Equipment

Disassembling the Sony FE 135mm f/1.8 GM

When we optically tested the Sony FE 135mm f/1.8 GM we were mighty impressed. Then I threw up in my mouth a little when I read a couple of reviewers comment on the build quality. Because holding a lens gives you not the slightest idea about the build quality. So I was excited when a 135mm went out and failed on rental. Sorry for the customer, of course, but since parts aren’t readily available yet, it allowed us to look inside and see if we could figure out the problem. And did I mention, look inside?

We suspected we knew what the problem was, at least generally. This lens had performed flawlessly, then suddenly gotten horribly soft in the middle of the shoot; so soft that the camera struggled to autofocus. A quick optical test when it got back showed resolution was almost nil. In our experience, this means one of the elements is out of place.

So Get Out Your Screwdrivers and Follow Along at Home!

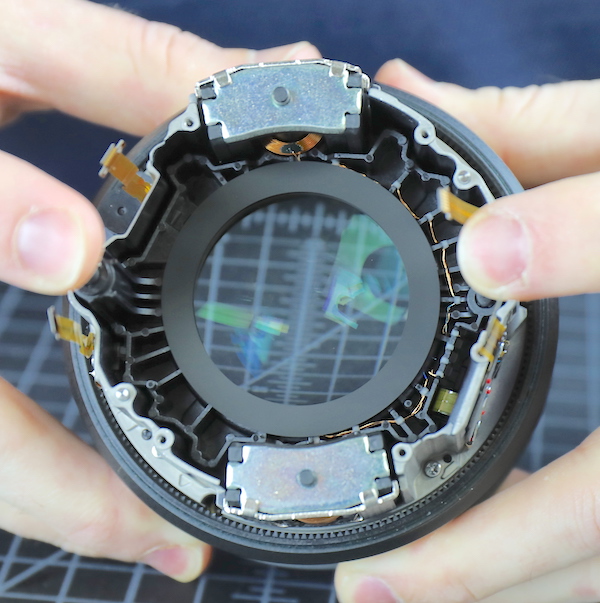

We looked at things for a while, deciding whether to go in from the front or the back; we don’t have any repair manuals for this new lens. It is pretty, though, isn’t it?

After a coin toss, we decided on front. So the focus ring rubber was removed, and we started peeling back the sealing tape underneath it.

Lensrentals.com, 2019

With the tape off we can see three white plastic inserts in the barrel. These are probably sliders or tensioners to give the focusing ring that ‘manual focus’ feel.

Lensrentals.com, 2019

There are also some windows and in the windows are some shims. So the front group is shimmed for spacing and possibly tilt, but that’s not accessible yet.

Lensrentals.com, 2019

There are also (when the ring is rotated to the right position) some holes. At the bottom of the holes are some screws. Probably screws holding on the filter ring.

Lensrentals.com, 2019

With the screws removed, a 1/8 turn of the filter ring lets it slide off. This is good engineering in two ways. First, a dented filter ring should be an easy and cheap replacement. Second, the 1/8 turn means it’s held on not just by screws, but also by slots within the ring.

Lensrentals.com, 2019

So good news and bad news. The good news is there’s a nice, thick weather sealing gasket under the filter ring. The bad news is there’s nothing else accessible there, so ‘open the front’ was a bad choice.

Lensrentals.com, 2019

So the filter ring goes back on, the lens gets flipped over, and we start going in from the back. Hopefully, we can get in from the back because going in from the side never has never worked well.

Lensrentals.com, 2019

As the bayonet mount comes off, we see the usual weather sealing around the edges and some shims underneath. You can also see a second area of foam on the rear barrel where it would seal against the inside of the bayonet. This is good weather sealing, but before you get all excited, Sony fans, I’ll go on record as saying early returns on multiple copies indicate this lens gets dusty inside pretty quick. We’ve already had to dust several, and they haven’t been in stock that long.

Lensrentals.com, 2019

The shims are of different thicknesses, and it’s obvious they can be placed at any quadrant, so these are for tilt as well as possibly spacing.

Lensrentals.com, 2019

The PCB in this lens is held under the rear barrel, so the barrel has to come off before the PCB does.

Lesnrentals.com, 2019

Removing five screws and disconnecting the switch flex lets us slide the outer barrel off.

