Geek Articles

Taking Apart the New Nikon 105mm f/1.4E ED AF-S

Lensrentals.com, 2016

We recently tested the Nikon 105mm f/1.4E ED AF-S lens and were mightily impressed. Optically it was better than I’d ever expected. We had idly talked about doing a teardown when stock allowed, but we got an unexpected opportunity yesterday: one of our week-old copies had some significant dust in both the front and rear lens groups. We know (like hopefully you know) that some dust doesn’t affect images, but our customers like their lenses dust-free, so we decided to open this one up and clean the dust out of it and to take a few pictures while we were doing it.

I try to identify where my head is whenever I write about anything, so you’ll understand when I go all fan-boy or all snarky. Like everyone else, my expectations going in have a lot to do with my impressions coming out. In this case, I told Aaron before we started that given how awesome this lens was optically that I expected Nikon’s optomechanics were going to modernize, too. Unlike previous Nikon lenses, I thought this lens would have nice, modular construction, no soldered wires running hither and yon, not so much Kapton tape holding stuff down, and maybe even some curved circuit boards. You know, like a lens from the 21st century, not like one from the 1980’s. Aaron didn’t think so.

Well, I was a little bit right but mostly wrong. There is some real modularity and superb construction to this lens. There were also big chunky square circuit boards and wires soldered hither and yon held down with Kapton tape. None of which has anything to do with making a lens take better pictures or making it last longer, but it does make it a pain to take apart and work on.

Oh, and we have a special bonus in this teardown. I thought Nikon’s marketing for this lens got a little nauseating with stuff like “pushes boundaries of imaging possibility, one that can take your photography and videography to a thrilling new level.” I figured with all the workforce reduction they’d been making; they’d started borrowing Leica’s copy writers or something. But in this case, they take stretching the bounds of reality a bit far, and I’ll go all snarky about that later in the teardown. So you’ve got that to look forward to.

So Let’s Take Out Screws and Stuff!

Since we’d never taken one of these apart, Aaron decided to start with the back, because that way he could set it on the front while he worked. The bayonet mount comes off in the usual fashion; easier now that Nikon has gone to electronic aperture controls. There is a nice, thick weather seal around the bayonet mount and it fit very snugly in the lens.

Lensrentals.com, 2016

With the bayonet off, we can look into the rear barrel. It’s nice and clean, with a couple of flexes just visible up by the electronic connector.

Lensrentals.com, 2016

Four large screws held the rear barrel in place. For those of you following along at home by disassembling your own copy, make sure you remove the screws holding the flexes in place and disconnect them, otherwise you’ll rip them out of the switches on the rear barrel. With that done, the rear barrel slides right off. Notice the thick layer of felt sealing at the bottom of the picture where the barrels attach.

Lensrentals.com, 2016

Here’s the inside of the rear barrel, with the switch flexes I spoke of above. Soldered, not plug-ins, but after some argument Aaron agreed this didn’t count as a real solder. Does it matter? Not much, except if you break a switch it’s may be simpler for the repair shop to just replace the rear barrel instead of the broken switch. On the other hand, some might argue that soldered switches are stronger and less likely to break. Some might.

Lensrentals.com, 2016

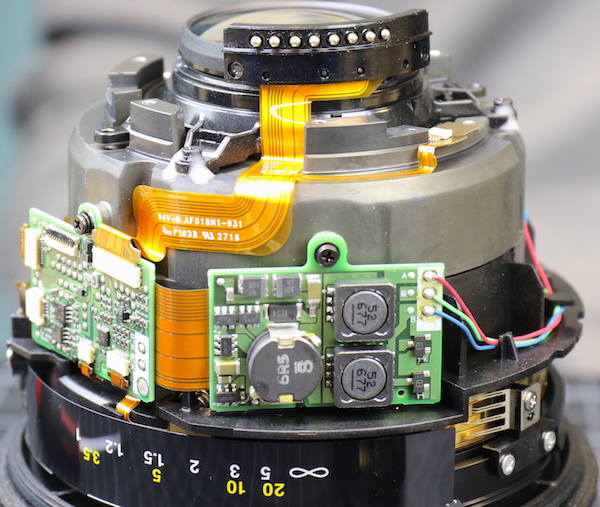

With the rear barrel off, we get to look at the inner mechanics a bit. This is where I lost my bet with Aaron that the lens would be more modern. This would also be where I’d say I lost respect for Nikon’s marketing department, but that would be silly since I have no respect for any marketing department. Here’s a quick tour as we rotate around the inside of the lens.

