Equipment

Investigating the Canon R5 Heat Emission

ADDENDUM: I should have mentioned in the text, all testing was done at 73°F (22.75C) ambient temperature.

Lots and lots of people are talking about Canon R5 heat cut-offs. The discussions range from technical discussions about heat generation, cooling methods, and firmware protocols to strident conspiracy theories.

I only know a little bit about heat:

- Electronics give off heat when they’re working.

- Heat fries chicken, which is good, and fries electronics, which is bad.

- You can get rid of heat by conduction (flowing through nearby materials), convection (circulating through gas or fluids), and radiation (which mostly occurs at high temperatures). We know from the teardown that the R5 is tightly sealed, so we have to figure that convection doesn’t play much of a role.

As a repair and QA oriented person, I hate bricking cameras. So I’m less interested in coaxing the camera into working hotter (see point 2) and more interested in how the heat gets out. When we did the teardown of the Canon R5, we saw some metal heat sink/transfer plates that would conduct heat away from specific chips, but once the heat sinks get hot, then what happens? That’s what I was interested in.

This is not rocket science; there are people far more qualified than me talking about chip operating temperatures, the thermal flow of various substances, firmware cool-down cycles, and stuff like that. (There are also people far less qualified than me talking about those things.) I have nothing to add to either of those discussions, and I don’t intend to get into a fracas about it.

This is just some fundamental stuff about how heat leaves the camera—because to my simple mind, getting the heat out of the camera is the end-all, be-all. Tweak heat flow as much as you like inside, and maybe you’ll gain a few minutes of this or that. But eventually, the heat has to get outside, or the camera needs to shut down. I do need to point out that the heat flow with the back off has nothing in common with the heat flow with the back on, so I’m doing this with fully assembled cameras.

First Step

We got a Canon R5 running V1.0 firmware, slapped a CFx card in, put it in 8K mode, and ran it to temperature cut-off, using some industrial thermometers to see where heat left the camera.

With the lens on, and the camera sitting on a table, all covers closed and LCD folded against the camera back but not on we ran it for 18 minutes before getting a temp warning. The hottest part of the camera was the back behind the LCD door (43°C / 109°F), followed by the rear body around the command/set dials and the area of the grip where you rest your thumb (40°C / 104°F). The bottom plate around the tripod socket reached 38°C / 100°F.

The top, front, and sides didn’t warm up much at all; most of the camera was around 30°C.

We redid things with the LCD moved to the open position, away from the camera. This time that area on the back of the camera was a bit cooler, 39.5°C / 103°F, but nothing else changed much. So a few takeaways: First, leaving the LCD open lets the camera radiate heat a bit better, which is pretty logical, but not better enough to prolong recording time. (We did use the same CFx card for both runs.)

Next, we waited until the camera cooled enough to record again and restarted. The only interesting part of this was the second shut down occurred at a degree or two lower external temps than the first. Is this because of the delay in getting residual heat out of the insides? The inside should be hotter than the outside, because thermodynamics, but I couldn’t measure how significant that difference was.

At this point, we decided that the thermometers we were using were reading from a 1cm² area, which was kind of a blunt tool. So I got a little FLIR IR camera, spent some time checking it’s readings against both of the thermometers we used, and decided it was just as accurate and gave us a lot more information. Plus, cool pictures that are more fun to look at than rows of tables.

The Chassis and Shell

The chassis and shell of most cameras have been developed for years to be strong and light (most manufacturers use similar material). I’ve never thought they conducted heat well, but I didn’t know for sure.

So we took a shell off to test this a bit. Just simple stuff; I used a narrow-gauge heat gun to heat the shell and see what happened.

First, we heated the inside of the shell with rubber intact and tested the temperature on the other side. We found that the shell is indeed not a great heat conductor. Heating the inside up to 180° F / 82°C the outside got up to 160° F, but with several seconds delay. With the rubber grip applied the difference was, as you would expect, a bit longer, and the outside reached about 150°.

Then we heated one corner of the shell looked to see how far the heat spread. We knew heat crossed the 2mm thickness of the shell slowly, so I figured it wouldn’t conduct heat to other parts of the shell very well. For once, I figured right.