Lesnrentals.com, 2019

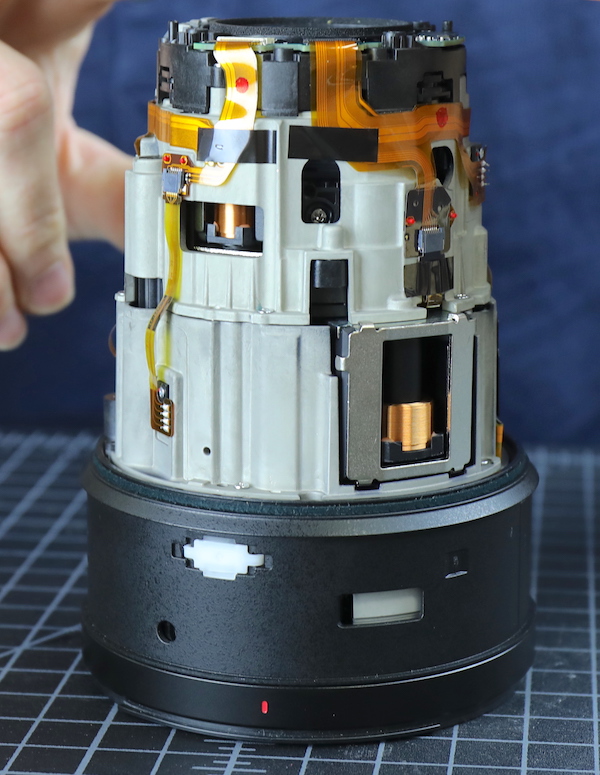

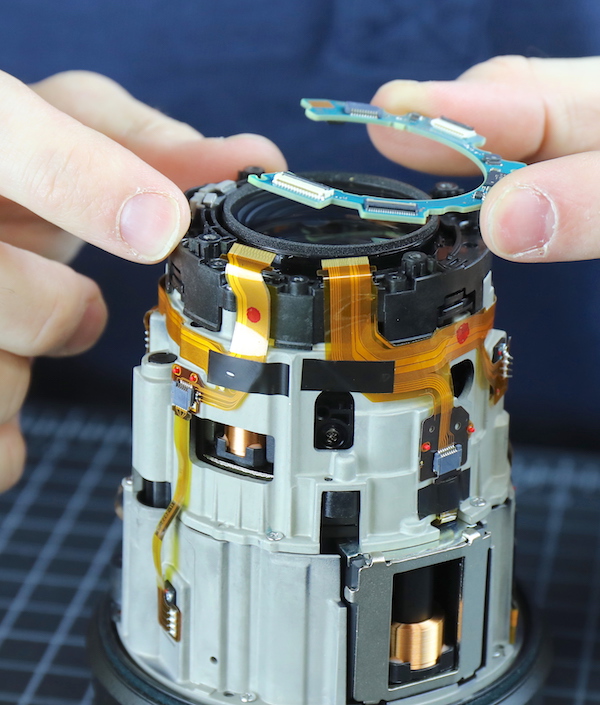

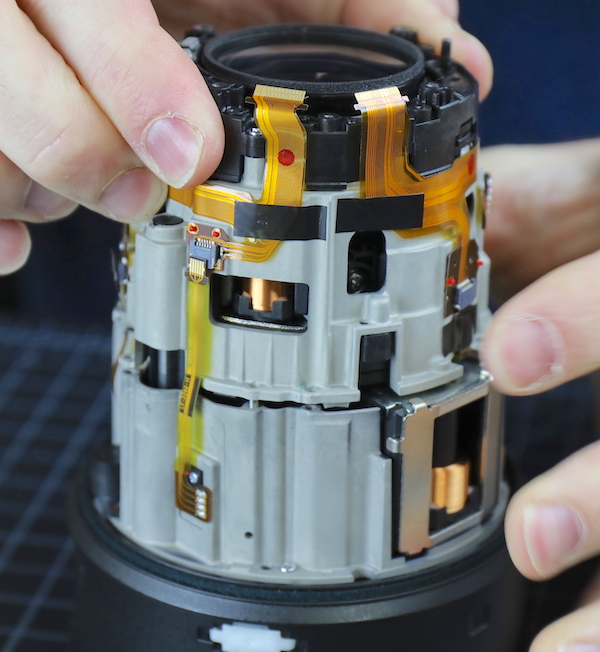

Exposing the inner barrel in all its magnesium-alloy glory. Note to shade-tree reviewers out there: if you haven’t seen the inner barrel then don’t comment on build quality. It shows that you’re guessing and makes people wonder what else you’re speculating about.