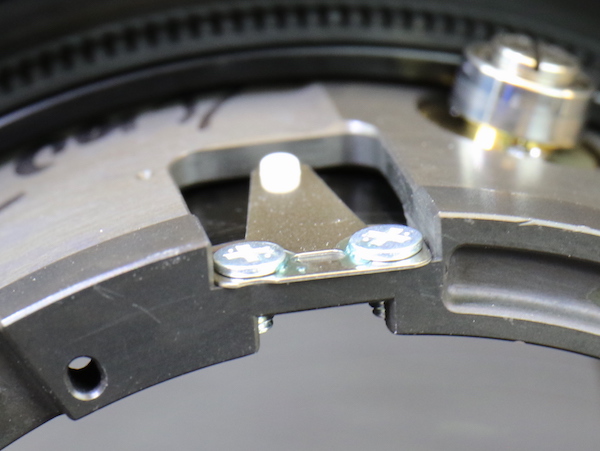

First is the GMR unit (the silver thingie held on with two screws), which is pretty much like every other GMR unit. If you take a lens apart and see this, don’t touch it, don’t breathe on it, don’t even stare at it for very long. It’s the lens repair version of crossing the streams.

Lensrentals.com, 2016

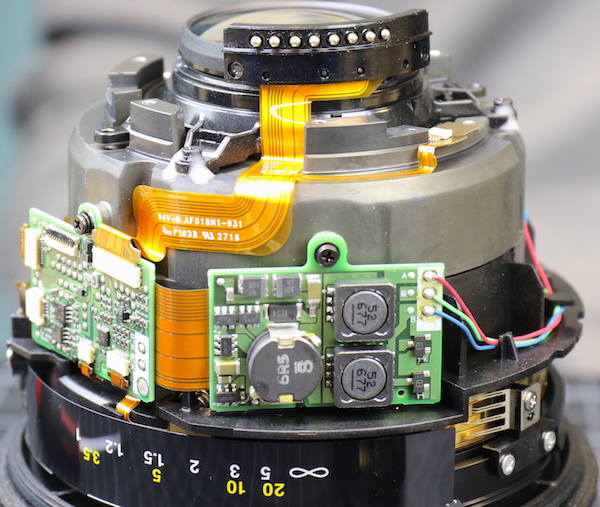

Rotating the lens just a bit we get to see those nice, chunky, flat, old-fashioned circuit boards Nikon loves to use; and yes, the soldered wires. Look, these work just fine, apparently, since Nikon has been using them since about 1965. It’s like my mom’s pink wired wall phone in her kitchen – it works great, so why change? At least they don’t run hither and yon; there are some nice plastic clips holding the wires in place. Sorry, I’m just bitter because I lost my bet with Aaron.

Lensrentals.com, 2016

Looking at the other side of the lens we see wires and flexes are held in place with Kapton tape, as is traditional with Nikon lenses. This doesn’t amount to anything as far as how the lens functions. But I’m a geek, which is why I like taking things apart, and the geek appeal here is low.