We had to go back to our industrial thermometers for readings here; the spectrum was more than our little camera could handle. But I’ve got that bottom corner heated up to 180° F, the rest of the shell isn’t very hot at all.

Lensrentals.com, 2020

I kept the corner hot for a few minutes, and we did get some local spread, but I’m not sure if some of that was leakage from my heat gun. It’s very clear, though, that the shell material doesn’t spread heat especially well. If this was aluminum or copper, the whole shell would have heated up. Obviously, it does pass heat out of the camera to some degree, but it sure doesn’t act as a heat sink or anything.

Lensrentals.com, 2020.Hot

One other point of interest, the shell held heat pretty well. Even exposed to air, it was over 10 minutes before it cooled down to room temperature. This kind of poses the question that if heat isn’t getting out of the shell very well, then how does the heat get out?

Looking at the Heat

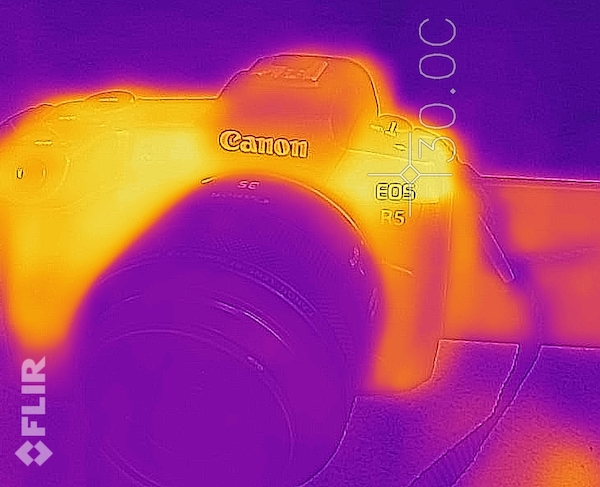

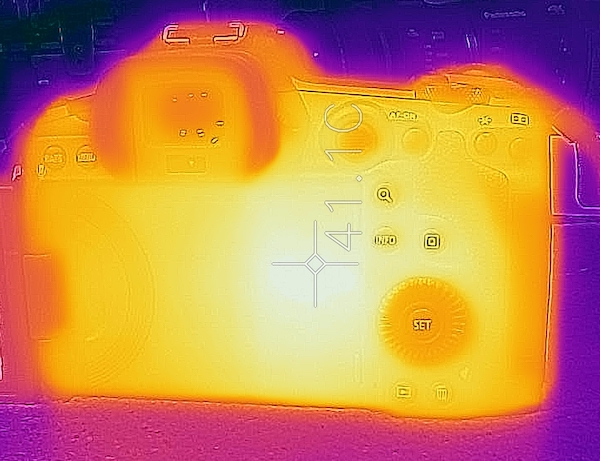

We got another Canon R5 with firmware v1.0, put a CFx card in, opened up the LCD, and started recording 8k again. Within a few minutes, we found our warm spot on the back of the camera.

Lensrentals.com, 2020

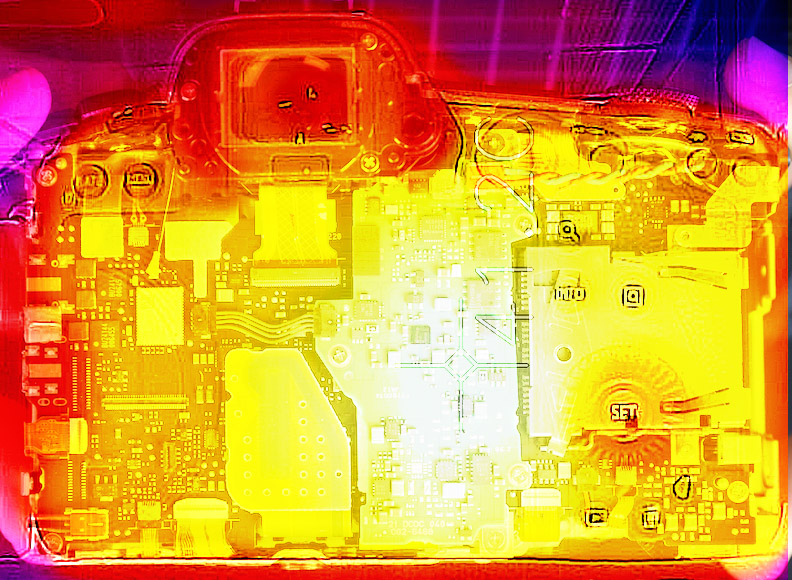

I overlaid an image from our teardown on the thermal image to show what’s right below there. Duh, the area over the processor and SDRAM cards.