Lesnrentals.com, 2019

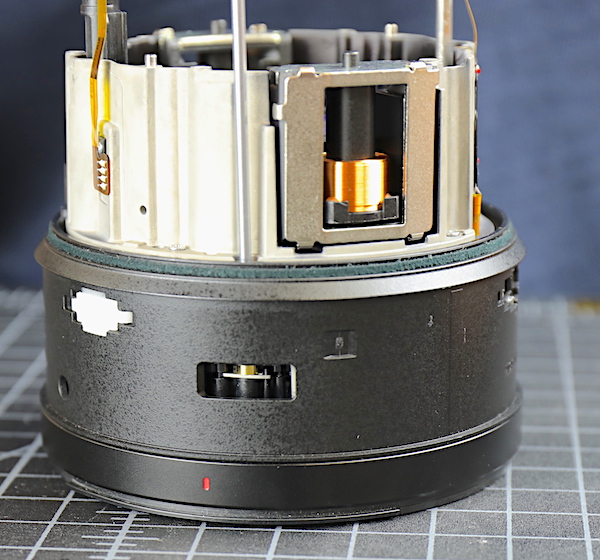

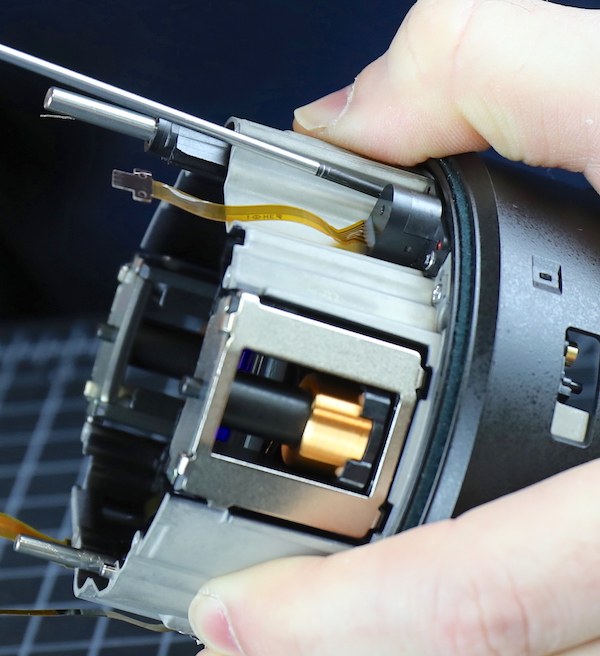

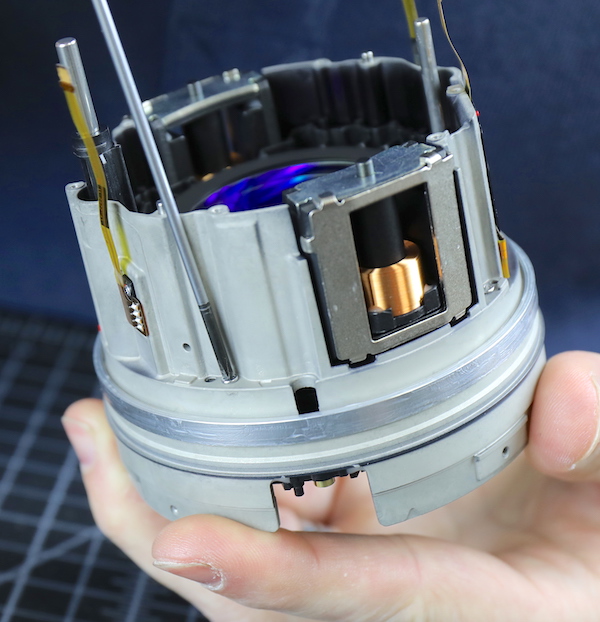

This gives a nice view of the coils for the two focusing motors; smaller rear and larger front. As always, we appreciate designers who take the time to lay out nice, neat flex runs. It makes things look like there was great attention given to detail. Things are laid out logically and modularly, and the build quality is robust. It looks like a small super-telephoto inside.

It’s really impressive that both focusing groups have a really long travel distance. While I can’t say for sure, logically this should allow very accurate focus with optical groups that aren’t too strong, meaning optical groups with fewer aberrations.

Lensrentals.com, 2019

Lensrentals.com, 2019

We also see some eccentric collars on the rear focusing group for adjusting the tilt.

Lensrentals.com, 2019

One other (sort of) interesting note, under the rear mount is the standard Sony shim insertion plate at three locations, but with no shims. We don’t know if some copies need shims, although that seems redundant given the shimming under the mount. It could simply be this is a standard part used on several lenses.