Lensrentals.com, 2016

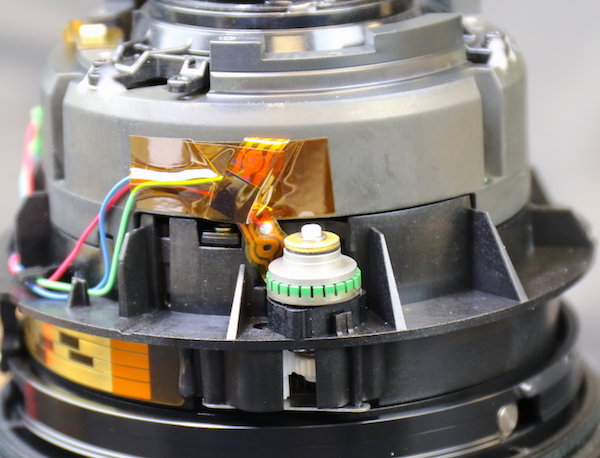

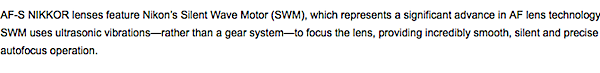

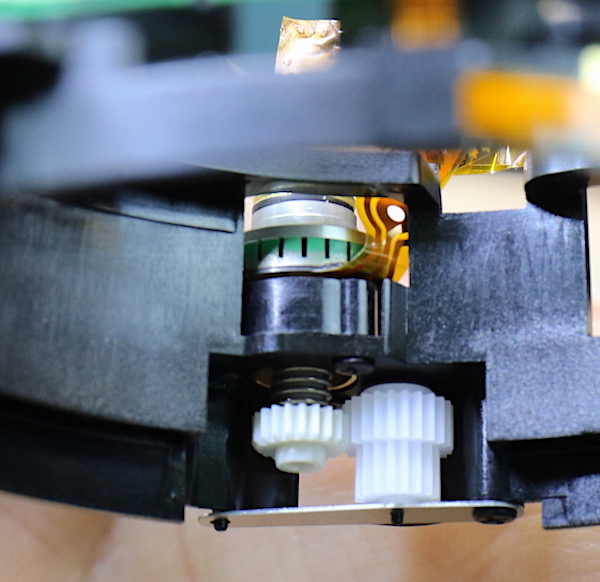

This view also exposes Nikon’s ongoing creative marketing. Many of you probably think the designation of SWM on this lens, which stands for Silent Wave Motor, means you get an expensive ring ultrasonic motor. Not so much. That’s the focusing motor there with the green band around it. Fanboys are going to scream that I’m splitting hairs trashing Nikon’s marketing about SWM, since this is technically an ultrasonic motor (although other manufacturers have the decency to call them micro-ultrasonic to differentiate them from ring-ultrasonic). Let’s look at a screen grab from the Nikon page for the 105mm f/1.4E ED AF-S lens:

http://www.nikonusa.com/en/nikon-products/product/camera-lenses/af-s-nikkor-105mm-f%252f1.4e-ed.html

Note Nikon’s text says “–rather than a gear system–to focus the lens”. If you look at the motor, what do you see? Correct. A gear system to focus the lens. The lens still focuses just fine and while it’s not silent, it is very quiet. But please don’t tell me it’s “better than a lens with a gear system” when it has a gear system, OK? Y’all must think nobody’s ever going to open up your lenses and see you’re blowing smoke up our internet.