Lensrentals.com, 2020 Please note, because someone is going to claim otherwise: this is NOT an image with the back off. It’s an image of inside of the camera overlaid on the heat image to correlate location.

There was a little warmth on the front.

Lensrentals.com, 2020

The top remained relatively cool. I had wondered, with the camera sitting on its base, if there might be some ‘heat rising in air’ effect. But then, as the teardown showed, there’s not a lot of air in there. We seem to be seeing a ‘viewfinder blocks heat transfer’ effect.

Lensrentals.com, 2020

The bottom of the camera got a bit warmer, so it seems like the heat sink that’s connected to the metal tripod plate is sending some heat that way.

Lensrentals.com, 2020

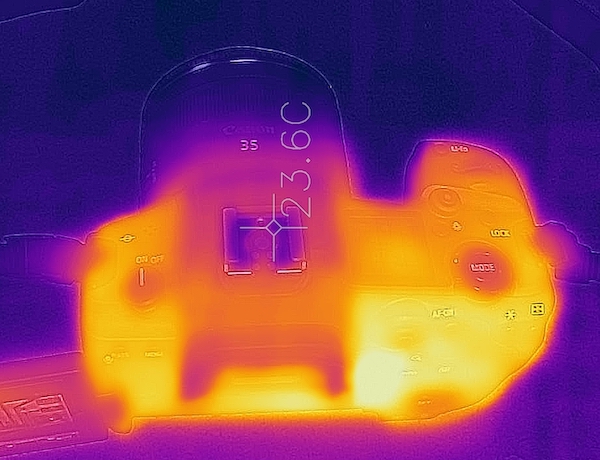

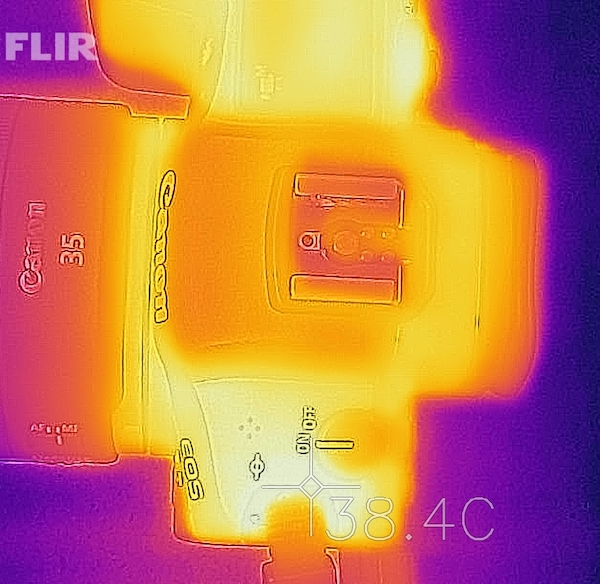

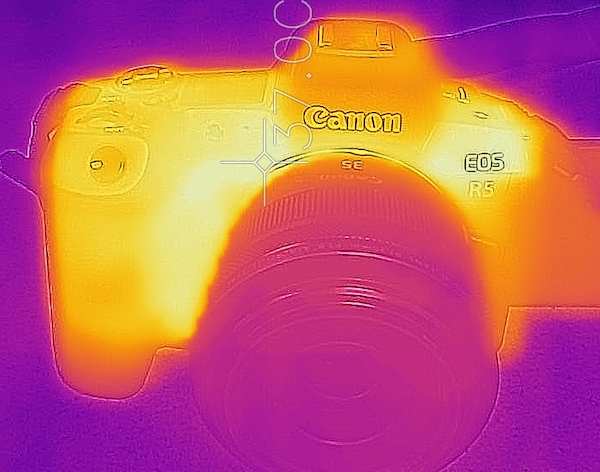

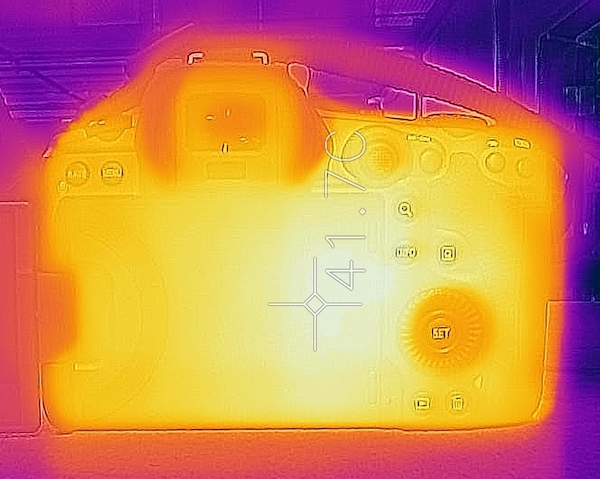

After a while, the warm fuzzies started giving way to the screaming heaties. Here are some pics showing how the camera was lighting up as we approached thermal cut-off, at 20 minutes.