Lensrentals.com, 2019

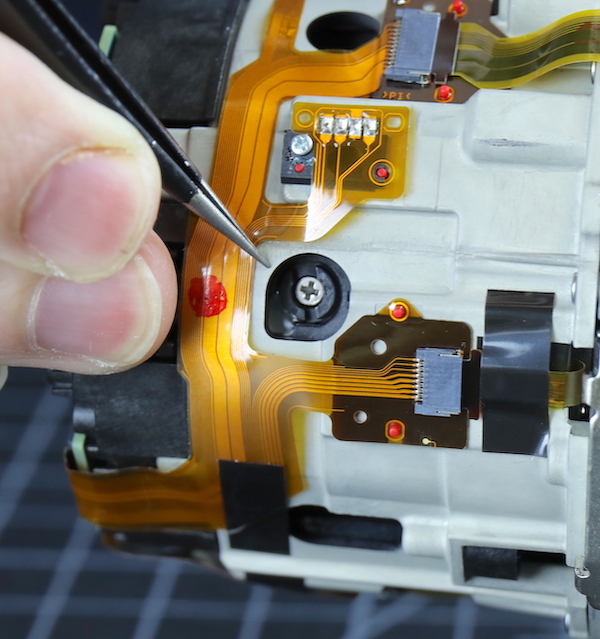

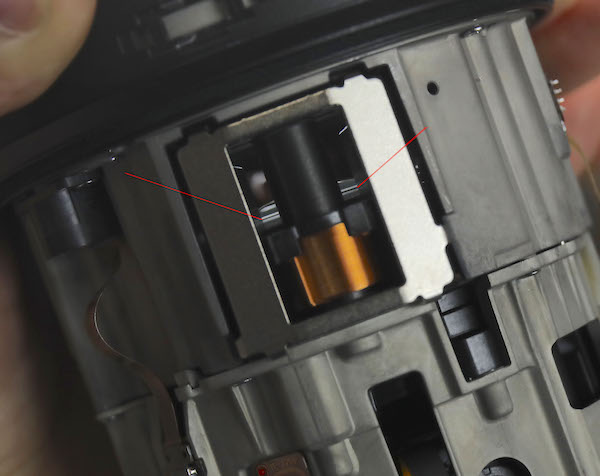

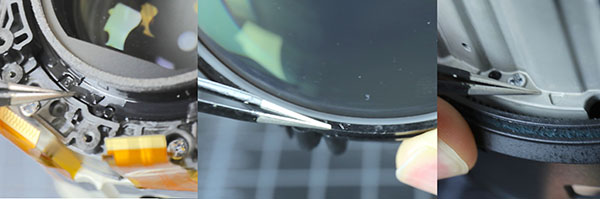

While we were peaking through slots, Aaron spotted what he thought might be the problem: the front element of the front focusing group seemed to be poking up a little bit on one side. It was hard to see and even harder to try getting a picture of, but at the red lines, you can sort of see the edge of the glass element, which you shouldn’t be able to do. More importantly, looking through the slots on the other side looks different, and that shouldn’t be.

Lensrentals.com, 2019

We’ll need to get deeper in the lens to find out if Aaron was right. (Since the editor is always yelling at me for not caring about clicks and comments, I’ll reword this. “Should we go deeper in the lens? What do you think? Comment below!!) OK, you all voted yes, so off comes the PCB.

Lensrentals.com, 2019

In case you couldn’t tell from the image above, the inner barrel has front and rear halves screwed directly together, which seems like the logical next disassembly step.

Lensrentals.com, 2019

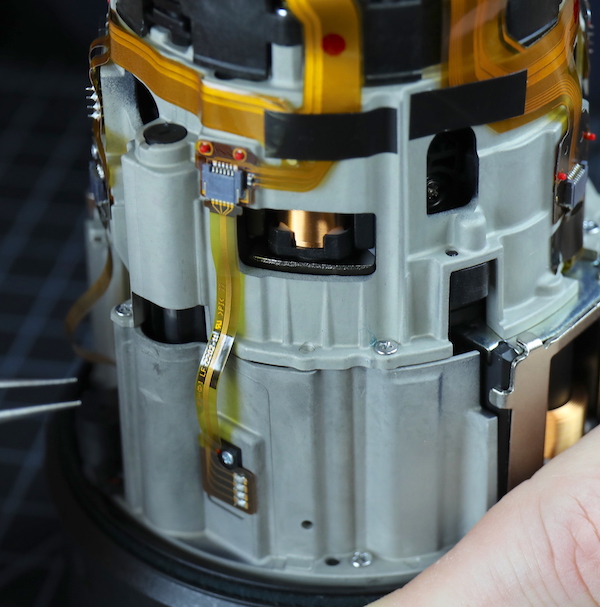

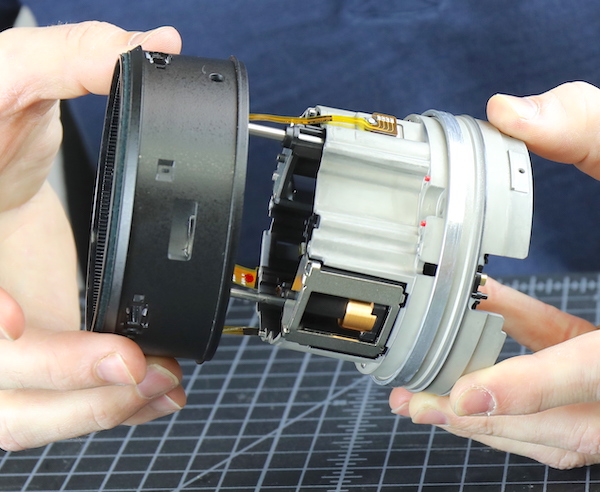

With the screws removed and the flexes disconnected, the two barrel halves separate nicely.

