green and blue-green PCBs most manufacturers use.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

If you’ve followed other tear-downs we’ve done, you’re probably getting the idea that this one, while not complex, is a bit more tedious than most. That would be a correct impression. But now that we have all these various pieces removed, we start to get down to the mechanical workings of the lens.

We can now remove what I thought was the focus key (being held by the forceps). I was, as is so often the case, less correct than I would like to admit. It actually is just a metal plate that holds the flex (the one just above the forceps) in place as it goes down through the lens.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

The rear group is held in place by several large, spring-loaded screws that just scream “I’m a centering element, if you remove me I will make your life a living hell as you try to recenter me.”

- All photos copyright Roger Cicala and Lensrentals.com, 2015

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Either by luck, or by good design (I’d say the possibilities are about equal), the inner rear barrel can be removed by taking out several side-mount screws. The rear-element centering system isn’t disturbed at all.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Which lets us remove the rear inner barrel without touching the rear optics.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

We’ve now got the focus motor exposed, but still aren’t seeing anything causing the zoom mechanism to jam.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

The focus ring comes off now when turned to the proper location.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

After which the screws holding the focus motor in place are visible.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

After removing these the focus motor can be taken off of the barrel.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

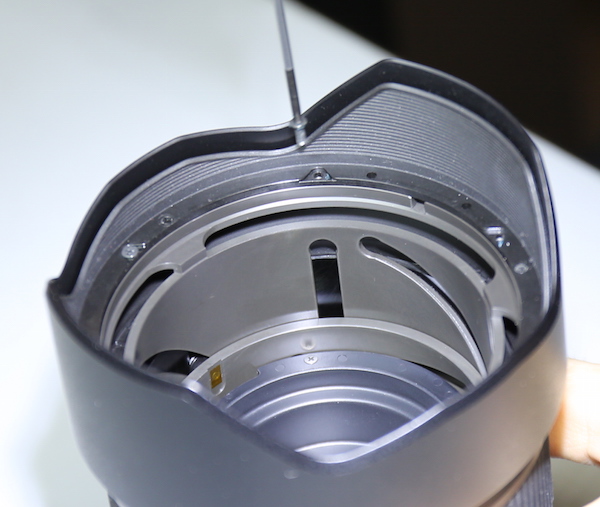

With the motor off, most of the helicoids for the zoom and focusing mechanism are exposed, but we still can’t find any reason that the zoom is jammed.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

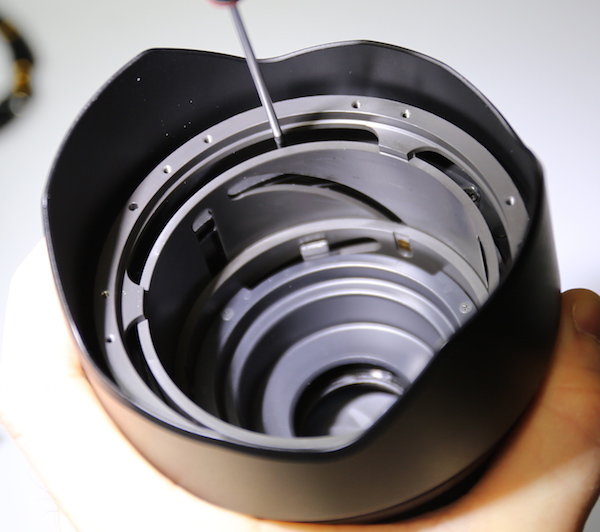

We turned things back over at this point, first removing the deep inner baffles.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

- All photos copyright Roger Cicala and Lensrentals.com, 2015

Still no joy, however, as the inner barrel still shows no sign of what’s causing our zoom jam.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

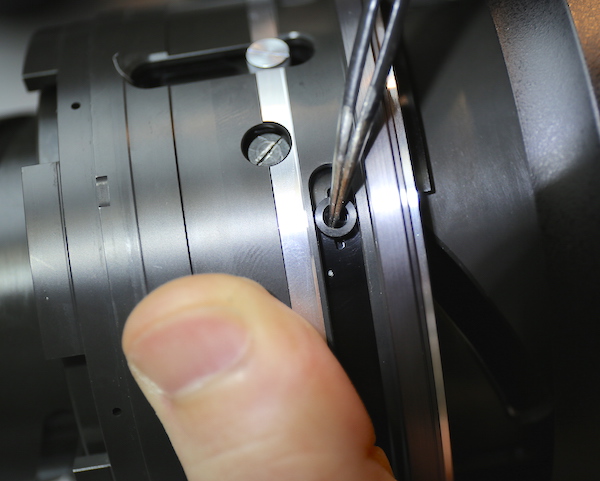

Looking around, we found another set of screws that seemed to hold the front barrel and outer hood on. Because the zoom mechanism was jammed, we couldn’t move the barrel to get to these very easily which led to the rather different technique of loosening the screws from above. . . .