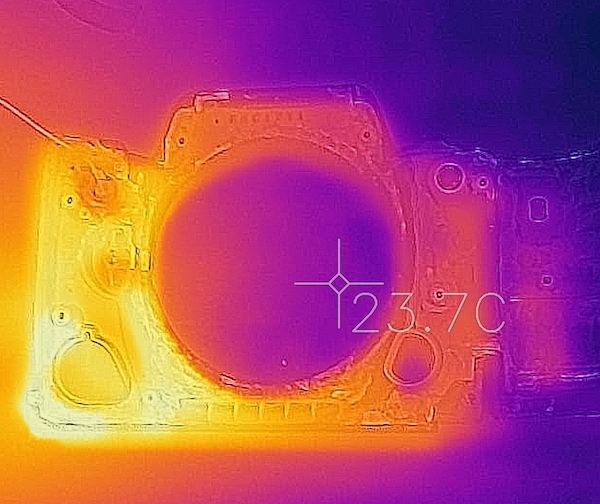

The bottom is my favorite in this group. Notice how every screw that goes into the metal tripod plate is lighting up. The lens mount ring is pretty hot, too, with a temp of 38°C. The tripod socket seems to actually be a bit cooler than the rest of the bottom plate. I’m not sure why, perhaps a different metal, a gasket where it connects to the tripod plate, or possibly because it sits in a little air pocket inside the camera.

Lensrentals.com, 2020

The top assembly still isn’t very hot in general, but both of the metal camera-strap lugs are spewing heat.

Lensrentals.com, 2020

Lensrentals.com, 2020

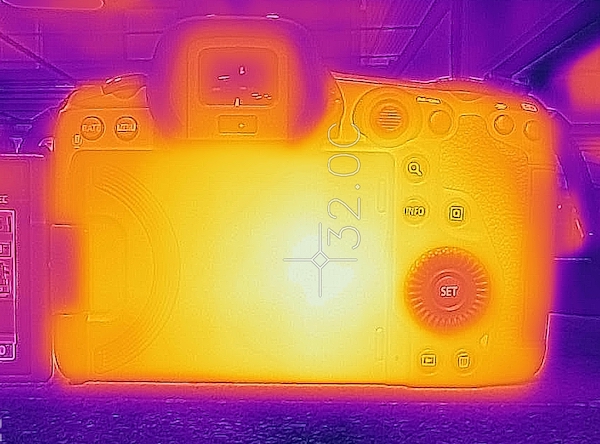

The hot spot at the back peaks out at 42°C and the entire back warms up to some degree.

Lensrentals.com, 2020

We have some significant heat radiating from the front, too, particularly around the lens mount area and in the corner above the card doors.