Lensrentals.com, 2019

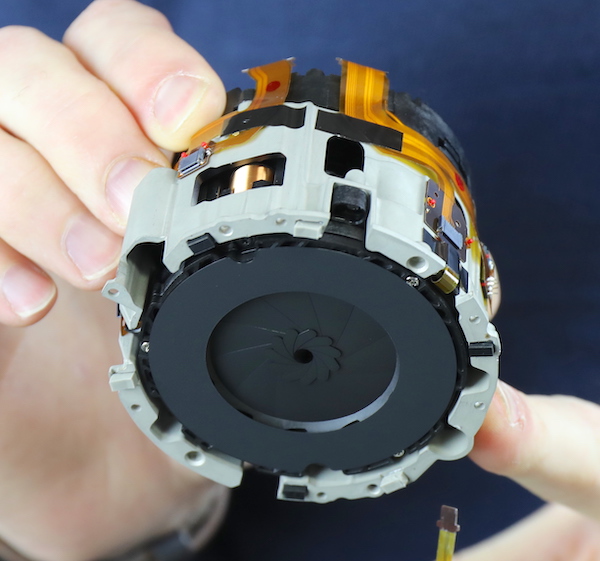

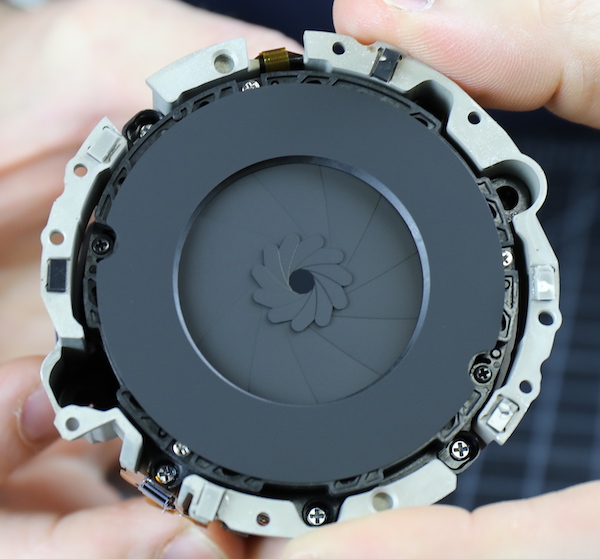

The rear half contains the rear element, rear focusing group, and aperture assembly.

Lensrentals.com, 2019

Here’s a straight-on view of the aperture; really nice and smoothly circular.

Lensrentals.com, 2019

The front half still has the focusing and filter barrels attached. There’s some more weather sealing under the barrel.

Lensrentals.com, 2019

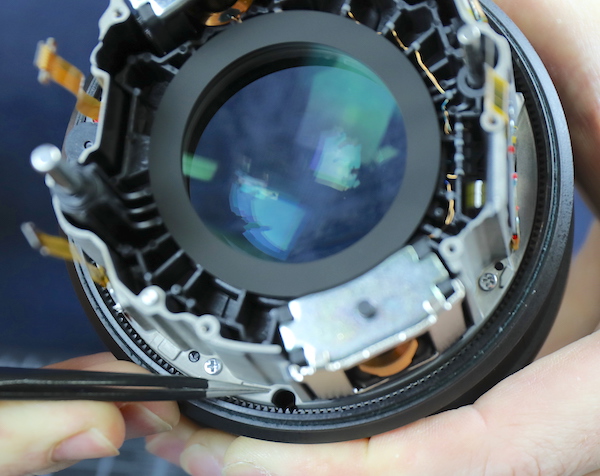

Looking down into this section from the rear, you get a good look at how big the electromagnetic motors are for this focusing group. Notice the wiring connecting the two motors running along the right side, and the geared teeth in the focusing ring.

Lensrentals.com, 2019

We showed you the travel of the focusing motor earlier, but I find it even more impressive when you see how far the focusing group is moving.

Lensrentals.com, 2019

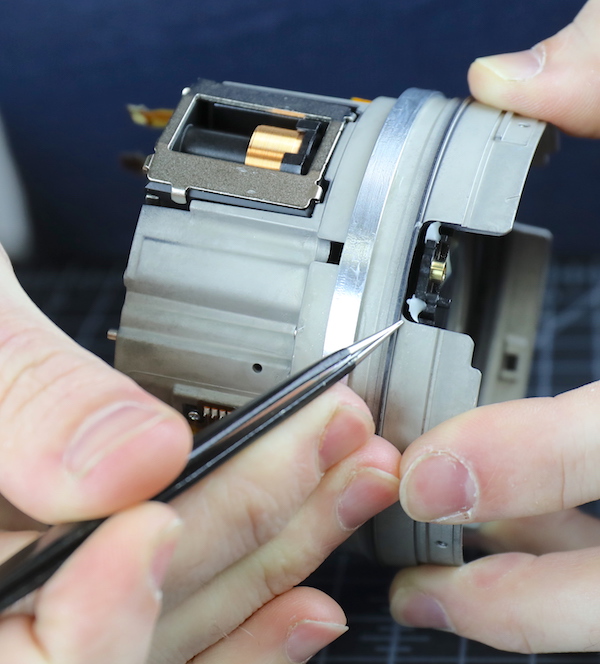

OK, back to work, we still need to get inside here and access the front of the focusing group. We had already detached the filter ring and just put it back in place for the disassembly. There are some obvious screws that could be holding the inner barrel onto the front of the lens.

Lensrentals.com, 2019

But we can’t see what’s under the focusing barrel, which makes us nervous. There are some other holes that have screws at the bottom that pass through those front element shims we showed you earlier, so we decided to take the front element before doing anything we might regret later.