- All photos copyright Roger Cicala and Lensrentals.com, 2015

And then removing the loosened screws through the helicoids.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

At this point it became obvious that the front barrel did not come off over the front of the lens, it had to be taken back over the rear, which meant removing the mid barrel. This does have some real-world implications: when the built-in hood breaks, replacing it is going to require a near complete disassembly. Anyway, at this point taking out 4 more screws let us take the mid barrel off.

All photos copyright Roger Cicala and Lensrentals.com, 2015

Which let us remove the zoom ring.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

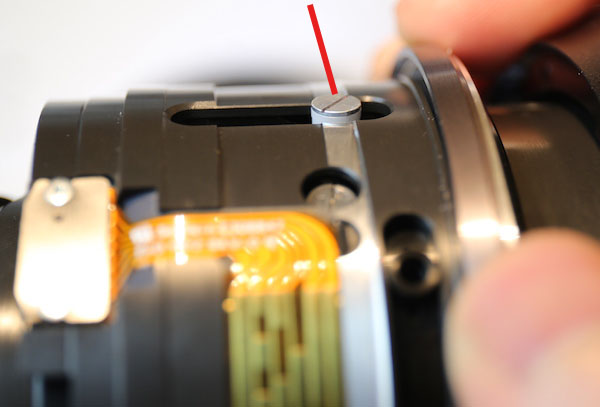

At this point we found that there was not a classic zoom key, rather there were several of these metal ‘plugs’.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

The flat base of the plug sits in a slot inside the zoom ring (red arrow)

- All photos copyright Roger Cicala and Lensrentals.com, 2015

And the inner slot inserts into openings in the inner zoom mechanism (where the forceps are) so that turning the ring turns the inner zoom mechanism. Its not an uncommon system for attaching the zoom ring; most larger zooms use a similar system.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

At this point, after looking at the keyholes and posts and ring for about 5 minutes, we still had no damn clue what was jamming the zoom mechanism.

All photos copyright Roger Cicala and Lensrentals.com, 2015

But then when we looked back at the exposed inner barrels the problem became obvious. The large guide screws and collars that the barrel slides along (they keep it sliding back and forth in a straight line) had loosened and backed out. One of them poked way up through it’s opening and had been jamming the zoom ring. Simply tightening it back (with a generous dose of loctite to hopefully keep it where it belongs) restored the zoom to normal function.

- All photos copyright Roger Cicala and Lensrentals.com, 2015

And yes, because someone always asks, the lens was reassembled, optically corrected, tested, and works perfectly. It’s back in the rental fleet now.

So, Mr. Wizard, What Did We Learn Today?

Well, a couple of things. First, figuring out how to work on a lens without having access to any repair manuals requires a bit of trial-and-error. It’s not quite as slick and smooth as we’d like it to be. But I thought you might enjoy seeing what it’s like. If we need to do this again, for example, we don’t need to do any disassembly of the front. The screws in question could be reached by just the rear disassembly.

Second, we found that the Tamron 15-30 f/2.8 is a well built lens, but certainly not very modular in construction. Where a modular lens, such as the newer Canon lenses, separates easily into three sub-assemblies, the Tamron came apart in lots of separate pieces as shown in the picture below. And we hadn’t done anything like a complete disassembly. None of the optical elements or helicoids had been touched yet and the front barrel was still on.

All photos copyright Roger Cicala and Lensrentals.com, 2015

Getting in and out of it is not complicated or difficult, but it’s definitely more tedious than a modular design. How does this affect you? Not at all. Tamron has a really good service department, consistently ranking high on our list. Their techs probably wish the lens was more modular (I know we do) but they’ll be able to fix it just fine.

Two things that might be worth noting, though. Replacing the built-in front petal hood isn’t simply removing a couple of screws and replacing the hood, it requires a significant disassembly of the lens. So don’t drop yours on concrete. And since we’ve seen two of these zoom jams already, well, at least now you’ll know what’s causing it if it happens to yours. I doubt any of you will want to try to fix it yourself at home, but it should be easy and simple for it to be fixed at the service center should it happen to you. And I suspect they’ll throw some extra loctite on there just like we did.

Roger Cicala and Aaron Closz

Lensrentals.com

June, 2015

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Andy

-

Danny Wilson

-

Ray Repede

-

Lynn Allan

-

Mogens Werth

-

RAY REPEDE

-

Randy

-

Jorgen Risum

-

Ilya Zakharevich

-

Ralph Conway

-

Matthew Saville

-

Joseph Andrews

-

Tim

-

Stuart

-

Michael Reed

-

Jim Kramer

-

Shane

-

Nqina Dlamini

-

erno james

-

Lyle

-

Don Keller

-

Don Keller

-

Sam