Lensrentals.com, 2020

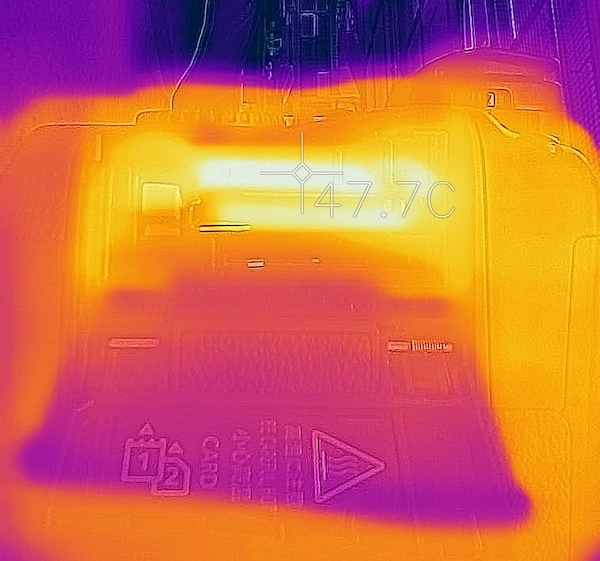

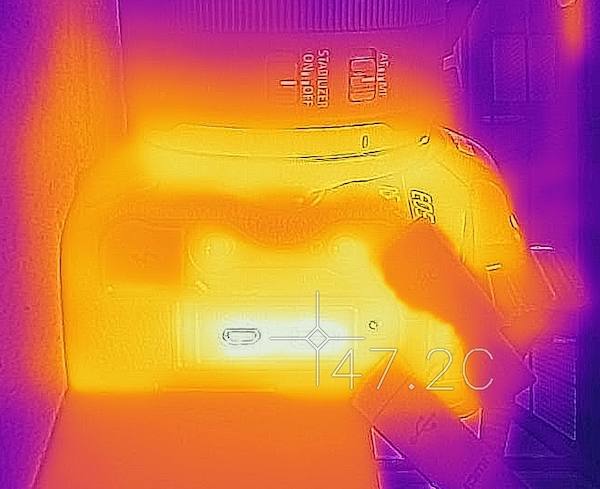

The hottest spot in the camera, though, was clearly the CFx slot. After the card was ejected it was about 48°C.

Lensrentals.com, 2020

After Firmware Upgrade

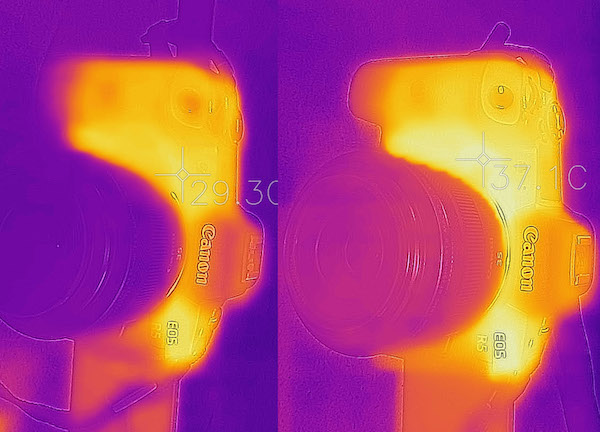

We got a longer run after upgrading to V1.1, getting 25 minutes before cut off, but at the expense of slightly higher temps. (Full disclosure: I didn’t tell Joey to use the same CFx card in every run, so that may have changed.)

Not surprisingly, the longer run times came with slightly higher temperatures. Only a half degree hotter at the back.

Lensrentals.com, 2020

And at the bottom.

Lensrentals.com, 2020

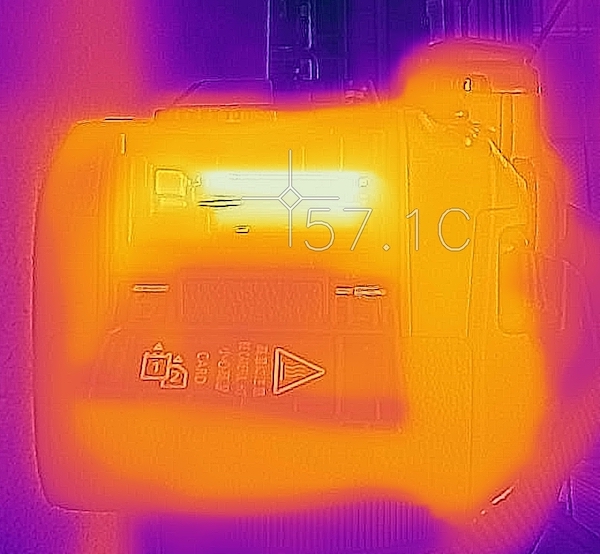

The card slot is quite a bit hotter, though.

