Equipment

Taking Apart the Zeiss 85mm T2.1 CP.3 Cinema Lens

Lensrentlas.com, 2017

Long ago, in an office far, far away we did a teardown of the Zeiss 85mm CP.2 lens. Since we’ve already seen the earlier model, we thought it would be interesting to take a peek inside the new Zeiss 85mm CP.3 lens as well. We’re going to have to work on them eventually, and it’s always good to have an idea what we’ll be getting ourselves into.

If we understand correctly, most of the CP.3 and CP.2 are optically identical, the exception being the 18mm focal length (although Zeiss isn’t saying directly). The housings are improved on the CP.3 lenses, and that’s what we were interested in looking at. If you want to make a more direct comparison, you can open the Zeiss CP.2 teardown in a separate window. I’ll try to roughly follow the same order.

Lensrentals.com, 2017

NOTE: I have linked to some images from the CP.2 teardown to make comparisons easier. If you click on these links, the image pops up but has the title of this article at the bottom. Just realize the pop-up images are of the Zeiss CP.2 version.

We start by taking off the front light baffle.

Lensrentals.com, 2017

On the CP.2 this is one piece, but the CP.3 separates the spanner ring

Lensrentals.com, 2017

from the light baffle

Lensrentals.com, 2017

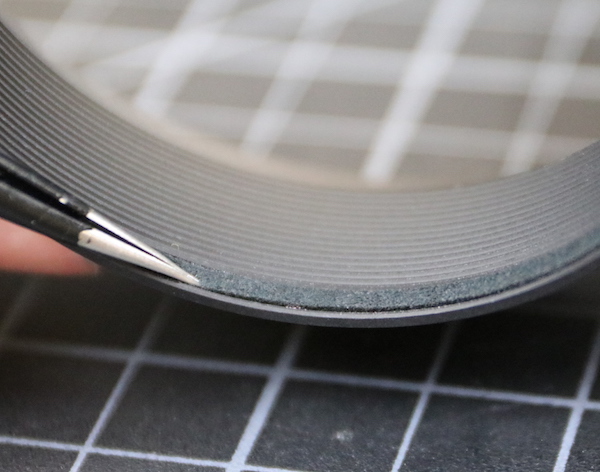

The lower side of the baffle has a thick felt seal where it seats against the front element of the lens like you’d expect.

Lensrentals.com, 2017

With the baffle removed we can see that the front group arrangement is very similar to the Zeiss CP.2 Version; the group is set on a centering plate held down by four screws. You can make out, at the bottom of the barrel, the nylon helicoid that’s part of the focusing system.

Lensrentals.com, 2017

The smaller size of the CP.3 makes it a bit more difficult to get to the screws. We had to try a couple of different drivers to get a barrel narrow enough to fit easily.

Lensrentals.com, 2017

Lensrentals.com, 2017

Once it’s out, you can see it’s basically identical to the front group of the 85mm CP.2.

Lensrentals.com, 2017

With the front optical group removed, we get a look down at the oh-so-nice aperture assembly.

Lensrentals.com, 2017

The next step is to remove the blue rubber makeup ring and the nylon seal below it, exactly what we do on the CP.2 lenses.

Lensrentals.com, 2017

This gives us access to the screws that hold the focus ring on. The slots are so the ring can be adjusted to make readings accurate, of course.

Lensrentals.com, 2017

Removing those screws lets us slide the ring off.

Lensrentals.com, 2017

Underneath are a couple more rubber weather seals (the red lines you see are actually thin rings). Also, the adjustable silver bar is the infinity hard stop for the focusing assembly. This is quite different than the mechanism in the CP.2 and this seems much easier to adjust.

Now it’s time to open up the back half of the lens. The interchangeable mount comes off in the usual fashion.

Lensrentals.com, 2017

As does the lens mount underneath it.

Lensrentals.com, 2017

The focus-distance shims are underneath this ring. This is a routine way of doing things, used in the CP.2 and many other Cine lenses.

Lensrentals.com, 2017

At this point we can show you where the electronic connections will be for the eXtended data versions of the CP.3, coming up from the lens body (which has a sealing plug in this non XD version) . . .

Lensrentals.com, 2017

. . . and, at least on this mount, tucked away for protection. Some XD mount versions will communicate through this piece to electrodes at the lens mount, some versions through a Lemo port rather than the mount.

Lensrentals.com, 2017

Just as it is in the CP.2 version, the rear group is held in place by a spanner ring. It is non-centering, only the front group is adjustable for centering.

Lensrentals.com, 2017

But there is a shim to adjust spacing under the rear group.