Lensrentals.com, 2019

Aaron loosened the screws a bit so he could remove the shims and keep them in proper order. These three ranged in thickness from 0.48mm to 0.27mm, so there was some significant tilt being applied to the front group in this copy.

Lensrentals.com, 2019

With the shims marked and placed, the screws were removed, and the front group comes out.

Lensrentals.com, 2019

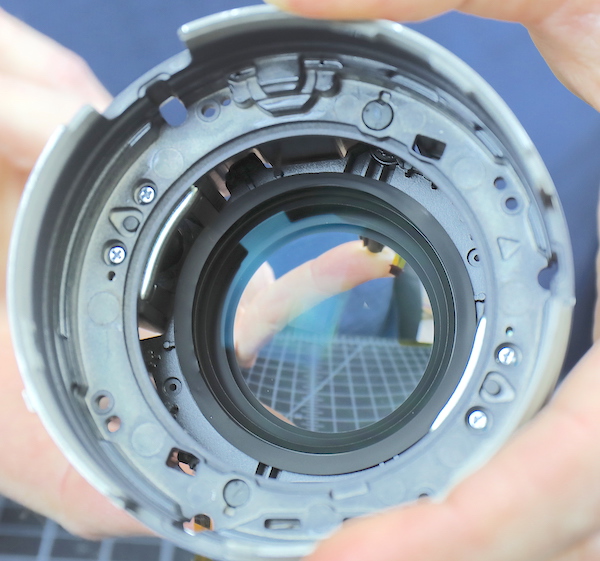

A quick aside for those who have thought, “but doesn’t each piece of glass have to go back in the way it came out, so the shims are right”? Yes, it does, and usually, we mark each part as we remove it so we can line them back up correctly. Sony has made this lens foolproof, though, and again we appreciate helpful engineering. The lens elements, barrels, almost every bit of the lens is marked on one side with small triangles. When you reassemble, just line up the triangles, and you’re good to go!