Lensrentals.com, 2020

Of course, the card was hot, but I figured someone was going to ask, so here. It reads cooler than the slot, but it took a couple of seconds to get it out and get the image, so I’m not sure if it actually was.

Lensrentals.com, 2020

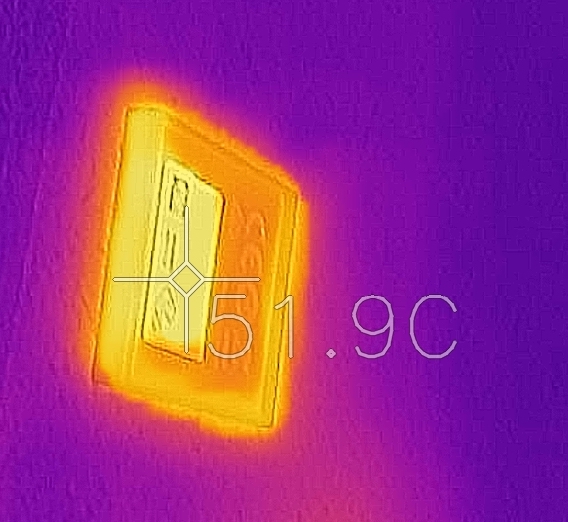

This made me curious about how hot the I/O ports were. The port covers had remained closed during recording. The ones on the mainboard were quite hot; those on the sub-board not hot at all.

Lensrentals.com, 2020

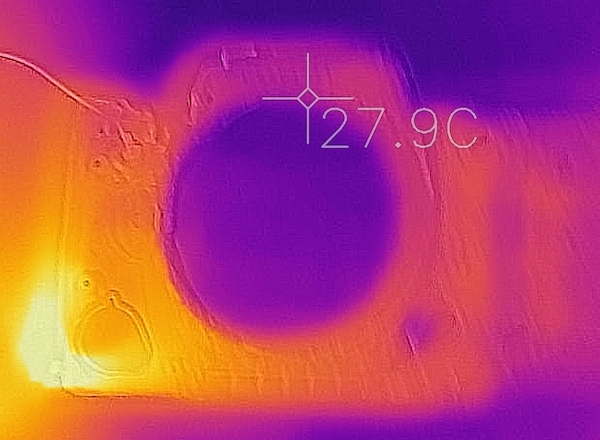

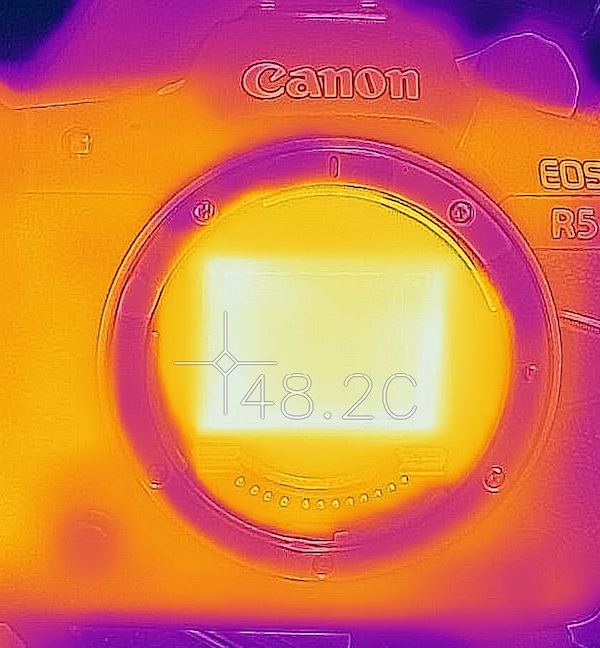

The sensor radiated quite a bit of heat, too. It wasn’t as hot as the card slot, but has a bigger surface area. It may also be that the metal in the IBIS unit is hot and that’s leaking out through the sensor area.