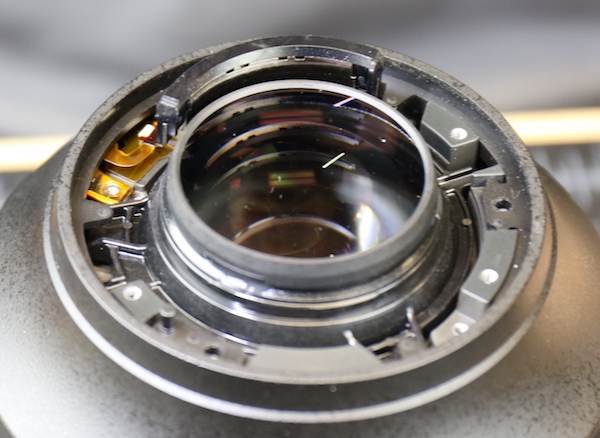

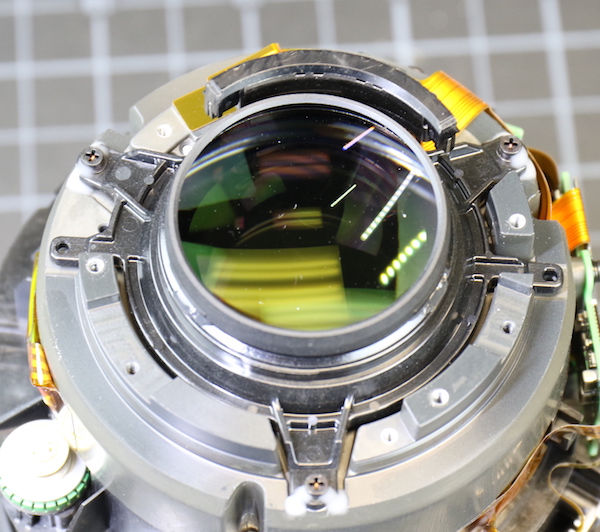

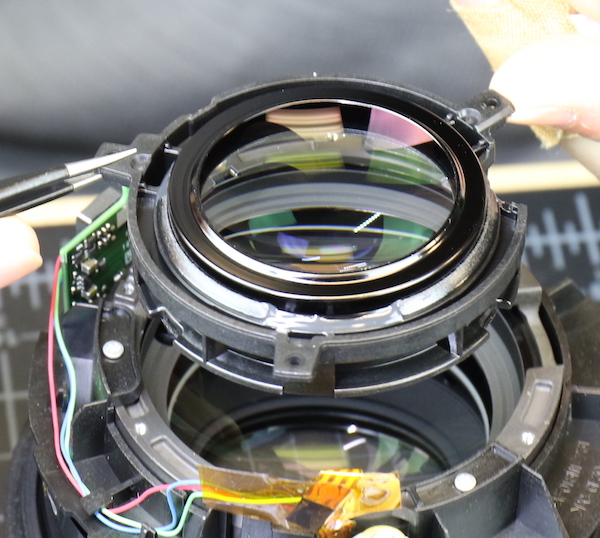

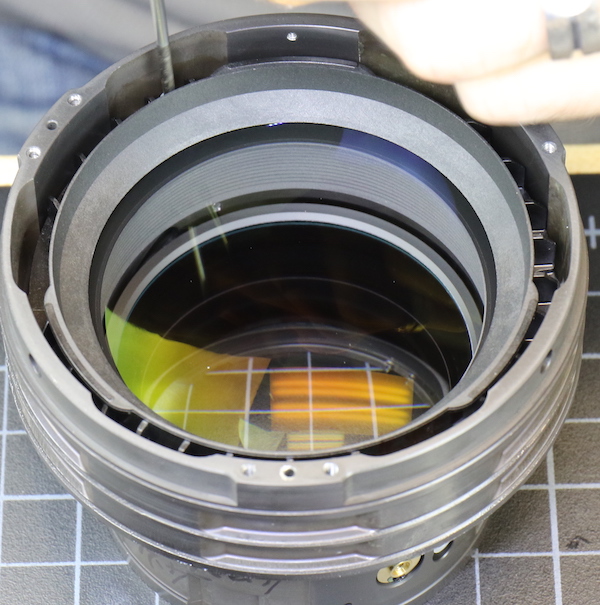

OK, now that I’ve calmed down we’ll take a look at that rear group from above. (Remember, part of why we’re here was to get the dust out of the rear group.) The rear group is in a housing that mounts to the lens on three arms at 10, 2, and 6 o’clock.

Lensrentals.com, 2016

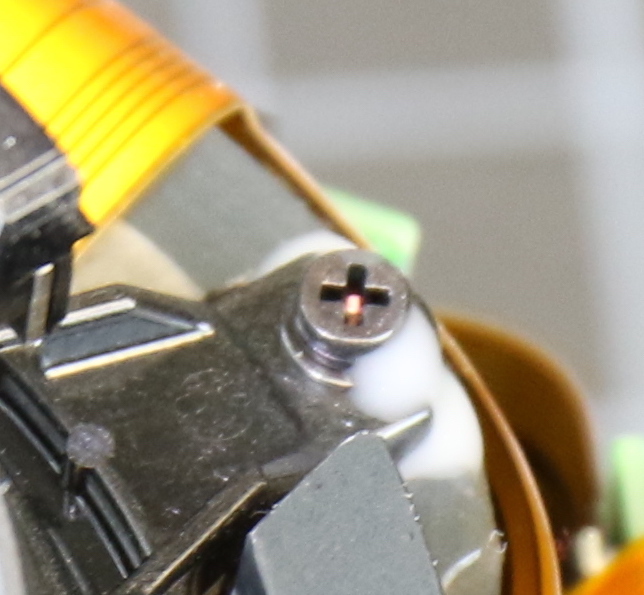

Each arm is held in place with a screw and then covered with white glue. Looking closely showed the legs were shimmed and that this is also a centering element.

Lensrentals.com, 2016

Now we don’t mind recentering an element or correcting its tilt, but when the manufacturer goes to the trouble of glueing the screws in place, and the optics are fine, we tend to go with the ‘if it ain’t broke, don’t fix it’ principle, which is what we did here.

The very rear element in this group appears to be held down by a screw-on locking ring, but again it was heavily glued, so we left it alone. (The dust you see in the picture is on the surface of that element, not inside. The dust inside was minor enough that we decided it could stay rather than ungluing and recentering everything.)