Lensrentals.com, 2017

Next we span off the aperture-pressure retainer ring after dissolving the glue that holds it in place.

Lensrentals.com, 2017

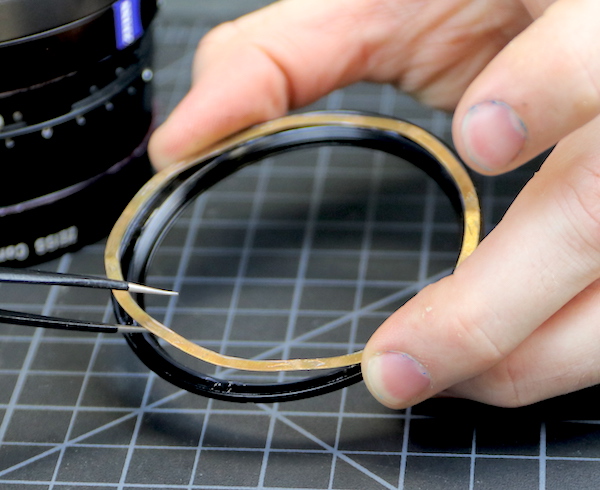

There’s a brass spring-ring underneath the spanner ring that actually provides the friction to the outer aperture ring.

Lensrentals.com, 2017

Speaking of the aperture ring, next we remove the screws that attach it to the aperture assembly.

Lensrentals.com, 2017

Then we can slide the ring off. Notice there’s another of the red rubber seals here. There’s no joint in this lens that doesn’t have a seal of some type. The little bit of white you see around the red ring is lubricant. Overall, this part of the assembly is identical, other than the shape of the parts, to what we saw in the CP.2.

Lensrentals.com, 2017

The underside of the aperture ring contains the hard stops for aperture settings. You can see two of the three screw ends that hold this in place.

Lensrentals.com, 2017

Looking at the other side of the barrel, you see the slots the screws are set into, allowing adjustment of the hard stops.

Lensrentals.com, 2017

The fixed (AKA mid) barrel is held on by six screws.

Lensrentals.com, 2017

The screw holes are set in slots. We assume this acts as a shock or vibration absorber. But we often assume wrong, so take it for what it’s worth. The CP.2 had similar slots on this barrel.

Lensrentals.com, 2017

Finally, the last piece of outer barrel, the front filter ring, is removed. This could have been done earlier, the order wasn’t critical.

Lensrentals.com, 2017

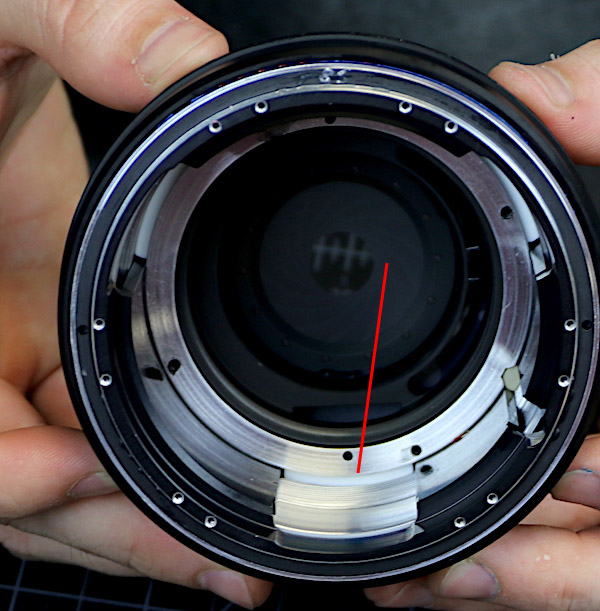

Looking at the inner assembly of the lens, there’s a very obvious large, white nylon piece that is a new addition compared to the CP.2 lenses.

Lensrentals.com, 2017

Looking inside the barrel, we can see that helicoid assembly is nylon on aluminum threading.

Lensrentals.com, 2017

Lensrentals.com, 2017

This should be smoother and more shock absorbing than metal on metal of the CP.2, but only time will tell how it holds up. It could be more robust, maybe not. But CP lenses have a very reliable track record under a fair amount of abuse so my guess is these will be very reliable, too. This is probably why Zeiss claims the focusing system will function better at temperature extremes; nylon isn’t going to expand or bind at temperature extremes.

There was one more area we wanted to explore. There was a spanner ring on the top of the inner focusing barrel that was crying ‘take me off, take me off’, so we did.