Lensrental.com, 2020

A friend, who wants no part of the inevitable arguments a Canon R5 heat post causes these days and will therefore remain nameless, was kind enough to read the internal temperature from a raw file taken when we were doing these other measurements. The EXIF recorded internal temperature was 63°C (I originally typoed this as 61C, it has since been corrected), which is hotter than even the CFx card slot.

I don’t know which temperature sensor the EXIF reads or where it is located. But somewhere inside the camera is hotter than the CFx card, and way hotter than the outside of the camera. There has to be a gradient, of course, for heat to flow. Still, this seems to indicate heat isn’t flowing easily.

So What Did We Learn Today?

Odds and ends mostly. The answer to the question “how does heat leave the camera” is basically not very well, and mostly via the metal parts. ‘Mostly’ as in the temperature is higher there, so I assume the heat flows easiest to those metal parts. I don’t have the math to figure out the actual caloric transfer, and the ‘not metal’ parts have a bigger surface area, so it may be that most of the calories may exit through the shell. The camera is hotter deep inside (the temperature sensor) than at the hottest exit points.

I am NOT a chip guy, but according to their faq, the Toshiba voltage converting chips have a suggested maximum operating temp of 60°C before they dramatically lose efficiency, and less efficiency means generating more heat. The CFx card slot was at 57°C and the internal temperature sensor at 61° C when things shut down. That could be a coincidence but may suggest Canon doesn’t think getting the inside much over 60° C is a good idea. I don’t know, but I’m a conservative guy by nature, so my personal decision is I’d prefer not to get the inside much hotter than that.

I’m not going to comment on how to improve heat transfer deep inside the camera; other people seem to be working on that. But the camera is a lot hotter inside than it is outside when it shuts down. If it doesn’t get heat out very well, it certainly can’t be expected to cool down quickly after it turns off from overheating. Cooling the outside of the camera should help a bit, but it’s not going to be very efficient.

Leaving the LCD opened away from the camera back, opening up the HDMI port cover, and saving to SD cards when possible (not an answer for 8K video, I get that) may all help get heat out of the camera while you’re using it. Still, I doubt it’s enough to make a significant difference in recording time. Removing the rubber grips might help a bit, too, but probably not a lot; the shell isn’t a great heat conductor.

Lensrentals.com, 2020

It seems likely that taking off the lens and opening the shutter, opening the card doors, and removing the CFx card will speed cool down. (I think several people have already discussed that online). But that’s all I can think of that might help a stock camera stay cool, and none of those are impressive thoughts.

Some people intend to do more aggressive things to extend recording time. It would certainly be possible, with some minor modifications, to connect the metal heat sink plates to the outside world. You might do so by just exposing the bottom tripod plate and attaching a sink to that. Of course you lose weather sealing, but it would be simple to try. I don’t know enough about the effectiveness of thermal transfer to say, but you could run thermal tape under all the bottom screws and bring it out through the bottom plastic cover and attach it to a heat sink. If that’s effective, adding some more paths to the two other heat plates in the camera might be even better.

You could also ventilate the camera to outside air fairly easily. There’s a large area in the body’s back plate that could be opened up; there’s no electronics under it. There are some smaller areas on the front plate where this could be done, too. It would be a fairly simple matter to take all the weather sealing out and make some leaking places for air to circulate. I honestly doubt some air circulation is going to have much of a cooling effect, but again, I don’t have this kind of maths. I bet some of the commenters will, though.

There’s also the issue that the camera is hotter deep inside. I suspect that when some third party does good work to improve heat transfer (where there is demand, an entrepreneur will fulfill it), that work will have to include some modifications of the internal heat flow. That won’t of itself be enough; you’ll still have to get the heat outside of the camera to accomplish much.

These kinds of things would make for a bigger, bulkier camera with no weather sealing—sort of a redneck 8K video camera.

Given the low price of the R5 compared to a dedicated video camera with these specs, I expect someone will probably do it. Not me, I’m out of the entrepreneur thing, and a lot of experimenting (AKA camera sacrifice) would need to be done to figure out the most efficient methods.