Lensrentals.com, 2016

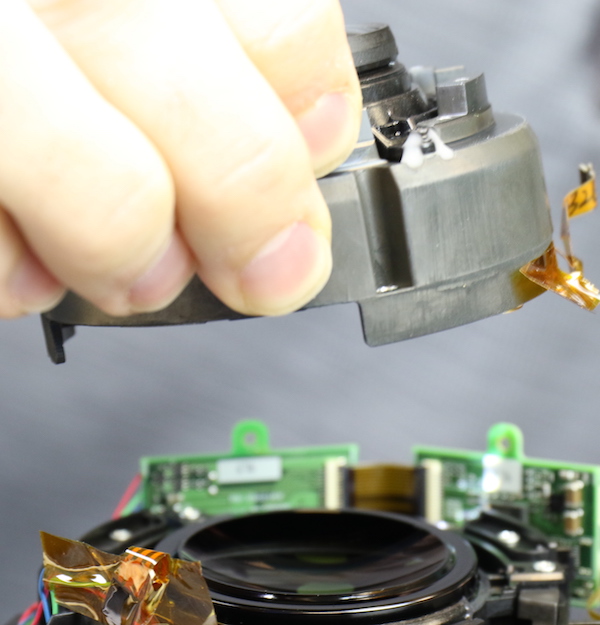

Since we decided to leave the rear group alone, we took off the rear assembly in one piece.

Lensrentals.com, 2016

Other than the glass elements we described above, this assembly contains the diaphragm unit and flexes connecting the electrical contacts to the rest of the lens.

Lensrentals.com, 2016

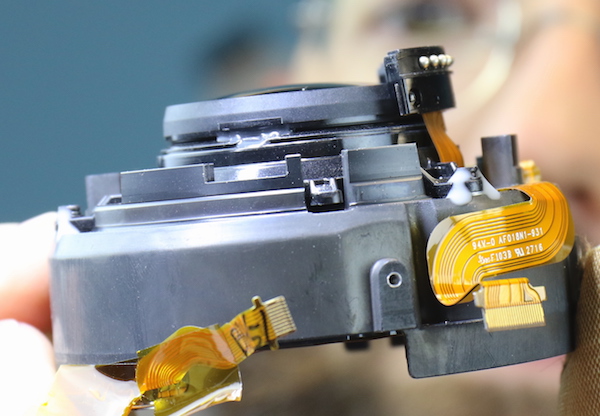

With that assembly out of the way, we’re looking at the next element. It’s also held in a plastic mount with three arms screwed into the mid barrel, but this time it’s neither a centering or a shimmed element, so it’s coming out.

Lensrentals.com, 2016

It’s a pretty impressive chunk of glass,

Lensrentals.com, 2016

rather thick and strongly curved.

Lensrentals.com, 2016

Looking back in the rear of the barrel, we can now see the focusing group down inside the motor ring.