Lensrentals.com, 2019

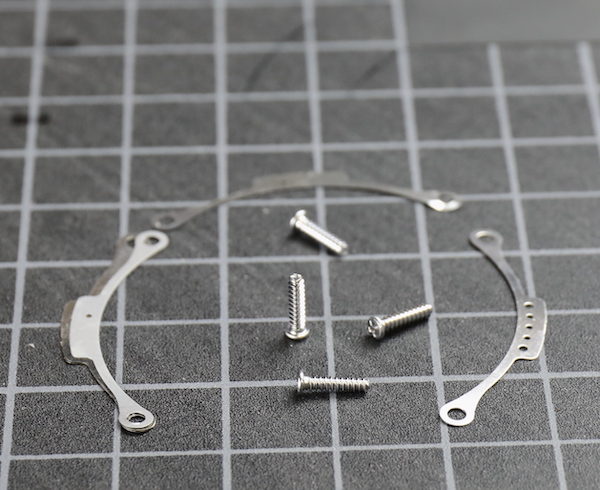

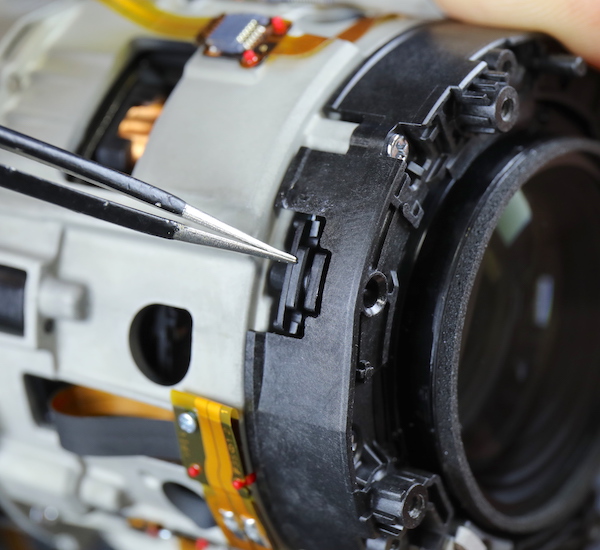

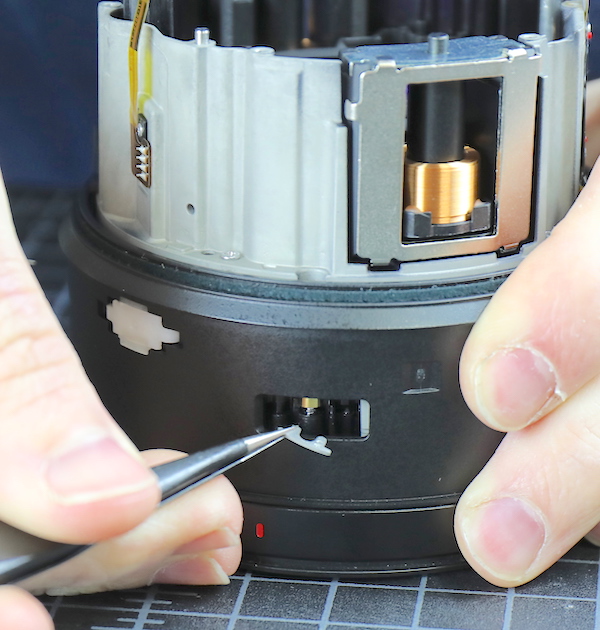

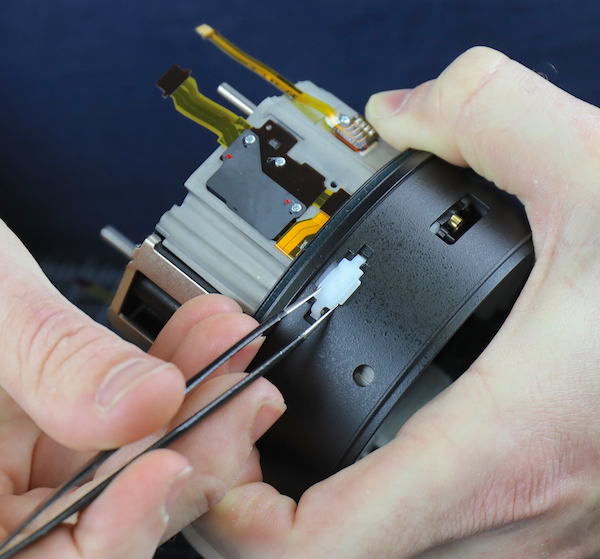

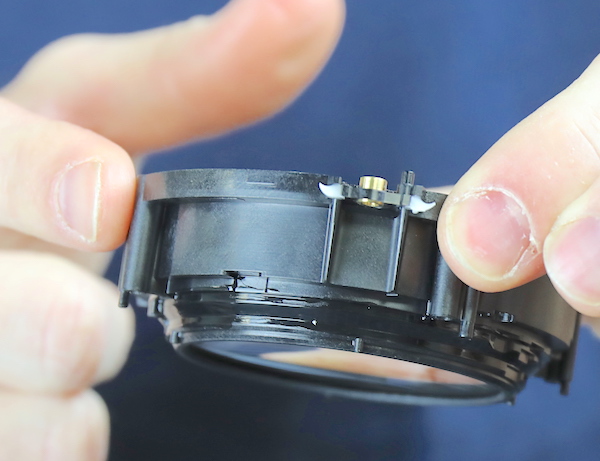

To get the focus ring off, we have to remove the white plastic sliders. These are glued so we’ll wait here for 20 minutes while the alcohol soaks in…… then pull them off.

Lensrentals.com, 2019

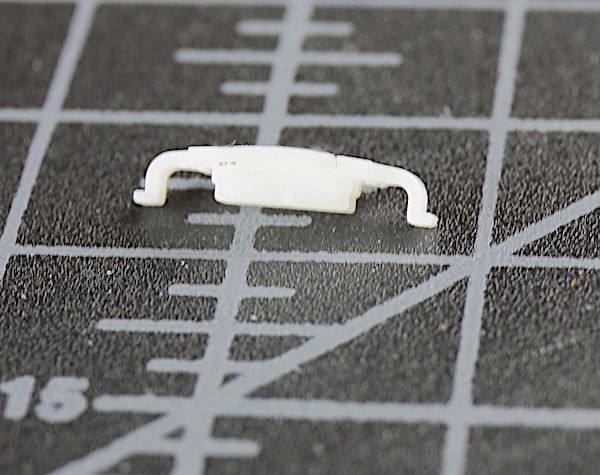

These seem to serve two purposes, they slide in grooves to keep the focusing ring in place but also are kind of springy, so they probably provide a little smooth resistance when turning the ring.