I just can’t imagine tossing a fan on it and / or making a few holes is going to be effective. Someone will Kickstarter the idea, of course, but that doesn’t mean it’s going to work. Someone is raising a bunch of money on Kickstarter and then not delivering a working product. Who would have thought that could happen.

And Now, We Shall Have the Speculations!

Speculation is not knowledge. Robert M. Price

For a long, long time, the engineers making photo cameras have been worried about better weather sealing and materials that are strong and lightweight. They have not been particularly worried about getting heat out of cameras.

A big camera has many different development teams, each doing its own thing when it designs a camera. Let’s guess that the team doing electronic and video capabilities managed to cram all this super video goodness onto chips. Surely the marketing team LOVED the idea.

Some other team probably said, ‘it’s gonna be hot in there’ and got told, ‘put in some heat sinks and transfers and do the best you can.’ That was done, we’ve seen it. Perhaps it could have been done better, but there was a lot of new stuff going into this camera, which probably meant a lot of compromises had to be made, and deadlines had to be met. (Actually, deadlines were missed, they always are, and the pressure mounted.) In the end, I bet that everyone agreed 15-20 minutes of 8k video was better than 0 minutes, and well, deadlines!

The body design team has been working towards the goal of light, strong, weather-resistant for about 15 years. A new casing material, openings to allow air (and therefore water) to flow through the camera, external heat sinks, that stuff wasn’t going to happen. Not only would you need to find new material, but you’d also need a new plant to make the parts and a redesigned assembly line, too. And nobody was going to hold up the release for another year while they redesigned things.

Is Canon going to “fix this” as people keep saying? I doubt that’s possible, and I really doubt Canon thinks it needs fixing. I believe they consider it primarily a photography camera that can shoot some video. There may be another tweak or two, but I speculate that operating temps have to be kept at some level, and that cool down is always going to be slow.

A firmware hack or update isn’t going to make the camera cool better; it’s going to allow it to work hotter. I think that probably isn’t a good idea, but I could be wrong. I’m wrong a lot. (Do you know what I do when I’m wrong? I say, “It looks like I was wrong about that.” Some of you all should try that. You’ll be surprised to find it’s not painful.)

Other people are certain this is a purposeful firmware crippling, and a hack will fix it. That will mean the camera can really operate at higher temperatures. It might be they are right. Things may work fine in there at 70°C or even 75°C (167° F).

Will the Canon R5ii someday have better heat management? It’s possible that Canon won’t give a damn since they consider this a photo camera with video capabilities, and it’s not a priority. I suspect, though, that Canon engineers are like me; they don’t like the idea of unescaped heat in a camera and will improve the heat flow on general principles. But that’s someday, and I’m living in today.

Joey Miller, Aaron Closz, and Roger Cicala

Lensrentals.com

This 11th day of the 9th year of 2020

A Note for Leaving Comments: We have polite discussions and disagreements here, backed by logic, facts, and, when possible, science. If you want to scream your viewpoints or make personal attacks on others, there are plenty of forums where that is the main method of communication; please take those comments there.

Another note for those about to suggest more tests: You can buy a nice little phone mounted IR camera for just a few hundred dollars. You should get one and do those tests. I’m like a squirrel, I have a short attention span and get bored easily. I’m over this heat stuff.

Author: Roger Cicala

I’m Roger and I am the founder of Lensrentals.com. Hailed as one of the optic nerds here, I enjoy shooting collimated light through 30X microscope objectives in my spare time. When I do take real pictures I like using something different: a Medium format, or Pentax K1, or a Sony RX1R.

-

CanonNews

-

Brandon Dube

-

Tnos Hosten

-

asad137

-

asad137

-

Ciaran

-

ftirguy

-

Brandon Dube

-

Jeff Sellenrick

-

Ciaran

-

asad137

-

Olandese Volante

-

Olandese Volante

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Roger Cicala

-

Brandon Dube

-

Brandon Dube

-

Cdave

-

David

-

Tnos Hosten

-

Cdave

-

Verochka Tzimmermann

-

Tnos Hosten

-

Brandon Dube

-

Tnos Hosten

-

Brandon Dube