Lensrentals.com, 2016

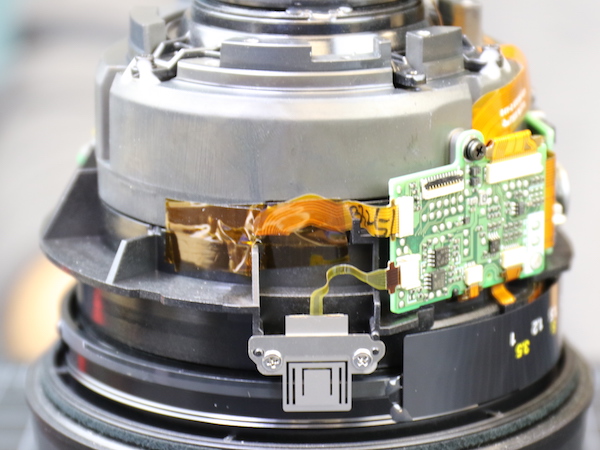

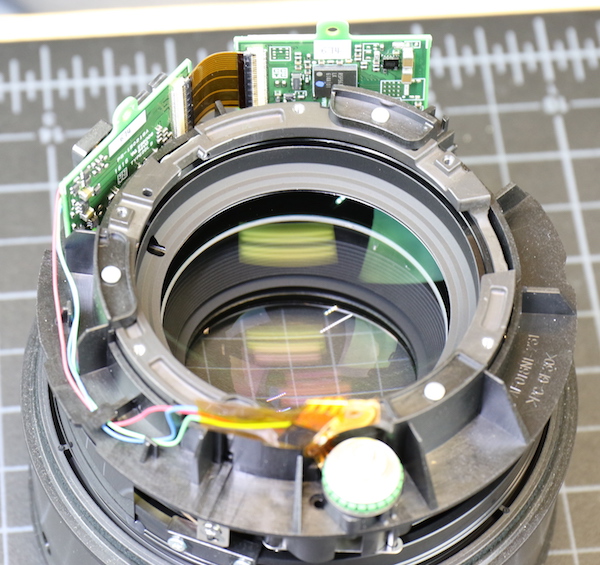

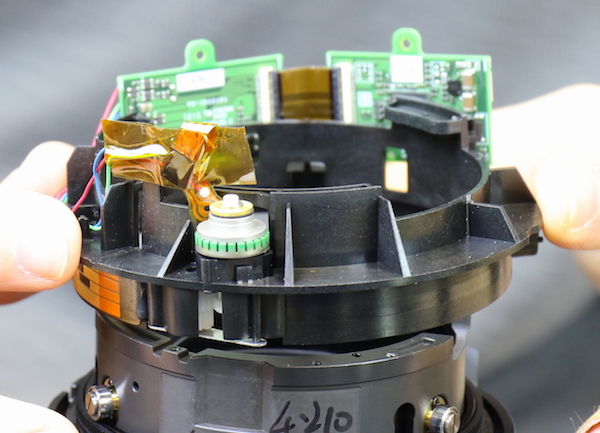

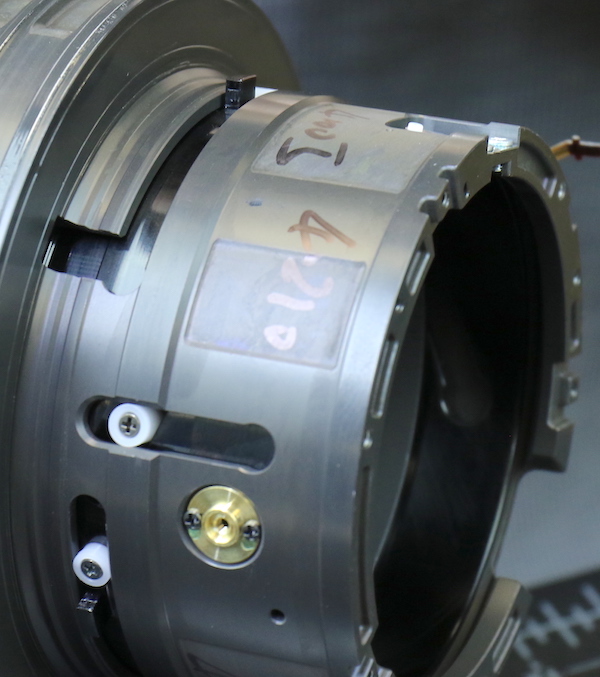

This motor ring comes off easily as a single unit. I made fun of Nikon’s old-fashioned electrics and mechanics earlier, but they’ve designed a much more modular and simple disassembly with this lens than most of their older lenses.

Lensrentals.com, 2016

As long as the motor ring is off, I’ll go back to my natural sarcastic state, and we’ll take another look at that Silent Wave Motor that’s ‘better than one with a gear system.’

Lensrentals.com, 2016

My snarky comments are reserved for the marketing department. The engineers did a very nice job making the focusing system in this lens work quite well. The gears I showed above are flexible nylon-like material, so they’re quiet. The focus rollers you see below are large, heavy duty, and secured into large brass inserts.

Lensrentals.com, 2016

There’s even a nice tensioner to keep even pressure on the focusing ring, so it has smooth, mild resistance.

Lensrentals.com, 2016

Next, we turned our attention to the front of the lens. The filter barrel removes easily after taking out three screws reached through slots in the focus ring. Again, there is thick felt sealing where the filter barrel joins the focus barrel.

Lensrentals.com, 2016

Removing a set of thick screws and inserts lets us then slide the focus barrel assembly off of the back of the lens.

Lensrentals.com, 2016

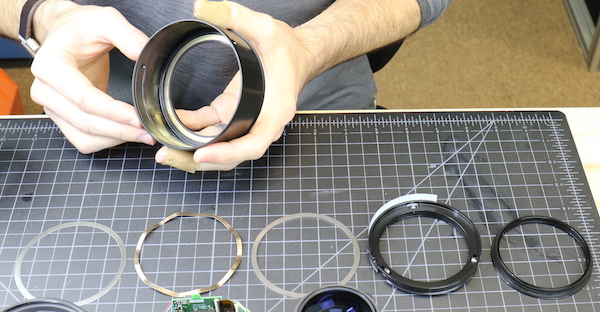

The focus barrel assembly is quite complex, and again we get to see some careful, thoughtful engineering goes in to making the focus movement so smooth and constant on this lens. Once it’s removed a nest of rings comes out of the barrel.