Lensrentals.com, 2019

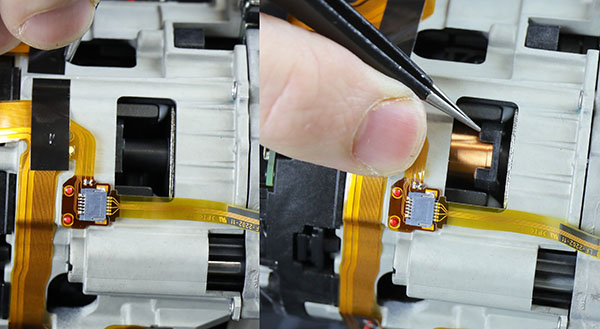

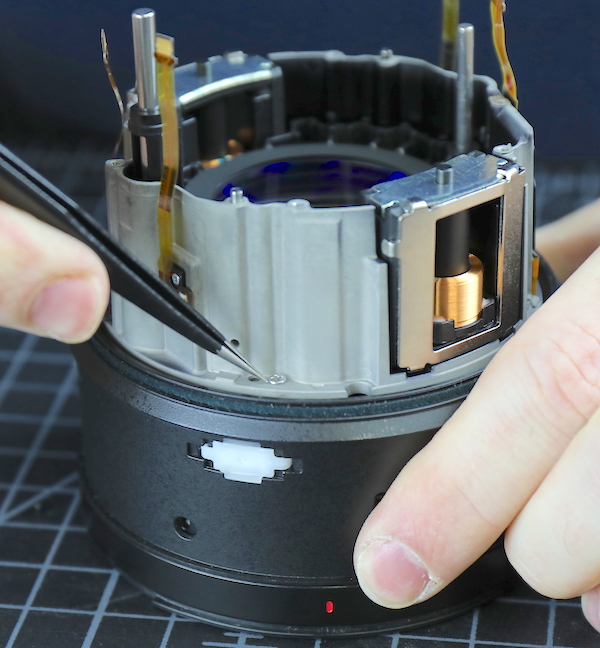

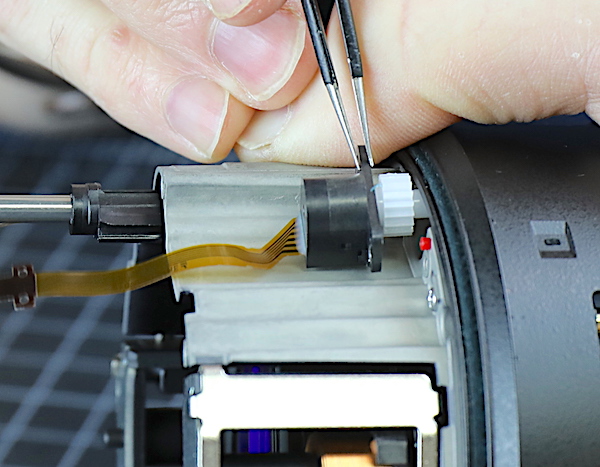

One last bit of disassembly; there is a focus position gear sensor that has to come off so the barrel can slide back. When you turn the focus ring, you’re actually turning this sensor which sends signals to the focus motors.

Lensrentals.com, 2019

Lensrentals.com, 2019

Lensrentals.com, 2019

It turns out those screws that were so obvious earlier actually hold the second group in place.

Lensrentals.com, 2019

There’s also a bit of glue, or possibly just sealant, around the second group, too. Since the element fell right out once the screws were removed we’ll go with sealant, since that sounds better than ineffective glue.

Lensrentals.com, 2019

The second group is a hefty bit of glass; I’m assuming three elements.

Lensrentals.com, 2019

Now everything is out of the way, and we can look down at the front of the focusing group. It’s pretty obvious the first element of the focusing group (at least) is out of place; the light shield has been pushed up at the top of the picture.

Lensrentals.com, 2019

Here’s a bit closer view in case you couldn’t see it above. You can see the light shield is flat along the right side of the picture but bulging up at the top where the element is shoving it up. This is probably a millimeter of tilt in a place where 0.1mm would be catastrophic optically.

Lensrentals.com, 2019

We peeled back the light shield to look underneath.

Lensrentals.com, 2019

And it’s obvious this is not just a ‘pop it back in place’ kind of issue like we’ve seen with some lenses. All the glue would need to be removed, and the element repotted. We thought it best to leave this job to the manufacturer, rather than potentially damage a part that’s we can’t purchase a replacement for.

Lensrentals.com, 2019

Conclusions

First, let me be clear, this is an isolated incident; we haven’t seen this problem with any other copies of the Sony 135mm GM (and we have a lot of them). Elements come unglued sometimes. It’s rare, but we’ve seen it occasionally with lenses from every brand. Just to be proactive, we notified people we work with at Sony so they could be on the lookout for any pattern and they’re probably going to return this copy to Japan for a closer look.

Don’t get paranoid about your lens; this isn’t a subtle thing. One minute it was taking beautiful pictures; the next minute every picture looked like a fog bank. It would NOT be something where you think ‘I wonder if this corner is soft’. It would be a ‘WTF just happened to my lens’ moment.

Now let’s get to the fun part, the teardown. This is a very well made lens. It IS built like a tank with robust magnesium alloy barrels, lots of long thick screws holding things together and nothing flimsy to be seen. The electromagnetic focusing motors, which were a weakness a few years ago, are now built like you could pull trucks out of ditches with them.

The more subtle stuff, things like the neatly laid out flexes and reassembly markers, indicate to me that a lot of care was taken in designing this lens. Nothing has that ‘we can stuff that in this nook over here’ look.

It’s a great lens optically that is very well built.

Roger Cicala and Aaron Closz

Lensrentals.com

July, 2019

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

Phillip Olson

-

Patrick Chase

-

Chris Albert

-

Thanh Tran

-

Don Lindell

-

Bob Locher

-

ntn_labs

-

Roger Cicala

-

HB Photo

-

HB Photo

-

Hunter45

-

Love Life

-

Roger Cicala

-

Lacknafta

-

Keiki Alexandra Bailey

-

Pox

-

Roger Cicala

-

MisterWU

-

Jonas

-

Andreas Werle

-

Roger Cicala

-

Roger Cicala

-

Nick Podrebarac

-

KeithB

-

Roger Cicala

-

Roger Cicala

-

KeithB

-

Vladimir Gorbunov

-

J.L. Williams