Lensrentals.com, 2017

Lensrentals.com, 2017

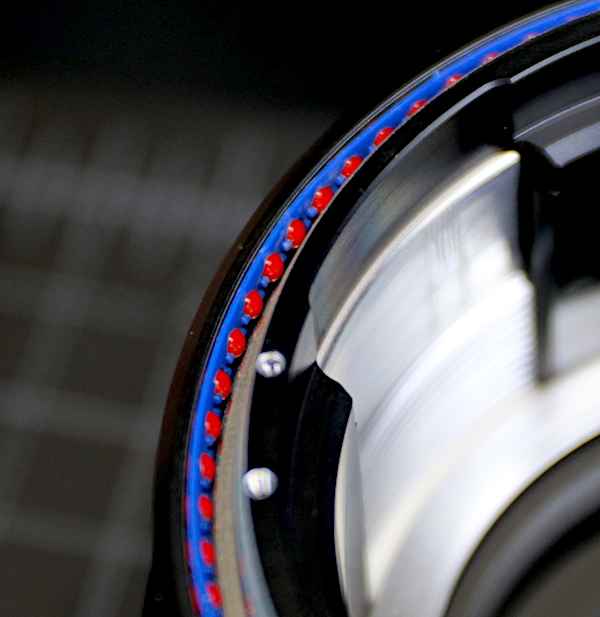

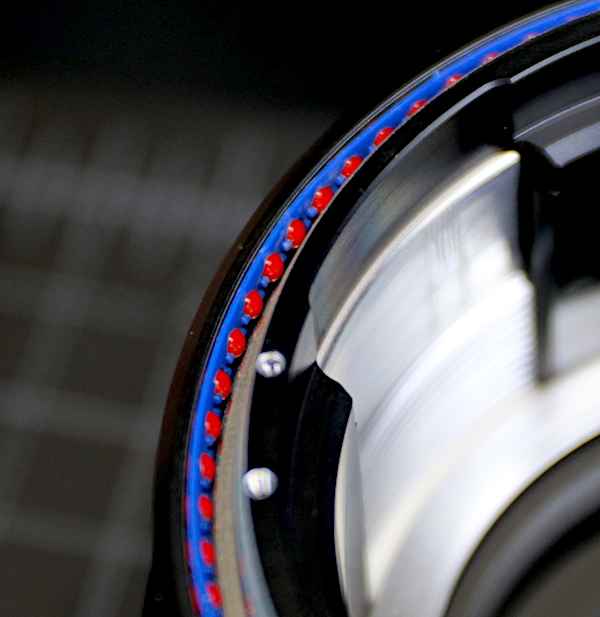

Underneath, in a most unZeissly bright color scheme, was a strip of neon blue plastic inset with bright orange plastic ball bearings.

Lensrentals.com, 2017

It took us a moment to regroup from this splash of color in a Zeiss lens. (Well, it took me a moment. Aaron is color blind so a lot of the impact was lost for him.) It was sort of like finding out the guy who always wears grey Armani pinstripe suits favors polka-dot boxers. But after a moment the purpose of this became apparent.

The spanner ring has a beveled inner lip…

Lensrentals.com, 2017

as the ring is tightened down this pushes the ball bearing strip against the inner focusing ring, providing a way to adjust the resistance while keeping it very smooth.

Lensrentlas.com, 2017

It’s kind of an elegant solution compared to the usual spring loaded rollers or bumpers used for that purpose.

So What Did We Learn Today?

Well, the Zeiss CP.3 85mm T2.1 is optically identical to the Zeiss 85mm CP.2, but in a new housing. The housing has some nice new touches, and a splash of color you’ll (hopefully) never see except in the pages of this blog. It’s a bit more compact externally than the CP.2, which will be an advantage for some people.

The increased use of nylon and plastic in the focusing and aperture accounts for the smoother focusing we felt when using the lens. It probably has a lot to do with the improvement of focusing and aperture at extreme temperatures that Zeiss claims for the CP.3 lenses. Whether it has a positive or adverse effect on long-term reliability, I can’t begin to guess.

For those of you who collect the whole set, the physical consistency between the different focal lengths in the CP.2 lenses will certainly be advantageous. If you work at extreme temperatures, there’s a distinct advantage to the CP.3, too. Of course, many of you are eagerly awaiting the eXtended Data versions. But if you currently have CP.2 lenses and are happy with how they focus there’s not a huge reason to run out and upgrade to the non-ED CP.3.

Roger Cicala and Aaron Closz

Lensrentals.com

August, 2017

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Dan Lim

-

Alex Toney

-

asad137

-

Chuck

-

Simeon Boys-Layton

-

Brandon Dube

-

SpecialMan

-

Lee

-

Roger Cicala

-

Roger Cicala

-

Lee

-

asad137

-

Roger Cicala

-

Roger Cicala

-

Horst

-

J L Williams

-

David Weber