Lensrentals.com, 2016

Laid out you see there are two smooth friction rings with a ring tensioning spring between them, the distance scale ring, and on the far right the geared ring that the focusing motor gear train actually turns.

Lensrentals.com, 2016

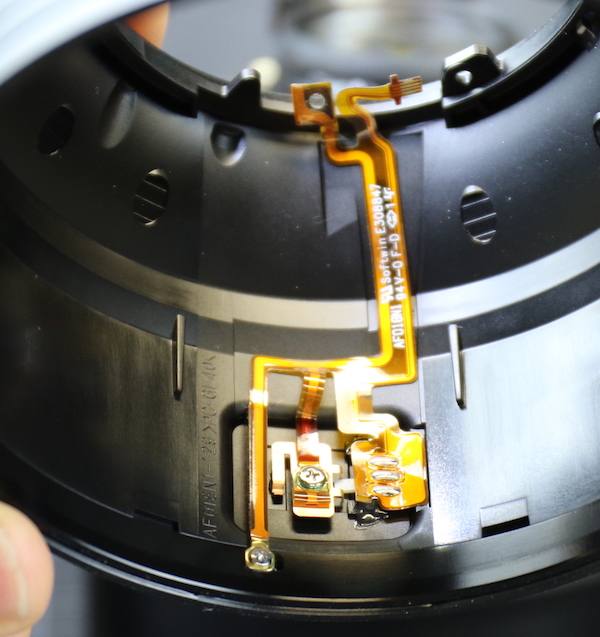

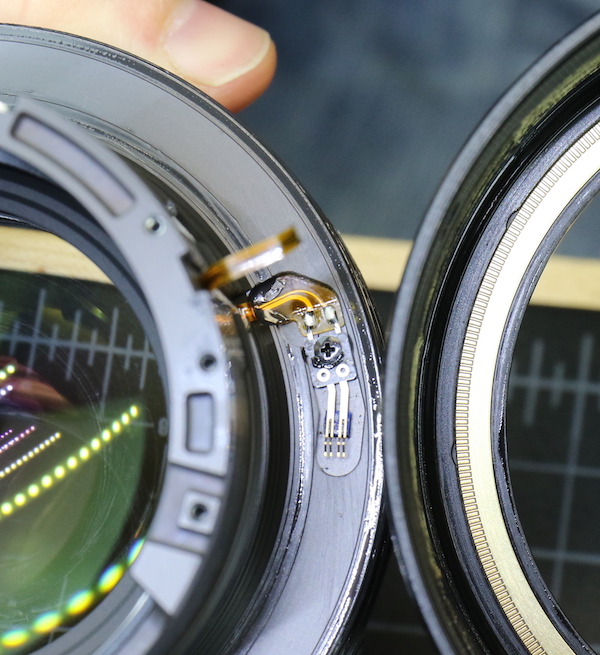

Inside the focusing ring is an electronic sensor that goes over a brush assembly on the lens barrel. This isn’t an absolute position sensor; it seems to measure rate and distance turning of the focus ring.

Lensrentals.com, 2016

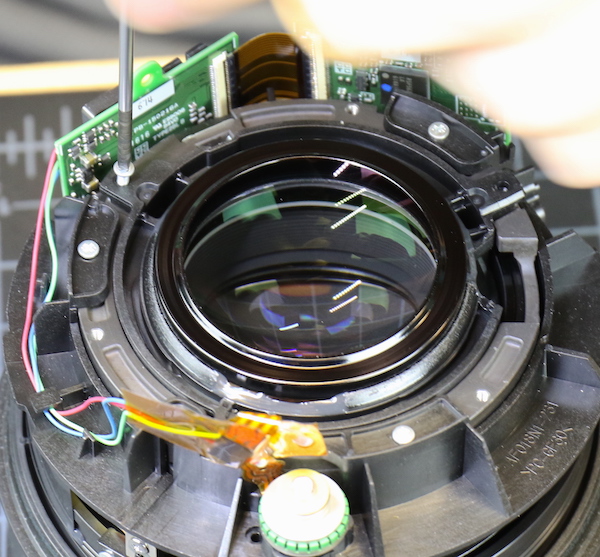

With the filter barrel off, we can take a look at the actual optical focusing mechanism. In this lens, the focusing group has a very long travel which should allow very precise focusing; a good thing with a wide-aperture 105mm lens. The two images below show the movement at the two focusing extremes.

Lensrentals.com, 2016

Lensrentals.com, 2016

Finally, we turned our attention to the front group. Remember getting dust out from under the front element was another excuse for this exercise. The front element is held in place by three pairs of screws. There’s no centering here, but there are shims under each pair of screws so this element is adjusted for spacing, or perhaps spacing and tilt.

Lensrentals.com, 2016

It came off quickly enough, and when we examined the shims they were of different thickness, so both spacing and tilt are being adjusted here. For this particular copy, it wasn’t a big tilt, with a thickness ranging from 0.4mm to 0.44mm.

Lensrentals.com, 2016

The bad news for us is the dust we saw isn’t under the front element, it is within that front group of two elements, which is sealed. For those of you with enquiring minds, it probably is not environmental dust, but a crumbled piece of cement within the group, so the group will have to be replaced. If this were my personal lens, of course, I’d leave it alone, but it’s a rental, and someone will lose their mind when they see a dust flake in their rental lens.

Since we’d come this far, we went ahead and took out the second group.

Lensrentals.com, 2016

With the second group removed, are left with just the focusing element in the lens barrel.

Lensrentals.com, 2016

Because everyone asks, yes we put it back together. Yes, it works perfectly fine and is optically unchanged. And since we can’t buy replacement front groups we’ll have to send it to the Service Center to get the front group replaced. The smaller amount of dust in the rear group could probably have been removed but would have required optical readjustment after it was done. Since it’s going to the service center anyway, we’ll see if they’ll take care of that too.

Impressions

I always hope to see engineering elegance in a disassembled lens, and this lens has some of that. The construction is very solid. There are heavy duty rollers, cams, and bearings and the standard ‘polycarbonate shell over metal core’ construction that most high-quality lenses have theses days. The care taken to engineer a smooth, accurate focusing feel is very evident. The weather resistant seals are thorough, even if not dramatically over-engineered. (If you consider asking if it is weatherproof, I will, of course, refer you to the warranty which reads ‘void for moisture damage’).

There is some engineering lack of elegance, too. I poke a little fun at the solders, wires, and tape that we only see in Nikon lenses these days, but they work just fine, and the end result is good. The throwback lens construction is becoming kind of endearing to me, in a nostalgic kind of way. There’s not a real downside to it that I can tell; Nikon lenses are just as reliable as anyone else’s.

While I’m never surprised when a new lens gets some dust in it early on, I’m disappointed that it’s occurring in sealed elements in this lens and will require element replacement. But this is just one copy; that doesn’t mean it’s going to be an ongoing problem. It might. It might not. Time will tell. Since few of you are ever going to clean dust out of your lenses it probably won’t matter to you at all.

The focus motor marketing bothers me a lot, although I realize it won’t bother many of you. I’ve long been sick of marketing departments hiding all facts and telling me to trust them, this new lens will make me a dramatically better photographer. But in this case, they’re pretty dishonest in telling me this lens has an advantage because it has a gearless system when it actually has a geared system.

Does it make the Nikon 105mm f/1.4E ED anything other than a great lens? Nope, it’s a great lens and solidly constructed. Its focusing system is still excellent and accurate, no matter what kind of motor is driving it. It’s just my personal battle, charging the cloudy darkness created by the giant windmills of marketing.

Roger Cicala and Aaron Closz

Lensrentals.com

December, 2016

Addendum: about 24 hours after this post was referenced by DP Review, Nikon changed the wording describing the SWM motor in this lens, removing any reference to gears. Their description is factually correct now.

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Photographer100

-

Photographer100

-

Photographer100

-

Photographer100

-

nononononono

-

Kaouthia

-

fanboy fagz

-

Roger Cicala

-

Roger Cicala

-

fanboy fagz

-

John Koerner

-

Kaouthia

-

Astro Landscapes

-

Astro Landscapes

-

Astro Landscapes

-

King of Swaziland

-

Photographer100

-

revaaron

-

akkual

-

akkual

-

akkual

-

Omesh Singh

-

johann jensson

-

Roger Cicala

-

Gearsau

-

thxforinsults

-

TwoStrayCats

-

nonono

-

chrisgull

-

nonono